Struggling to find complex titanium parts? Traditional methods can be slow and expensive. You need a faster, more flexible way to get the components your customers demand.

Yes, titanium alloys can be 3D printed, especially the popular Grade 5 (Ti-6Al-4V). Using a process called Selective Laser Melting1 (SLM), fine titanium powder is fused layer by layer to create strong, complex parts for industries like aerospace and medical, often surpassing traditional manufacturing capabilities.

A client of mine, Ahmed, who runs a metal distribution business in Turkey, recently asked me about this. He stocks materials for small manufacturers and wanted to know if 3D printing was a viable market for him. He, like many others, sees the potential but needs to understand the practical details. Let’s dive into the specifics, so you can see if this technology fits your business needs.

How are titanium alloys 3D printed?

Are you wondering how a solid metal part comes out of a machine? It seems complex, but the idea is simple. You need to know the core process to understand its benefits.

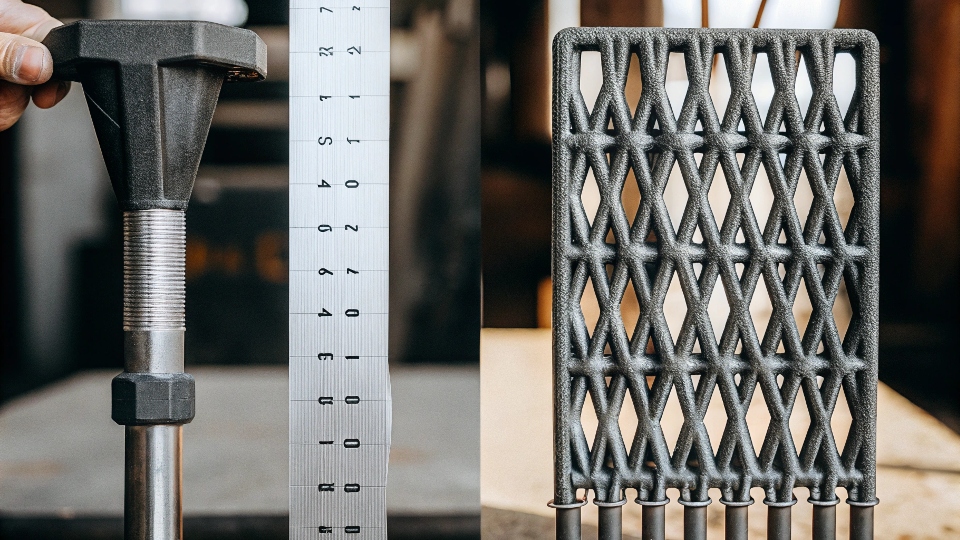

The most common method is Selective Laser Melting, or SLM. It uses a high-powered laser to melt and fuse metallic powders together, layer by layer. This process allows for the creation of intricate designs that are impossible with traditional casting or forging methods.

Based on my work with partners like Titonest Metal, the process starts with a digital 3D model. This file guides the printer. The machine lays down an extremely thin layer of titanium alloy powder, usually Ti-6Al-4V, which is valued for its strength and widespread use. A powerful laser then selectively melts the powder according to the digital blueprint. The build platform lowers, a new layer of powder is applied, and the process repeats until the part is complete. I’ve seen them mass-produce complex aerospace components and custom medical implants this way. The precision is incredible, and it opens up a world of possibilities for creating lightweight, strong parts that were previously too difficult or costly to make. This is why it’s a game-changer for many industries.

Looking for Reliable Titanium Bars?

Our titanium bars are available in various grades and specifications to meet the highest industry standards. Perfect for aerospace, medical, and industrial applications, ensuring quality and performance under the toughest conditions.

What metals cannot be 3D printed easily?

Thinking of expanding into 3D printing? You might assume any metal can be printed. But some materials present real challenges that can stop a project cold if you’re not prepared.

Not all metals are suitable for standard laser-based 3D printing. The main culprits are highly reflective metals like pure copper or certain aluminum alloys, and metals with very low melting points. Their properties interfere with the laser melting process, leading to poor results or failed prints.

I learned a lot about this from my collaborations with several additive manufacturing labs in Europe. They explained that highly reflective metals, like pure copper, bounce a lot of the laser’s energy away instead of absorbing it. This means the powder doesn’t melt properly or evenly. You get an unstable melt pool, which results in a weak, porous part. On the other end, some alloys with low melting points can vaporize too easily under the intense heat of the laser, which also disrupts the process. To get around these issues, these labs have to develop highly specialized parameters. Sometimes they even create new blended powders, mixing the difficult metal with another material to improve its energy absorption and stability during printing. It’s a reminder that material science is just as important as the printing technology itself.

How strong is 3D printed titanium?

You might think 3D printed parts are weaker than forged ones. This is a common concern. But is it true? You need to know the real strength to trust it for critical applications.

3D printed titanium is surprisingly strong, often meeting or even exceeding the strength of traditionally forged parts. With proper post-processing, its mechanical properties are reliable enough for demanding sectors like aerospace, defense, and medical implants, where failure is not an option.

We regularly perform tests on the parts my partners produce. Using ASTM E8 tensile tests, we’ve seen 3D printed Ti-6Al-4V components achieve tensile strengths up to 895 MPa. To put that in perspective, that is very competitive with wrought or forged versions of the same alloy. The real advantage comes after a post-processing step called Hot Isostatic Pressing2 (HIP). This process uses high heat and pressure to eliminate any internal micro-pores that might have formed during printing. Our fatigue tests show that HIP-treated components have a fatigue life up to 15% longer than traditional forgings. This means they can withstand more stress cycles before failing.

Here’s a simple breakdown based on our data:

| Property | Traditional Forged Ti-6Al-4V | 3D Printed Ti-6Al-4V (As-Printed) | 3D Printed Ti-6Al-4V (HIP Treated) |

|---|---|---|---|

| Tensile Strength | ~900 MPa | ~895 MPa | ~930 MPa |

| Density | ~99.5% | ~99.7% | >99.9% |

| Fatigue Life | Baseline | Comparable | Up to 15% longer |

This data is why major aerospace firms and medical device companies are adopting this technology. They get the design freedom of 3D printing without sacrificing strength or reliability.

What other common alloys can be 3D printed?

So, titanium is a great candidate for 3D printing. This might make you wonder what other metals are on the table. Knowing this can help you serve a wider range of customer needs.

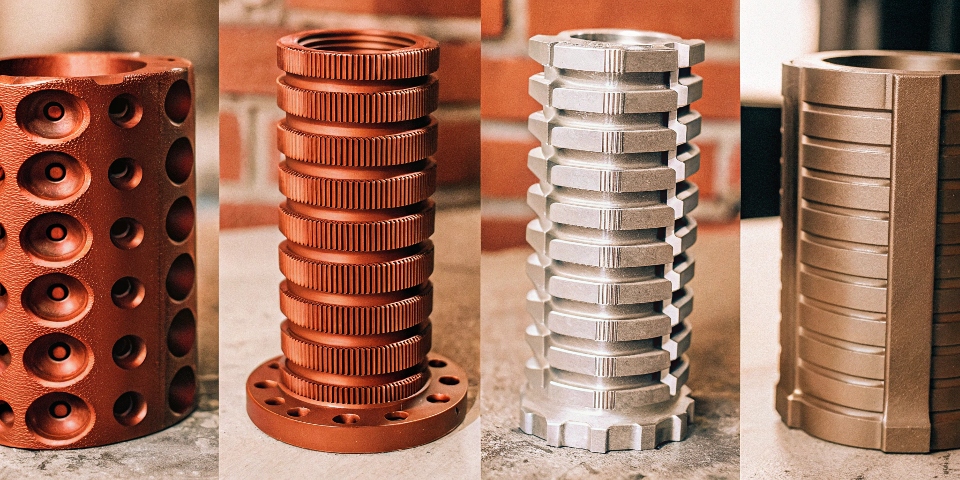

Yes, many alloys beyond titanium are routinely 3D printed. These include various stainless steels, cobalt-chrome alloys3, nickel-based superalloys like Inconel, and different types of aluminum alloys. Each offers unique properties for specific industrial applications, from medical implants to jet engine components.

In my work, I see a few alloys come up again and again. Besides the workhorse Ti-6Al-4V, Cobalt-Chrome (CoCr) alloy powders are very popular, especially for medical implants like knee and hip replacements. They have excellent biocompatibility and wear resistance. My partners provide CoCr powders that are certified under ISO 13485, the medical device standard, which is critical for clients in that sector. We also see huge demand for nickel-based superalloys like Inconel 718. It retains its strength at very high temperatures, making it perfect for jet engine and gas turbine parts. Stainless steel powders, like 316L, are another staple. They are used for everything from tooling and fixtures to marine and food-grade applications due to their corrosion resistance. All these powders, when used in SLM, must meet strict standards, like aerospace and military certifications, to ensure the final parts are strong, reliable, and safe for mass production.

Conclusion

In short, 3D printing with titanium and other alloys is no longer a future concept. It is a powerful, reliable manufacturing method available today for creating strong, complex parts.

Looking for Reliable Titanium Wire for Your Projects?

Explore our selection of premium titanium wire, perfect for various applications in aerospace, marine, and industrial settings. Find the right specifications and grades suited to your needs, ensuring durability and performance.

-

Learn about SLM, a revolutionary 3D printing method that creates complex titanium parts with precision. ↩

-

Learn how HIP improves the strength and durability of 3D printed components, making them reliable. ↩

-

Find out why cobalt-chrome alloys are favored for medical applications due to their biocompatibility. ↩