Struggling to join titanium with other metals? The wrong method creates weak, brittle joints that fail under pressure. But there are specialized techniques that work for a solid bond.

Yes, you can weld titanium to other metals like steel or copper, but not with traditional methods. You need special processes like explosion welding1 or bimetallic transition joints2. These are essential to avoid creating brittle compounds that compromise the joint’s strength and reliability.

This is one of the most common questions I get. A client of mine, Ahmed, runs a metal distribution business in Turkey. He needs to give clear advice to his customers, who are often small manufacturers. They want to know if they can just use their existing equipment to weld a titanium part to a stainless steel one. The answer isn’t a simple yes or no. It really depends on the application and using the right method to get a strong, safe result. Let’s break down what actually works and what you must avoid.

What can you weld titanium with?

You have a special project that needs to join titanium to another metal. Using the wrong combination can lead to total material failure. Understanding what works is the first step.

Titanium can be joined to metals like steel, copper, and aluminum, but not directly through fusion welding. You must use an intermediate piece or a special process. These methods prevent a brittle weld, ensuring a strong bond for demanding industrial applications.

Directly melting two different metals together, like titanium and steel, often fails. This is because they are not metallurgically compatible. When they melt and mix, they form very hard but brittle layers called intermetallic compounds3. These layers crack easily under stress. So, how do we get around this? We use methods that join the metals without creating these weak points.

There are three primary solutions I recommend:

Connection Methods for Dissimilar Metals

| Method | Description | Best For |

|---|---|---|

| Bimetallic Transition | A pre-made part with titanium on one end and another metal (like steel) on the other. You then weld steel-to-steel and titanium-to-titanium. | Structural parts in chemical plants, marine applications, and aerospace. |

| Explosion Welding | Uses a controlled explosion to force two metal plates together. The immense pressure creates a solid-state bond without melting. | Large, flat plates for shipbuilding or pressure vessels. |

| Brazing/Soldering | Uses a filler metal with a lower melting point to join the two parts. It’s more like gluing with metal than true welding. | Non-structural parts where high strength is not the main goal. |

For most of my clients, bimetallic transition joints are the most practical and reliable choice.

Can I weld titanium to stainless steel?

Are you thinking about welding titanium directly to a stainless steel part? This common mistake creates a weld as brittle as glass, just waiting to crack under pressure.

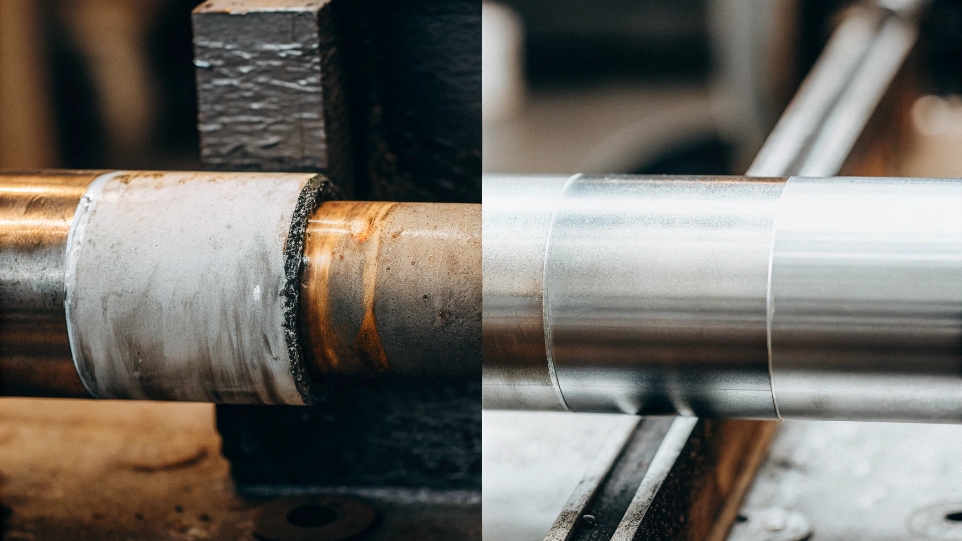

Directly welding titanium to stainless steel is a very bad idea. The process forms extremely brittle intermetallic compounds, specifically TiFe and TiCr, at the joint. For a reliable connection, you absolutely must use a bimetallic transition piece designed for the job.

Let me explain exactly why this fails. When you melt titanium and the iron or chromium in stainless steel together, their atoms mix and form new materials. These iron-titanium (TiFe) and chromium-titanium (TiCr) compounds are incredibly hard but have no flexibility. The slightest vibration or change in temperature can cause them to fracture.

I remember a client in the chemical processing industry who learned this the hard way. They tried to save a little money by welding a titanium pipe directly to a stainless steel flange. The weld looked fine, but it failed in less than a month, causing a dangerous leak and a very expensive shutdown. We worked with them to replace it using proper titanium-steel transition joints. Now, the connection is safe and reliable. This story is why I always tell my partners like Ahmed to stress the importance of using the right components from the start. A small saving upfront can lead to a huge cost later.

How to attach titanium to titanium?

Welding titanium to itself seems like it should be simple. But one tiny mistake, like a bit of air getting to the weld, can ruin the entire piece. The secret is keeping everything perfectly clean and shielded.

To weld titanium to titanium, you must use a method like TIG welding4 within a pure inert gas atmosphere. Pure argon is the standard shielding gas. This shield protects the hot titanium from oxygen, nitrogen, and hydrogen in the air, which cause severe embrittlement.

When you weld titanium to itself, success depends on two things: extreme cleanliness and perfect gas shielding. First, the metal must be spotless. You need to wipe it down with a solvent like acetone to remove any oils or grease. Then, you should use a stainless steel brush—one that is only ever used for titanium—to remove the surface oxide layer right before you weld.

Second, and most importantly, is the argon gas shield. Hot titanium loves to react with air. You need to protect it. This means using:

- Primary Shielding: A good flow of argon from the welding torch. Using a large ceramic cup, called a gas lens, helps the gas flow smoothly over the weld pool.

- Secondary Shielding: A "trailing shield" that follows the torch to keep the cooling weld protected until it is no longer reactive.

- Back Purge: If you’re welding tube or pipe, you must fill the inside with argon to protect the back of the weld.

The color of the finished weld tells you if you did it right. A good weld will be a light straw or shiny blue color. A bad, contaminated weld will be dark blue, grey, or covered in a white powder.

Titanium Weld Color Guide

| Weld Color | Quality | Action |

|---|---|---|

| Light Straw / Shiny Blue | Good | No action needed. This is a strong weld. |

| Dark Blue / Purple | Marginal | Use with caution. May have some contamination. |

| Grey / Chalky White Powder | Unacceptable | Contaminated and brittle. Must be cut out. |

Why is titanium so difficult to weld?

The idea of welding titanium can seem intimidating. Its reputation for being difficult can scare people away from using it. But the challenge isn’t a mystery, it’s just chemistry.

Titanium is difficult to weld because it is extremely reactive with gases like oxygen, nitrogen, and hydrogen at high temperatures. This contamination makes the weld brittle and weak. It demands extreme cleanliness and a perfect inert gas shield to protect the molten metal.

The difficulty in welding titanium comes down to a few key properties. Once you understand them, the process makes sense. I always tell my clients, "Don’t be scared of it, just respect it." You need to control the environment carefully.

The primary challenges are:

-

High Reactivity: This is the biggest issue. At welding temperatures, titanium will pull oxygen and nitrogen right out of the air. This is why a perfect argon shield is not just a suggestion, it’s a requirement. I tell welders to think of hot titanium like a hungry sponge for air. This simple idea helps everyone understand why the shielding is so important.

-

Need for Cleanliness: Any surface contamination, like oil from your fingerprints, dust, or paint, will get absorbed by the molten titanium. This creates pores and weak spots in the weld. The material must be cleaned spotless just before welding begins.

-

Low Thermal Conductivity: Titanium doesn’t spread heat well, unlike aluminum or steel. Heat stays concentrated right at the weld. This means the welder has to use different techniques for heat control and travel speed to avoid overheating the metal and creating a large, weak heat-affected zone5.

Summary of Welding Challenges & Solutions

| Challenge | Why It’s a Problem | Solution |

|---|---|---|

| Reactivity with Air | Absorbs oxygen and nitrogen, causing a brittle weld. | Use an inert argon gas shield (torch, trailing, and back purge) |

| Surface Contamination | Oils, dirt, and oxides get into the weld, causing defects. | Degrease with solvent and use a dedicated stainless steel brush. |

| Low Heat Conductivity | Heat stays concentrated, risking overheating and a weak zone. | Adjust welding technique, heat input, and travel speed. |

Conclusion

Welding titanium requires special knowledge, whether joining it to itself or other metals. Proper technique and materials are key to avoiding brittle, unreliable joints and ensuring project success.

-

Learn about this unique method that creates strong bonds without melting the metals. ↩

-

Explore how these joints provide reliable connections between dissimilar metals, ensuring strong welds. ↩

-

Understanding these compounds helps in avoiding brittle welds when joining different metals. ↩

-

TIG welding is essential for titanium; learn the techniques for successful results. ↩

-

Understanding this zone helps in controlling heat input for better weld quality. ↩

[^5]](https://titonestmetal.com/wp-content/uploads/2025/07/to-weld-titanium-to-titanium-you-must-use-a-met.jpg)