Introduction to Titanium

-

Titanium is a metallic element with atomic number 22, positioned in the periodic table among the transition metals, and is known for its relatively low density, high strength, and excellent corrosion resistance.

-

It is a transition metal with a high strength-to-weight ratio, making it ideal for various industrial applications.

-

Titanium metal is widely used in aerospace, medical, and marine industries due to its unique combination of physical and mechanical properties.

-

The discovery of titanium dates back to 1791, when titanium was discovered in black sand, which contained titanium in the form of metal oxides. Titanium is widely distributed in the Earth’s crust, commonly found in igneous rocks and other geological formations.

-

Titanium’s density is approximately 4.506 g/cm³, which is significantly lower than other metals like steel and nickel, highlighting its relatively low density and making it suitable for high-performance applications.

-

Properties of Titanium

Pure titanium has a high melting point, low thermal conductivity, and excellent corrosion resistance due to the formation of a protective oxide layer. At room temperature, titanium has a hexagonal close packed crystal structure, which transforms to a body centered cubic structure at elevated temperatures.

Titanium alloys exhibit superior corrosion resistance, high tensile strength, and low density, making them suitable for aerospace and marine applications. High purity and commercially pure titanium are essential for advanced applications requiring superior strength and corrosion resistance, such as aerospace and military uses, where pure metal titanium is highly valued.

The physical properties of titanium, such as its strength-to-weight ratio and electrical conductivity, make it an attractive material for various industries. Titanium is a strong metal with one of the highest strength-to-weight ratios, making it significantly lighter and lower density than many other metals. Titanium’s density is about 4.5 grams per cubic centimeter (g/cm³) or 0.163 pounds per cubic inch (lb/in³), which is considerably lower than steel and nickel, and its density related properties enable performance improvements and design flexibility in aerospace, medical, and automotive industries.

Titanium’s mechanical properties, including its tensile strength and hardness, can be enhanced by alloying with other elements. Titanium is used as an alloying element and alloying agent in steel and other alloys to refine grain size and reduce carbon content, improving mechanical properties and corrosion resistance. The addition of different elements to titanium alloys can further tailor their properties for specific applications.

The density of titanium is a critical factor in its applications, as it provides a favorable balance between weight and strength. Its light weight and lower density make it ideal for high-performance, durability-sensitive environments. Additionally, titanium and its alloys have notable electrical resistivity, which is an important consideration in engineering and material selection.

Comparison with Other Metals

-

Titanium’s density strikes a balance, positioning it between lighter metals like aluminum and heavier metals like steel and nickel.

Metal

Density (g/cm³)

Tensile Strength (MPa)

Primary Advantages

Titanium

4.506

440–1,000+

High strength-to-weight ratio, corrosion resistance

Steel

7.85

250–870

High strength, cost-effective

Aluminum

2.70

70–700

Lightweight, excellent thermal conductivity

Nickel

8.90

520–1,400

High corrosion resistance, toughness

-

Titanium’s density is lower than that of steel and nickel, but higher than that of aluminum, making it an intermediate material in terms of weight. Titanium’s density makes it significantly lighter than steel, contributing to its popularity in weight-sensitive applications.

-

Compared to other metals, titanium has a unique combination of high strength, low weight, and excellent corrosion resistance.

-

The strength-to-weight ratio of titanium is significantly higher than that of most metals, making it ideal for aerospace and automotive applications.

-

Titanium’s thermal conductivity is lower than that of copper and aluminum, but its corrosion resistance is superior to many other metals.

-

The properties of titanium make it a popular choice for applications where high strength, low weight, and corrosion resistance are required.

Applications of Titanium

-

-

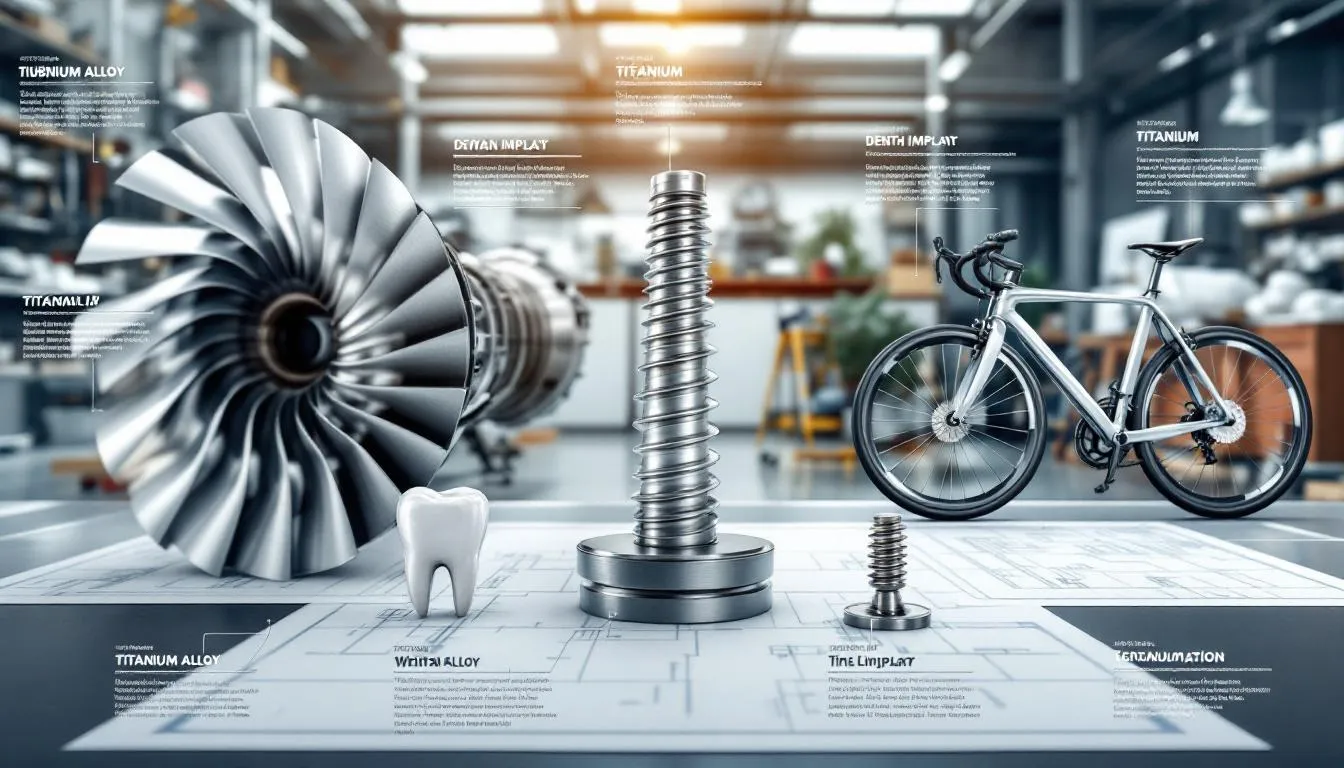

Titanium is widely used in the aerospace industry for aircraft engines, frames, and other aerospace components due to its high strength-to-weight ratio and corrosion resistance. Titanium is especially valued in jet engines and other parts exposed to elevated temperatures, where its protective layer of oxide resists corrosion and maintains durability.

-

Titanium alloys are used in medical implants, such as orthopedic implants and dental implants, due to their biocompatibility and corrosion resistance. Titanium is also commonly used in joint replacements, providing long-term integration with bone and internal stability.

-

Marine applications, including propeller shafts and heat exchangers, also utilize titanium due to its excellent corrosion resistance in seawater. Titanium’s durability in marine environments makes it ideal for components exposed to harsh and corrosive saltwater conditions.

-

The chemical processing industry uses titanium equipment and components due to its resistance to corrosion and high strength. Titanium dioxide is widely used as a pigment in coatings and plastics, while titanium tetrachloride serves as an important intermediate in titanium production, is used as a catalyst, and is employed in the creation of smoke screens due to its fuming properties.

-

Titanium is also used in the automotive industry for high-performance vehicles, where its low weight and high strength are beneficial. Titanium components help reduce vehicle weight and improve performance.

-

Titanium and its alloys are also used in hard coatings for tools and industrial equipment, providing wear resistance and durability in demanding applications.

Medical Uses of Titanium

-

Titanium implants, such as hip and knee replacements, are widely used due to their biocompatibility, corrosion resistance, and high strength.

-

Dental implants, including crowns and bridges, are also made from titanium due to its ability to bond with bone and resist corrosion.

-

Titanium’s low density and high strength make it an ideal material for medical devices, such as surgical instruments and implants.

-

The use of titanium in medical applications has improved the quality of life for many patients, providing durable and reliable implants.

-

Titanium’s corrosion resistance and biocompatibility have made it a crucial material in the medical industry.

Fabrication and Machining of Titanium

Metallic titanium is produced industrially by reducing titanium tetrachloride using the Kroll process, as titanium cannot be readily produced by simple reduction methods. The Kroll process involves reducing titanium tetrachloride (TiCl4) with magnesium to obtain high-purity metallic titanium. During chemical processing and refining, different titanium species are encountered, which influence the reactivity and solubility of titanium in various environments.

Titanium can be fabricated using various methods, including welding, forging, and casting. Processing titanium often involves elevated temperatures, which can affect the surface oxide layer, though this layer is typically removed to preserve material properties.

Machining titanium requires specialized equipment and techniques due to its high strength and low thermal conductivity.

The fabrication and machining of titanium are critical steps in producing high-quality components for various industries.

Titanium’s properties, such as its strength and corrosion resistance, can be enhanced through fabrication and machining processes.

The use of titanium in fabrication and machining has improved the performance and durability of various components.

Advantages and Disadvantages of Titanium

-

The advantages of titanium include its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

-

The disadvantages of titanium include its high cost, difficulty in machining, and limited availability.

-

Titanium’s unique properties make it a valuable material for various applications, despite its limitations.

-

The advantages of titanium outweigh its disadvantages in many industries, making it a popular choice for high-performance applications.

-

The use of titanium has improved the performance and durability of various components, despite its limitations.

Titanium Alloys and Their Properties

-

Titanium alloys, such as Ti-6Al-4V, are known for their highest strength among commercially available titanium grades, and exhibit superior corrosion resistance, high tensile strength, and low density.

-

The properties of titanium alloys can be enhanced by alloying with other elements, such as aluminum and vanadium.

-

Titanium alloys are widely used in aerospace, medical, and marine industries due to their unique combination of physical and mechanical properties.

-

The use of titanium alloys has improved the performance and durability of various components.

-

Titanium alloys are a crucial material in modern engineering, providing a favorable balance between weight and strength.

Conclusion

-

Titanium is a versatile material with a unique combination of physical and mechanical properties, making it ideal for various industrial applications.

-

The properties of titanium, including its strength-to-weight ratio, corrosion resistance, and biocompatibility, make it a valuable material for aerospace, medical, and marine industries.

-

The use of titanium has improved the performance and durability of various components, and its unique properties make it a popular choice for high-performance applications.

-

Titanium’s density is a critical factor in its applications, providing a favorable balance between weight and strength.

-

The future of titanium is promising, with ongoing research and development aimed at improving its properties and applications.