Are you struggling to join titanium and stainless steel without causing failures? This common engineering challenge can lead to costly mistakes if you don’t use the right approach.

Directly welding titanium to stainless steel is metallurgically unsound due to the formation of brittle compounds. However, reliable connections are possible using specialized methods like diffusion bonding1, explosion welding, bimetallic transition joints2, or mechanical fasteners with proper insulation to prevent corrosion.

I’ve spent over a decade helping procurement managers like David solve complex material challenges. He often needs to integrate titanium components into existing stainless steel systems for industrial equipment. The question of how to join them comes up constantly. It’s not as simple as picking a welding rod. The physics of these two metals creates issues that can compromise an entire project. But don’t worry, there are clear, proven solutions for creating strong and durable connections. Let’s break down the methods that work and explore the common questions that arise when you bring these two powerful metals together.

How to join titanium and stainless steel?

Do you need to create a permanent joint between titanium and stainless steel? Standard welding methods fail, leaving you with a connection that is weak and will crack under stress.

You must use specialized techniques like diffusion bonding, explosion welding, or brazing. For non-welded connections, mechanical fasteners or pre-fabricated bimetallic transition joints are excellent, reliable solutions that avoid the metallurgical problems of direct fusion welding.

The core problem with trying to fusion weld titanium to stainless steel is chemistry. When they melt and mix, they form brittle intermetallic compounds, specifically iron-titanium (Fe-Ti) and chromium-titanium (Cr-Ti) phases. These compounds act like glass within the weld, making the joint extremely fragile and prone to cracking, even with no load. So, we have to use methods that either avoid melting them together or control the process at an atomic level.

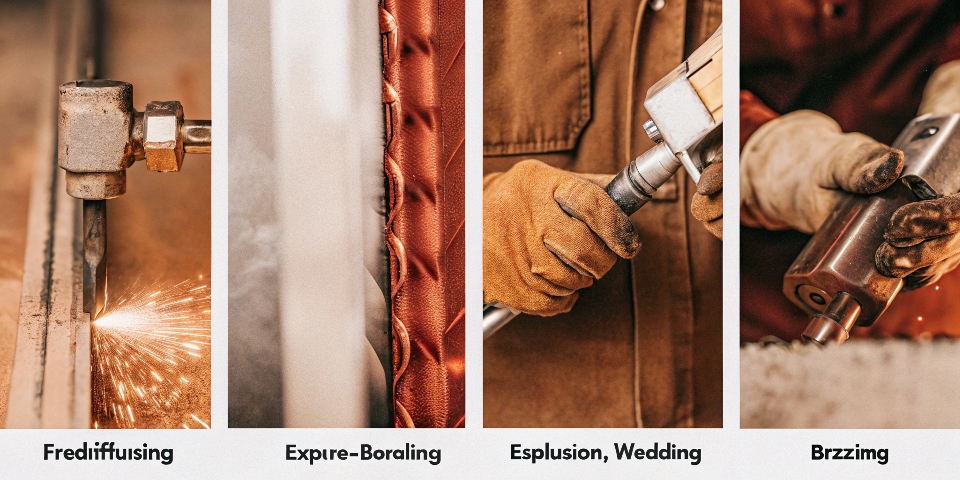

Advanced Welding & Bonding Methods

For the most critical applications, especially in aerospace or high-performance industrial equipment, we turn to advanced techniques. Diffusion bonding involves pressing the two metals together at high temperatures, but below their melting points. Over time, atoms from each metal diffuse across the boundary, creating a solid-state weld that is incredibly strong and clean. Another powerful method is explosion welding. It uses a controlled detonation to slam the two metals together at extreme velocity, creating a metallurgical bond without significant heat. This is how many of the bimetallic transition pieces I source for clients are made. Brazing is another option, where a third filler metal with a lower melting point is used to join the parts without melting the base metals.

Mechanical & Transitional Joining

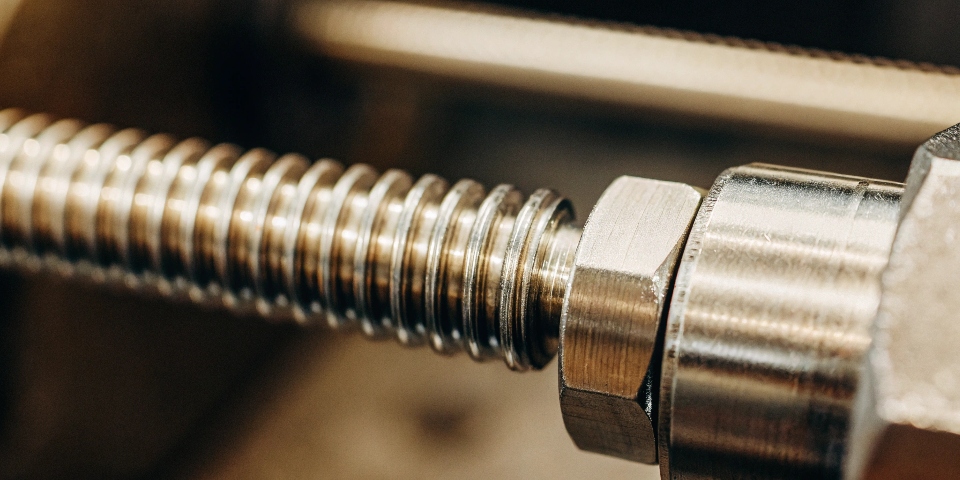

For many industrial applications, a simpler method is better. Using titanium bolts on a stainless steel flange, or vice versa, is a common mechanical solution. The key here is to prevent galvanic corrosion3, which we’ll discuss next. The most practical solution I often recommend to David is a bimetallic transition joint. This is a pre-fabricated part, often a short pipe or plate, where one end is titanium and the other is stainless steel, already bonded using explosion welding. You can then use standard welding techniques to connect titanium-to-titanium and stainless-to-stainless, completely solving the incompatibility issue.

| Joining Method | Best For | Pros | Cons |

|---|---|---|---|

| Diffusion Bonding | Aerospace, high-precision parts | Extremely strong, clean joint | High cost, slow process, size limits |

| Explosion Welding | Large plates, transition joints | High-strength bond for large areas | Requires specialized facilities |

| Brazing | Small components, tubing | Lower temperature, less distortion | Lower strength than welding |

| Mechanical Joints | Non-permanent, accessible assemblies | Simple, reversible, cost-effective | Potential galvanic corrosion risk |

Can you mix titanium and stainless steel?

Are you worried that putting titanium and stainless steel together in one system will cause corrosion? This fear is valid, as combining dissimilar metals can lead to rapid and catastrophic failure.

Yes, you can absolutely mix titanium and stainless steel within a system, but you must electrically isolate them from each other in a corrosive environment. Use non-metallic gaskets, sleeves, or coatings to prevent direct contact and stop galvanic corrosion.

The issue here is called galvanic corrosion. It happens when two different metals are in electrical contact within an electrolyte, like saltwater or even humid air. One metal becomes the anode and corrodes faster, while the other becomes the cathode and is protected. Think of it like a battery where one side sacrifices itself. When I explain this to David for his marine or chemical equipment designs, I emphasize that prevention is simple but essential. The success of a mixed-metal assembly depends entirely on breaking that electrical circuit between the two metals.

Understanding the Galvanic Series

In the galvanic series, titanium is a very noble metal, meaning it is highly resistant to corrosion. Most common stainless steel alloys, like 304 and 316, are less noble. When you connect them directly in seawater, the stainless steel becomes the anode and will corrode at an accelerated rate to protect the titanium. I saw a case early in my career where a boat owner used stainless steel bolts to attach a titanium fitting below the waterline. Within a year, the bolts had corroded so badly they failed. The titanium fitting, however, looked brand new. This is galvanic corrosion in action.

Practical Insulation Methods

The solution is to create an electrical barrier. For flanged pipe connections, a non-metallic gasket made from a material like PTFE or neoprene is perfect. For bolted joints, using non-conductive plastic or nylon washers and sleeves is the standard method. These small, inexpensive parts isolate the bolt from making contact with one of the flanges, breaking the circuit. For surfaces that must be in close proximity, a dielectric coating can be applied to one of the metals. These simple insulation strategies are the key to successfully using titanium and stainless steel together in any corrosive service.

| Insulation Method | How it Works | Common Application |

|---|---|---|

| Non-Metallic Gaskets | Creates a physical and electrical barrier | Flange connections in piping systems |

| Insulating Sleeves/Washers | Isolates fasteners from a metal surface | Bolted assemblies in marine environments |

| Dielectric Coatings | Applies a non-conductive paint or layer | Where direct contact is hard to avoid |

Does titanium gall with stainless steel?

Are you concerned about threaded fasteners made of titanium and stainless steel seizing up? Galling, or cold welding, can destroy expensive components and bring production to a halt.

Titanium has a very low tendency to gall with stainless steel. This is because its hard, slick, and stable oxide layer prevents the metal-on-metal adhesion that causes galling, making it a much safer combination than stainless-on-stainless.

Galling is a nightmare for engineers. It’s a form of severe adhesive wear where two materials, especially under high pressure like in a threaded connection, fuse together. Trying to unscrew a galled bolt can rip the threads right out. The problem is especially bad when you use two pieces of the same metal, or very similar ones. Stainless steel on stainless steel is famous for galling because the surfaces are relatively soft and have a strong chemical attraction to each other. I’ve had many conversations with maintenance teams who dread dealing with seized stainless fasteners.

The Anti-Galling Advantage of Titanium

Titanium behaves differently. The secret is its extremely stable and passive oxide layer (TiO2). This ceramic-like layer forms instantly on the surface of titanium when exposed to air. It is hard, tenacious, and acts as a natural barrier, preventing direct metal-to-metal contact. When a titanium bolt is threaded into a stainless steel nut, this oxide layer functions like a dry lubricant. It reduces the coefficient of friction and dramatically lowers the risk of the two surfaces sticking and tearing. This makes the combination of titanium and stainless steel fasteners a reliable choice for applications where disassembly is required.

Best Practices Still Apply

Even with this natural advantage, I always advise clients to use an anti-seize lubricant4. It’s cheap insurance against any potential issues, especially in high-torque or high-vibration environments. A good quality, metal-free lubricant will fill any microscopic imperfections in the surfaces and provide an extra layer of protection. For David’s team, who assemble and disassemble large industrial rigs, using an anti-seize on all dissimilar metal threads is a non-negotiable part of their standard procedure. It ensures their equipment remains serviceable and avoids costly repairs from galled threads.

Why is titanium added to stainless steel?

Have you ever seen stainless steel grades like 321 or 316Ti and wondered why they contain titanium? This small addition has a massive impact on the material’s performance in specific, demanding environments.

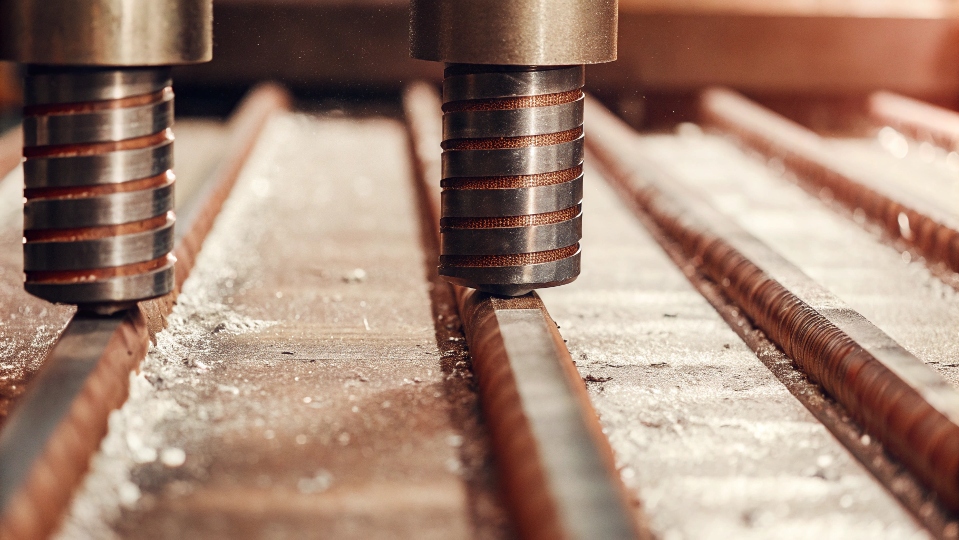

Titanium is added to stainless steel as a "stabilizing" element. It bonds with carbon to form titanium carbides, which prevents the steel from becoming susceptible to intergranular corrosion after being exposed to high temperatures, such as during welding.

To understand why titanium is so important, we first need to look at a problem called "sensitization." It’s a weakness that affects standard austenitic stainless steels like the common 304 grade. When you heat this type of steel—for example, during welding—to a temperature range of 425–870°C (800–1600°F), a damaging reaction happens inside the metal’s structure. This knowledge is critical for anyone specifying materials for high-temperature service, like in exhaust systems or heat exchangers.

The Problem of Sensitization

Inside the steel, carbon has a strong affinity for chromium. In the sensitization temperature range, the carbon atoms migrate to the boundaries between the metal’s crystals (grain boundaries) and combine with chromium to form chromium carbides. This process locks up the chromium, depleting it from the areas near the grain boundaries. Since chromium is the key element that gives stainless steel its corrosion resistance, these depleted zones become highly vulnerable to corrosion. This "intergranular corrosion" can cause the material to fail along the grain boundaries, even if the rest of the metal looks fine.

Titanium as a Carbon Stabilizer

This is where titanium comes in. Titanium has an even stronger affinity for carbon than chromium does. When we add a small amount of titanium to the molten stainless steel (creating grade 321 or 316Ti), it acts as a stabilizer. The titanium preferentially combines with any free carbon in the steel to form titanium carbides (TiC) at very high temperatures. These carbides are stable and distributed harmlessly throughout the metal. This process effectively "locks up" the carbon, so when the steel is later welded or heated, there is no free carbon left to react with the chromium. The chromium remains evenly distributed, and the steel retains its corrosion resistance at the grain boundaries.

| Stainless Steel Grade | Key Feature | Best For | Why It Matters |

|---|---|---|---|

| 304 | General purpose | Kitchen sinks, food processing | Prone to sensitization after welding. |

| 321 (Ti-Stabilized) | High-temp corrosion resistance | Aircraft exhausts, high-temp expansion joints | Titanium prevents weld decay and maintains integrity. |

| 316 | Molybdenum for pitting resistance | Marine hardware, chemical equipment | Excellent resistance to chlorides. |

| 316Ti (Ti-Stabilized) | Pitting resistance + high-temp stability | High-temp chemical processing vessels | Combines the benefits of 316 and 321. |

Conclusion

Connecting titanium and stainless steel requires specific knowledge, but it’s entirely possible. Understanding advanced joining techniques, galvanic corrosion prevention, and the role of alloying makes these materials compatible for demanding applications.

-

Learn about this advanced method that creates strong, clean joints without melting. ↩

-

Find out how these pre-fabricated parts solve compatibility issues between metals. ↩

-

Learn how to protect your metal assemblies from rapid corrosion. ↩

-

Find out how this lubricant can protect threaded connections from seizing. ↩