Struggling to pick between titanium and stainless steel for an exhaust? A wrong move could add weight and compromise performance, hurting your bottom line. I’ll help you decide.

Yes, a titanium exhaust is often better for pure performance. It cuts weight significantly and resists heat extremely well. However, stainless steel provides excellent durability and corrosion resistance at a much lower cost, making it a more practical choice for many drivers and manufacturers.

That quick answer gives you the basics. But as a procurement manager, you need more than just the basics to make a smart investment. David, a client in Germany, often asks me to go deeper on this exact topic. He needs to justify every choice with hard data. Let’s break down the specific questions he asks, so you can have the same confidence in your decision. The best choice depends entirely on your specific goals.

Is stainless steel or titanium better for exhaust?

You need the best material for your exhaust system. But the "best" depends on your budget and performance goals. Choosing incorrectly means wasting money or leaving power on the table.

Titanium is better for racing and high-performance vehicles where every gram matters. Stainless steel is better for daily drivers and budget-conscious builds, offering great longevity and value. The best material depends entirely on the application’s top priority: speed or practicality.

In my work with fabrication shops, the choice always comes down to the project’s main goal. For a motorsport client, every ounce saved on the car is an advantage on the track. For them, we supply Grade 2 or Grade 5 titanium1. It’s not just about weight; it’s about a competitive edge.

Breaking Down the Materials

For someone like David, who manages procurement for industrial equipment but also sources for performance projects, the technical sheet is everything. He needs to see the numbers side-by-side to justify the cost.

Here’s a simple comparison I often share with my clients:

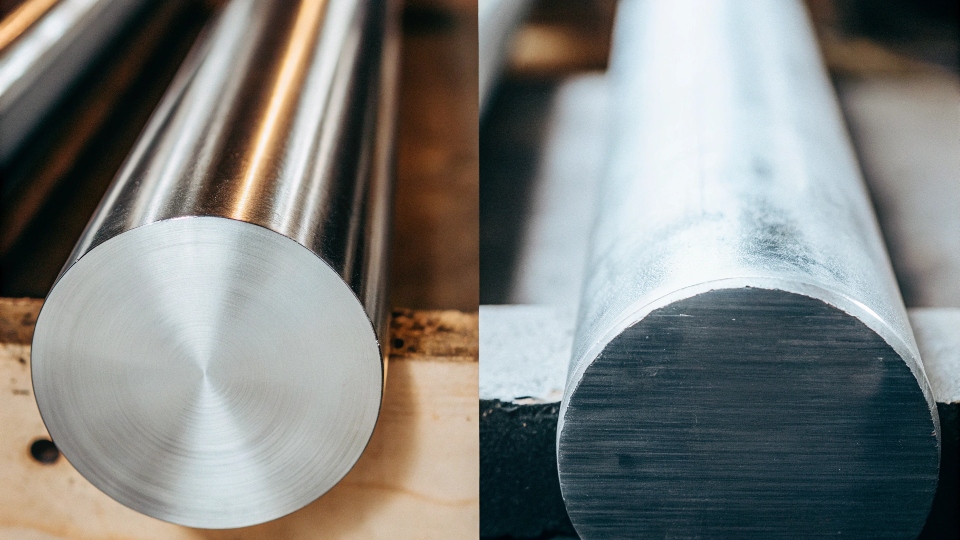

| Feature | Titanium (Grade 2) | Stainless Steel (304) |

|---|---|---|

| Weight | Very Light (4.51 g/cm³) | Heavier (8.0 g/cm³) |

| Corrosion Resistance | Exceptional | Very Good |

| Heat Dissipation | Excellent | Good |

| Cost | High | Moderate |

| Fabrication | More Difficult | Easier |

For most road cars, 304 stainless steel is the practical champion. It resists rust, it’s strong, and it’s affordable. But when a client’s project is all about pushing limits, titanium is the only real answer. The weight savings directly translate to better acceleration and handling.

What are the disadvantages of titanium exhaust2?

You’ve heard the hype about titanium exhausts. Their light weight and performance sound amazing. But what are the hidden costs and practical problems you might face during manufacturing?

The main disadvantages are cost, fabrication complexity, and lower impact resistance. Titanium is much more expensive than steel, requires specialized welding skills and equipment, and can crack under impact more easily than its stainless steel counterpart. It’s a trade-off for its low weight.

Titanium is an amazing metal, but it’s not without its challenges. I remember a client who was developing a new performance exhaust line. They were excited about the weight savings but ran into issues during the prototyping stage. These are the same issues I advise my clients to plan for.

The Cost Factor

The first and most obvious disadvantage is the price. The raw material itself is more expensive than stainless steel. This cost is passed down the line, from us as a supplier to the fabricator, and finally to the end customer. For limited-run or premium vehicles, this is acceptable. For mass-market cars, it’s usually not.

The Fabrication Hurdle

Welding titanium is a specialized skill. You can’t just use standard equipment. It requires an inert gas environment, usually argon, to prevent the metal from becoming contaminated and brittle at high temperatures. This means fabricators need special tools and trained welders, which increases production costs and time.

Durability Concerns

While titanium is strong, it’s also less ductile than steel. This means it can be more prone to cracking from vibrations or a direct impact, like hitting a speed bump too hard. This is why you see it on race cars that are meticulously maintained, and less often on a daily driver that has to endure rough roads.

What is the best metal for exhaust?

With so many options, you just want to know what the best metal is. Picking one without knowing all the facts can lead to a system that fails or doesn’t deliver.

There is no single "best" metal for all exhausts. Titanium is best for ultimate, lightweight performance. 304 stainless steel is best for a balance of durability, cost, and everyday use. The best choice always depends on the vehicle’s purpose and your budget.

When David calls me, he doesn’t ask, "What’s the best?" He asks, "What’s best for this project?" That’s the right way to think about it. The "best" metal is the one that best meets the project’s primary objective. Let’s map this out to make it simple.

A Simple Decision Framework

To find the best material, answer these two questions:

- What is the primary goal? (e.g., maximum weight reduction, cost-effectiveness, long life)

- What is the operating environment? (e.g., racetrack, daily driving, harsh winters with road salt)

Based on your answers, you can use this guide:

| If your primary goal is… | Then the best choice is… | Why? |

|---|---|---|

| Maximum Performance & Weight Savings | Titanium (Grade 2 or 5) | It offers the highest strength-to-weight ratio. Nothing else comes close for shedding pounds. |

| All-Around Value & Durability | Stainless Steel (304) | It provides excellent corrosion resistance and good strength for a reasonable price. This is the workhorse. |

| Basic Budget-Friendly Functionality | Stainless Steel (409) | This is often used in OEM systems3. It’s less corrosion-resistant than 304 but is very inexpensive. |

For 90% of aftermarket and many OEM applications, 304 stainless steel hits the sweet spot. It’s the material I supply most often for general exhaust work. For the elite 10%—supercars, race bikes, and custom builds—titanium is the undisputed king.

Does titanium change the sound of an exhaust?

You know material affects weight and performance. But what about the sound? You want a unique exhaust note, but you’re unsure if titanium actually makes a difference you can hear.

Yes, titanium absolutely changes the sound. Due to its unique density and the ability to use thinner walls, titanium exhausts produce a higher-pitched, more metallic, and often raspier sound compared to the deeper, smoother tone of a stainless steel system.

The sound of an exhaust is a key part of the driving experience for many enthusiasts. I have clients in the high-performance automotive sector who choose titanium as much for the sound as for the weight savings. The acoustic difference is real, and it comes down to simple physics.

The Science of the Sound

Think of a bell. A thick, heavy brass bell has a deep, resonant "dong." A smaller, thinner tin bell has a high-pitched "ting." The same principle applies to exhaust tubing.

- Wall Thickness: Because titanium is so strong, manufacturers can use tubing with much thinner walls than they can with stainless steel. Thinner walls vibrate differently and at a higher frequency, creating a sharper sound.

- Material Density: Titanium and steel have different densities and resonant frequencies. The metal itself vibrates in a unique way as exhaust gases pulse through it. Titanium’s properties lend itself to a crisper, more exotic tone that many associate with racing cars and supercars. Steel, being denser, tends to muffle certain frequencies, resulting in a deeper, more mellow sound.

For a procurement manager like David sourcing for a special project, this is a key selling point. The unique sound of a titanium exhaust is a mark of exclusivity and high performance.

Conclusion

Ultimately, titanium excels for pure, lightweight performance with a distinct sound. For a durable, cost-effective, and practical solution, stainless steel remains the unbeatable all-around choice for most applications.

-

Find out why Grade 5 titanium is favored in high-performance applications and its unique properties. ↩

-

Explore the advantages of titanium exhausts, including weight savings and performance enhancements, to make an informed decision. ↩

-

Learn about the materials used in OEM exhaust systems to understand industry standards and practices. ↩