Are your desalination plant components failing from saltwater corrosion? This constant battle leads to expensive downtime and maintenance. The solution lies in choosing a material built to withstand these harsh conditions.

Titanium tubes are essential for Multi-Stage Flash (MSF)1 desalination plants because of their superior corrosion resistance in hot saltwater. They are used in critical components like condensers and heat exchangers to ensure a long service life, reduce maintenance, and guarantee operational reliability.

Choosing the right material for your industrial project can feel overwhelming. I see procurement managers like David struggle with this all the time. They need to balance cost, performance, and longevity. When it comes to MSF desalination, the choice has massive implications for the plant's efficiency and profitability. You need to understand not just what material to use, but why it works so well. Let's explore the specific reasons why titanium has become the industry standard. This knowledge will help you make sourcing decisions with confidence and secure the best outcome for your operations.

What Specific Roles Do Titanium Tubes Play in an MSF Plant?

Your plant’s performance depends on every component working perfectly. A material failure in a key system causes delays and eats into your budget. So, specifying the right material is critical.

In an MSF plant, titanium tubes are primarily used for the heat exchangers and condensers. Their job is to transfer heat efficiently while resisting constant attack from hot, high-velocity brine and corrosive gases, ensuring the plant operates without interruption for decades.

To really understand why titanium is used here, let's quickly look at the MSF process. The plant heats saltwater (brine) and passes it through a series of chambers, each at a lower pressure than the last. In each stage, a portion of the hot brine "flashes" into steam. This steam then passes over bundles of tubes containing cooler seawater, causing the steam to condense back into fresh, pure water. The tubes doing this condensing work are the heart of the system. They face an incredibly harsh environment: high temperatures, extreme salinity, and constant water flow. Weaker materials would corrode or erode quickly. I've worked with many clients who previously used copper-nickel alloys and had to replace them every few years. Titanium, however, excels in this role, making it the most reliable choice for long-term operations.

| Merkmal | Titan | Kupfer-Nickel (90/10) | 316L Stainless Steel |

|---|---|---|---|

| Max Flow Velocity | Very High (>27 m/s) | Low (~3 m/s) | Moderate (~10 m/s) |

| Pitting Resistance | Ausgezeichnet | Schlecht | Mäßig |

| Service Life in MSF | 30+ Years | 5-10 Years | 10-15 Years |

| Relative Cost | High Initial Cost | Mittel | Mittel |

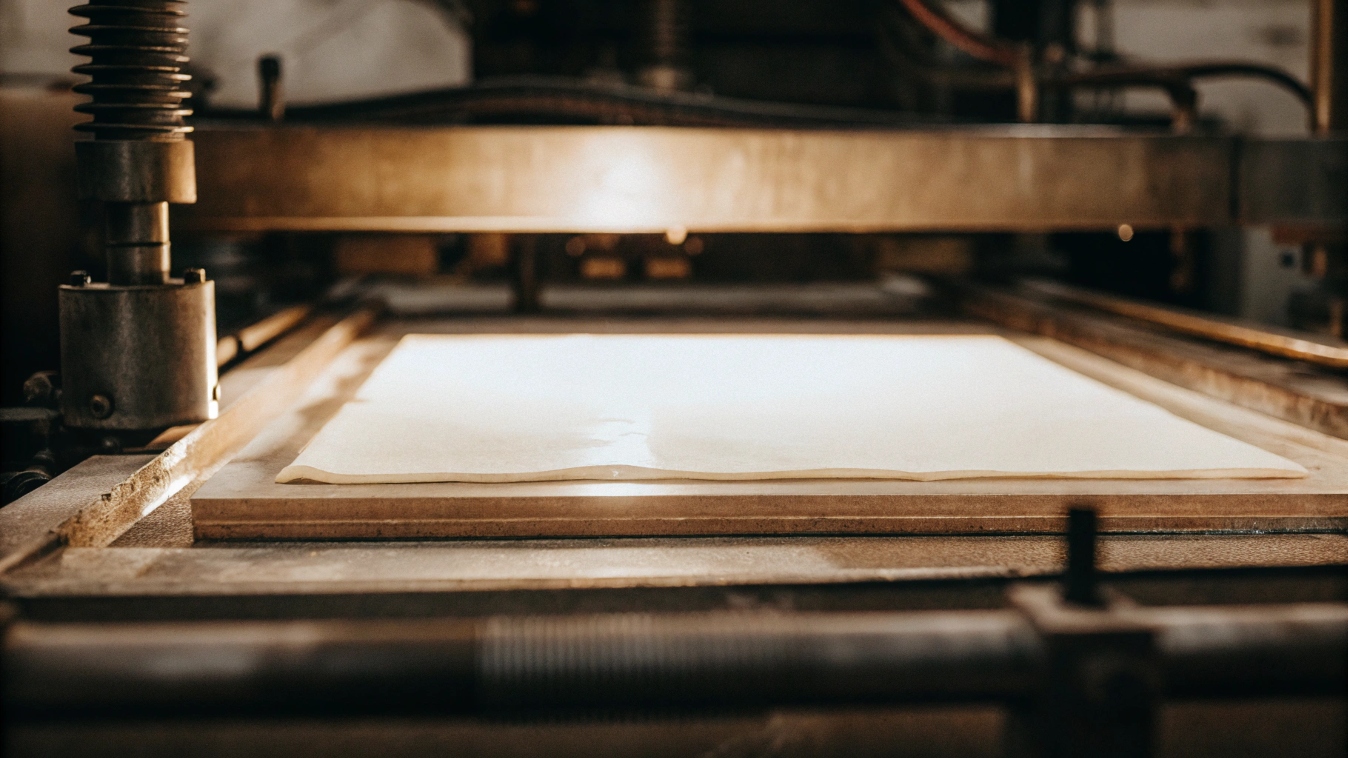

How Is Titanium Tubing Manufactured to Meet These Demanding Conditions?

You need to trust that the materials you source will perform as promised. A poorly made tube, even if it's titanium, can have hidden defects. This creates a huge risk for your project's success.

We manufacture high-quality titanium tubing at our Baoji facility through a strict process. It starts with vacuum melting for purity, followed by precision cold rolling for exact dimensions, and ends with annealing to optimize strength and corrosion resistance, all compliant with ASTM/ASME standards.

For a procurement manager like David, understanding the manufacturing journey provides confidence in the final product. It's not just about getting a tube; it's about getting a tube that won't fail. Our process is designed for reliability.

Key Manufacturing Steps

- Vacuum Arc Remelting (VAR)2: We start by melting titanium sponge and alloys in a vacuum. This removes impurities like hydrogen and oxygen, which could compromise the metal's integrity. The result is a pure, solid ingot, which is the foundation for a high-performance tube.

- Forging & Extrusion: The ingot is then worked into a smaller, more manageable shape called a billet. This billet is heated and pushed through a die to create a thick-walled hollow tube. This step sets the basic shape of the final product.

- Cold Rolling (Pilgering): This is the most critical step for desalination tubes. The tube hollow is processed at room temperature through rollers that reduce its wall thickness and diameter with extreme precision. This creates a very smooth surface, which is vital for efficient heat transfer and preventing biofouling in the plant.

- Annealing: After cold rolling, the tube is heat-treated in a process called annealing. This relieves internal stresses created during manufacturing, restores its ductility (flexibility), and perfects the grain structure for maximum corrosion resistance. Every tube we ship is fully certified to standards like ASTM B338, so you have documented proof of its quality.

Why Is Titanium So Exceptionally Resistant to Saltwater Corrosion?

Saltwater destroys most metals. You've probably seen it yourself on coastal structures or other equipment. This corrosion is a constant threat, causing leaks, contamination, and sudden failures in a desalination plant.

Titanium's incredible resistance comes from a thin, stable, and self-healing layer of titanium dioxide (TiO₂) that forms on its surface instantly. This passive film acts as a powerful, non-reactive barrier, protecting the metal from chloride ions in hot seawater.

This protective layer is what makes titanium so special. You can think of it as a microscopic suit of armor. The moment titanium is exposed to oxygen or moisture—even a tiny amount—this tough, inert oxide layer forms. What's more amazing is that if this layer gets scratched or damaged, it instantly repairs itself. This "self-healing" ability is why titanium doesn't suffer from the localized pitting corrosion that plagues even high-grade stainless steels in saltwater. I recently spoke with a plant manager in Germany who shared that their MSF facility has been using our Grade 2 titanium tubes in their heat exchangers for over 20 years without a single corrosion-related failure. He told me their previous copper-alloy tubes needed repairs every few years. This real-world performance is why leading engineers specify titanium for projects where reliability is non-negotiable.

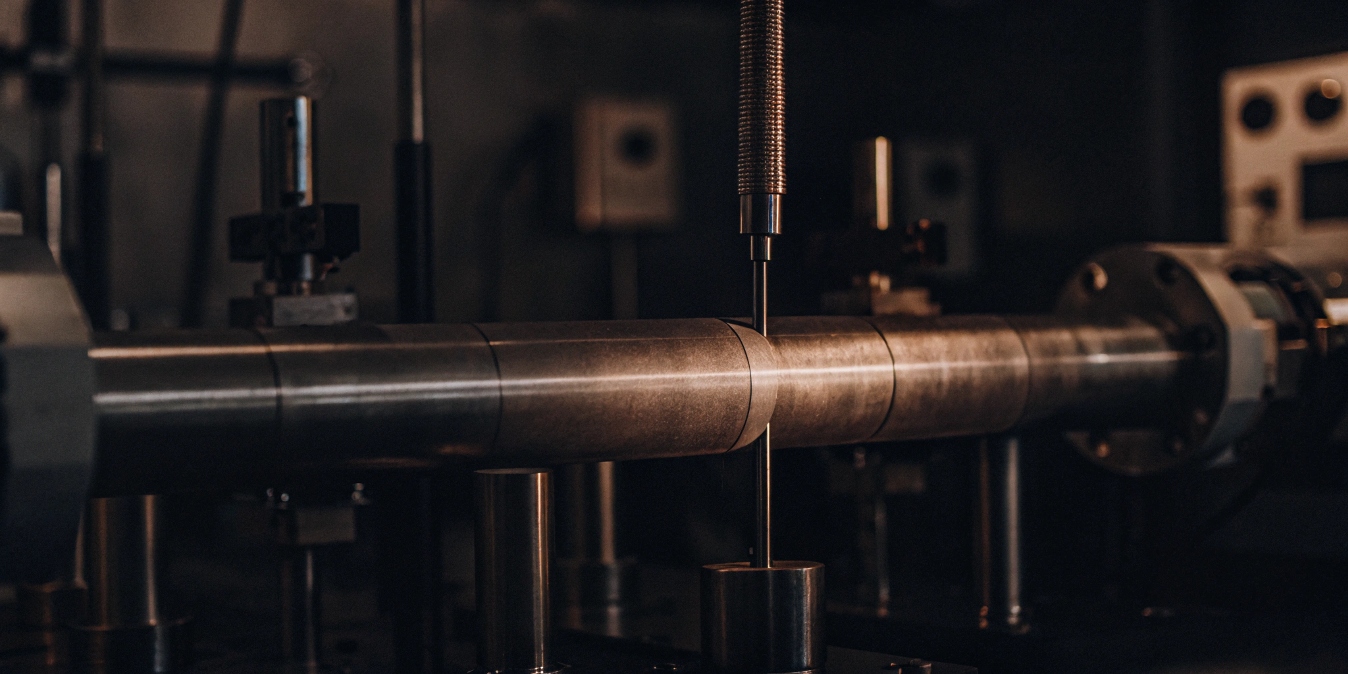

Is Titanium Tubing Strong Enough for High-Pressure MSF Operations?

In an MSF plant, tubes must handle high-pressure steam and water. Corrosion resistance is useless if the material isn't strong enough. A tube failure under pressure is a catastrophic event you cannot afford.

Yes, titanium tubing has excellent strength for MSF applications. Common grades like Grade 2 offer tensile strengths of 345 MPa or more. This is more than enough to withstand the high pressures and temperatures inside the system while remaining ductile for easy fabrication.

For a technical buyer, strength data is crucial. We perform rigorous testing on all our products to guarantee they meet specifications. The tensile strength measures how much pulling force a tube can take before it breaks. The values for titanium are very impressive, especially when you consider its low density. It has one of the highest strength-to-weight ratios of all common metals. This means you get the necessary strength without excessive weight, which can simplify structural support designs.

Understanding Titanium Grades

The choice of grade also matters. While there are many, two are most common in desalination.

- Güteklasse 2 (handelsüblich rein): This is the industry workhorse. It provides the perfect balance of moderate strength, excellent corrosion resistance, and good formability. It's the go-to choice for most MSF heat exchanger and condenser tubes.

- Grade 7 (Palladium Alloy): This grade contains a small amount of palladium. It offers the same strength as Grade 2 but has enhanced corrosion resistance, especially against crevice corrosion in low-pH or reducing conditions. We recommend it for the most aggressive parts of the system where extra protection is needed. Our factory testing confirms that both grades consistently exceed the strength requirements for MSF, giving you peace of mind that the material will perform safely for decades.

Schlussfolgerung

Titanium tubing is the ideal choice for MSF plants. Its unmatched corrosion resistance, proven manufacturing quality, and high strength deliver the long-term reliability and low maintenance costs that your project requires.