Are you choosing between metals and worried about scratches? A damaged surface can ruin a part’s look and function. Understanding their core hardness is the key to your choice.

No, titanium does not scratch easier than aluminum. Based on material hardness scales like Mohs, titanium is significantly harder. This makes it a superior choice for applications where scratch resistance and long-term durability are critical, such as in aerospace or medical devices.

So, the basic answer is clear: titanium is tougher. But this is just the beginning of the story. The real question is why this difference exists and how it should influence your material choice. Let’s look closer at the properties that matter for your business, so you can make an informed decision for your specific application.

Does aluminum scratch easier than titanium?

Considering aluminum for its low cost but worried about damage? Scratched aluminum parts can look cheap and unprofessional, hurting your product’s value. Let’s confirm if its reputation for softness is true.

Yes, aluminum scratches much easier than titanium. As a significantly softer metal, aluminum is more prone to dents, dings, and surface marks from everyday handling and contact. Titanium’s superior hardness provides a clear advantage in preventing these types of surface damage over time.

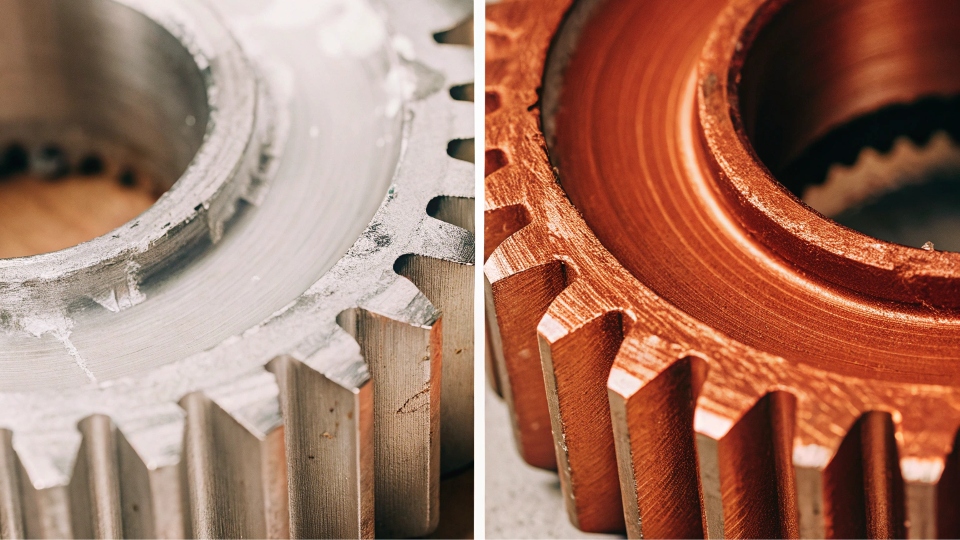

The key difference comes down to material science. We measure a material’s ability to resist scratches using hardness scales like the Mohs scale. On this scale, titanium scores around a 6. In sharp contrast, aluminum only scores about 2.75. This is a massive gap in performance. It means that everyday materials, like a small grain of sand or even a steel tool, can easily leave a deep scratch on an aluminum surface. Titanium, however, will resist these same forces without showing a mark.

Hardness Comparison at a Glance

This simple table helps visualize why this is so important for industrial and commercial applications.

| Material | Mohs Hardness | Easily Scratched By |

|---|---|---|

| Aluminum | 2.5 – 3.0 | A Copper Coin, Hard Plastics |

| Titanium | 6.0 | Hardened Steel File, Quartz |

| Diamond | 10.0 | Another Diamond |

Practical Implications for Distribution

I often discuss this with clients like Ahmed, who runs a metal distribution business in Turkey. He needs to stock materials that won’t get easily damaged in his warehouse or during shipping. For him, stocking aluminum sheets requires extra care in handling and packaging. Titanium, on the other hand, withstands more abuse, which simplifies his logistics and reduces his losses from damaged stock.

Does titanium scratch easily?

You know titanium is strong, but is it completely "scratch-proof"? You cannot afford to invest in a premium material if it still looks worn out after a short time. Let’s clarify its real-world resistance.

No, titanium does not scratch easily compared to most other metals. Its natural hardness prevents marks from the majority of everyday objects. However, it is not completely scratch-proof. Materials that are harder than titanium, like diamond or certain ceramics, can still scratch its surface.

While titanium is very scratch-resistant, it’s important to have realistic expectations. The term "scratch-resistant" is not the same as "scratch-proof." Think of it as a spectrum. Titanium resists scratches much better than aluminum, steel, and even platinum. But a very hard or sharp object, applied with enough force, can still leave a mark. This is why surface treatments are so important in many industries, as they can elevate titanium’s natural durability even further.

Enhancing Surface Hardness

We can make titanium even tougher for demanding environments. For example, in marine engineering, we often supply anodized titanium1 parts. The anodizing process creates an extremely hard layer of titanium oxide on the surface. This layer dramatically increases scratch resistance2 and also adds another barrier against saltwater corrosion. Polishing is another common practice that creates a smoother, more resilient surface.

Common Surface Finishes

| Treatment | Effect on Scratch Resistance | Best For |

|---|---|---|

| Polished | Good | Jewelry, High-End Consumer Goods |

| Anodized | Excellent | Marine, Aerospace, Medical |

| Brushed | Hides Minor Scratches | Architectural, Automotive Trim |

I remember a project supplying a client who was building luxury yacht fittings3. He chose Grade 5 titanium with a specific anodized finish. The choice wasn’t just for corrosion resistance; he needed a finish that would look brand new after years of exposure to ropes, gear, and rough handling.

Which is more durable, titanium or aluminium?

When choosing a metal, durability is everything. A part failure can lead to costly replacements, operational downtime, and even safety risks. Let’s compare the overall durability to see which one truly lasts.

Titanium is significantly more durable than aluminum. Durability is a combination of scratch resistance, strength-to-weight ratio4, and resistance to corrosion and fatigue. Titanium excels in all these areas, making it the superior choice for high-performance and long-lasting applications.

Durability is much more than just surface hardness. It is about how a material performs under constant, long-term stress in its intended environment. This is where titanium establishes its clear superiority over aluminum. It holds up better not just for a week or a month, but for years of demanding use.

Key Factors in Durability

Let’s break down what "durable" truly means for an industrial metal.

- Strength-to-Weight Ratio: Titanium is as strong as many types of steel but is nearly 45% lighter. Aluminum is very light, but it is also much weaker. To get the same level of strength from aluminum, you need a part that is much thicker and heavier overall.

- Fatigue Resistance: This is a material’s ability to endure repeated stress without breaking. Titanium handles vibration and load cycles exceptionally well. Aluminum is far more susceptible to fatigue failure over time.

- Corrosion Resistance: Titanium is almost completely immune to corrosion from saltwater, most acids, and industrial chemicals. Aluminum will corrode, especially in harsh or marine environments.

My experience exporting to the European automotive sector highlights this. We supply titanium for performance exhaust systems, valves, and connecting rods. It can handle the extreme heat and constant vibrations that would cause aluminum parts to warp, crack, and fail in a very short time. In these applications, durability means reliability and safety.

Does a titanium ring scratch easily?

Are you looking at a titanium ring but worry it will get scuffed from daily wear? Nobody wants their favorite piece of jewelry to look old and damaged. Let’s see how it really performs on your hand.

A titanium ring does not scratch easily, especially when compared to traditional rings made of gold, silver, or platinum. Its natural hardness protects it from most daily bumps and scrapes. While not impossible to scratch, it maintains its appearance far better than softer precious metals.

This is a common question I receive, even from my industrial clients who are curious for personal reasons. The answer is best understood by comparing titanium directly to traditional jewelry metals, which are often much softer than people realize.

Titanium vs. Traditional Ring Metals

Gold and platinum are surprisingly soft metals. They scratch, bend, and dent very easily with normal wear. This is why many wedding bands quickly develop a "patina," which is really just a collection of thousands of tiny scratches. Titanium provides a much more robust alternative for daily use.

| Metal | Hardness (Mohs) | Scratch Resistance |

|---|---|---|

| Gold (14k) | ~3.0 | Low |

| Platinum | ~3.5 | Low-Medium |

| Titanium | 6.0 | High |

Choosing the Right Finish for a Ring

A titanium ring will easily resist scratches from keys in your pocket, doorknobs, and desk surfaces. However, scraping it against a very hard surface like a brick wall or a rough rock could still leave a mark. The finish you choose also plays a role. A highly polished titanium ring will show fine scratches more obviously than a ring with a brushed or matte finish. The brushed finish is excellent at hiding minor scuffs, which is why it is an extremely popular choice for men’s rings. It offers the perfect blend of modern style and practical, everyday durability.

Conclusion

Titanium is clearly harder, more durable, and more scratch-resistant than aluminum. This makes it the superior choice for any application where long-term performance and appearance are essential.

-

Discover the advantages of anodized titanium for enhancing durability and appearance. ↩

-

Understand the importance of scratch resistance in selecting materials for different applications. ↩

-

Discover the materials that enhance both performance and aesthetics in luxury yacht design. ↩

-

Understand how the strength-to-weight ratio influences the choice of materials in engineering. ↩