¿Le preocupa el riesgo de incendio del titanio en aplicaciones de alta temperatura? Ha oído que es resistente, pero su comportamiento en condiciones de calor extremo es un grave problema de seguridad y rendimiento.

Sí, el titanio puede arder, pero sólo en determinadas condiciones. Es muy reactivo con el oxígeno a altas temperaturas. Este es un factor crítico para los ingenieros de las industrias aeroespacial y química, pero no suele ser una preocupación para los productos de consumo cotidiano.

Entender cuándo y cómo se quema el titanio es clave para utilizarlo con seguridad y eficacia. Lo he visto de primera mano en mi trabajo aquí, en el Valle del Titanio de Baoji. Veamos más de cerca los detalles. Le ayudará, como a mi clienta Lisa, a tomar mejores decisiones sobre materiales para sus proyectos. Hay que conocer los detalles para evitar errores costosos.

¿Por qué arde el titanio?

¿Cree que el titanio es indestructible? Esta creencia tan extendida puede dar lugar a peligrosos fallos de diseño cuando se trata de altas temperaturas. Hay que conocer su reactividad química.

El titanio arde porque es un metal muy reactivo. A altas temperaturas, reacciona agresivamente con el oxígeno en un proceso llamado oxidación. Esta reacción libera mucho calor, que puede mantener un incendio, sobre todo si el titanio está en forma de polvo fino o virutas finas.

A temperatura ambiente, el titanio está protegido por una capa muy fina y estable de dióxido de titanio1. Esta capa de pasivación se forma casi instantáneamente cuando el titanio se expone al aire. Es la razón por la que el titanio es tan increíblemente resistente a la corrosión. Pero cuando se aplica suficiente calor, este escudo protector se rompe. El titanio metálico subyacente está muy ansioso por reaccionar con el oxígeno. Se trata de una reacción fuertemente exotérmica, lo que significa que libera mucha energía en forma de calor. Si hay suficiente calor para iniciar la reacción y suficiente oxígeno para mantenerla, el titanio arderá. La forma del titanio también es muy importante. Un bloque grande y sólido de titanio es mucho más difícil de inflamar que el polvo fino o las virutas del mecanizado.

El papel del oxígeno y la superficie

En mi trabajo en proyectos aeroespaciales, esta es una preocupación importante. Piense en un componente de un motor a reacción que gira a gran velocidad. Se calienta mucho. Si una pieza de titanio falla, la fricción que se produce al rozar con otra pieza puede generar calor suficiente para inflamar pequeñas partículas de titanio. Esto puede provocar lo que se denomina un "incendio de titanio", que es extremadamente caliente y difícil de extinguir. Diseñamos estas piezas y recomendamos aleaciones y revestimientos específicos para evitarlo. Esto demuestra por qué no basta con fijarse en las propiedades estándar de un material, sino que hay que tener en cuenta el entorno de funcionamiento más desfavorable.

¿Se quema el titanio durante la incineración?

Es posible que tenga un implante médico de titanio. ¿Qué ocurre con él durante la incineración? Es una pregunta frecuente y la respuesta podría sorprenderle.

No, el titanio no arde completamente durante la cremación. Las temperaturas de un cremador, que suelen ser de 800-1.000 °C, no son lo bastante elevadas como para inflamar una pieza sólida de titanio. El implante permanecerá como fragmentos metálicos reconocibles, aunque descoloridos, que se recuperan de las cenizas.

Los hornos crematorios funcionan a temperaturas de entre 800 °C y 1.000 °C (de 1.472 °F a 1.832 °F). Aunque se trata de temperaturas extremadamente elevadas, están por debajo de la temperatura de autoignición de una pieza sólida de titanio, que ronda los 1.200°C. Además, el punto de fusión de la aleación de titanio más común en medicina, el Ti-6Al-4V, es incluso superior, en torno a los 1.660 °C (3.020 °F). Por tanto, un implante sólido y grueso, como una prótesis de cadera o rodilla, no arderá ni se fundirá. Suministramos titanio para estos implantes, y su increíble durabilidad es precisamente la razón por la que se utilizan.

¿Qué ocurre realmente con los implantes?

¿Qué ocurre entonces? El calor intenso hace que la superficie del implante se oxide en gran medida, creando una capa de óxido más gruesa y coloreada. Es posible que vea colores azules, morados o grises en el implante después del proceso, pero el implante en sí permanece estructuralmente intacto. Una vez finalizada la cremación, estas partes metálicas se separan de los fragmentos óseos. Es práctica habitual que los crematorios clasifiquen estos materiales. A menudo, la familia puede solicitar la devolución del implante. Conozco a un jefe de producto en Estados Unidos a cuyo abuelo le pusieron una prótesis de cadera de titanio. A la familia le devolvieron el implante, que estaba un poco descolorido, pero por lo demás tenía exactamente el mismo aspecto que antes. Es una prueba fehaciente de la resistencia del material.

¿Cuál es el inconveniente del titanio?

¿Es el titanio el material perfecto? Se ve en productos de gama alta, pero rara vez se habla de sus inconvenientes. Estos problemas ocultos pueden echar por tierra su presupuesto y sus plazos de producción.

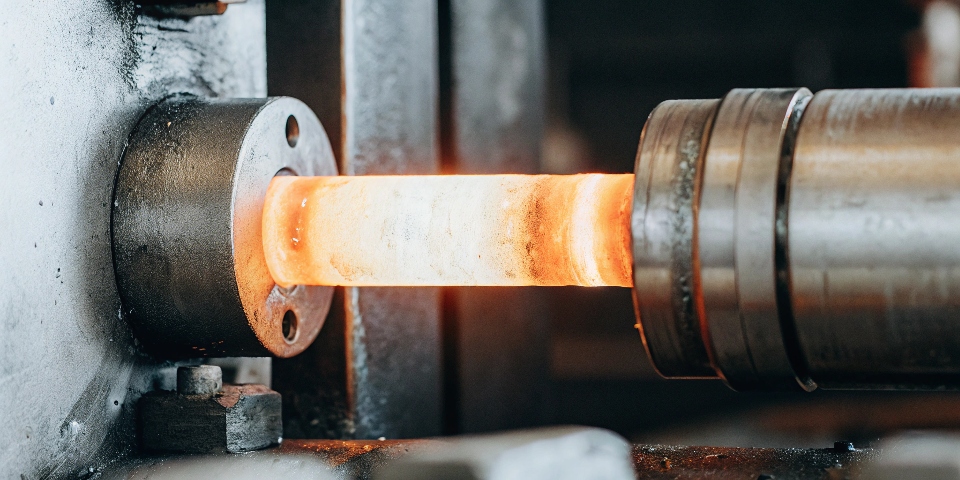

Los mayores inconvenientes del titanio son su elevado coste y la dificultad de mecanizarlo. Extraer y procesar el titanio es un proceso caro y que consume mucha energía. Su dureza y bajo conductividad térmica2 también dificultan el corte y la conformación, aumentando el tiempo de fabricación y el desgaste de las herramientas.

El titanio no es un elemento raro en la corteza terrestre, pero es muy difícil refinarlo hasta convertirlo en un metal puro y utilizable. El proceso principal, la Proceso Kroll3es multietapa, lento y requiere mucha energía. Esta es la razón principal de su elevado coste material en comparación con el acero o el aluminio. Más allá del coste inicial, trabajar con titanio presenta sus propios retos. Es un tema de conversación frecuente que tengo con clientes internacionales como Lisa, que deben equilibrar el rendimiento con los presupuestos de fabricación.

El reto del coste y el mecanizado

El mecanizado del titanio es complicado porque tiene una baja conductividad térmica. Esto significa que, al cortarlo, el calor generado por la fricción no se propaga por el bloque metálico. En su lugar, se concentra justo en la punta de la herramienta de corte. Este intenso calor desgasta rápidamente las herramientas e incluso puede llegar a destruirlas, lo que añade costes y tiempo significativos a la producción. Los operarios tienen que utilizar velocidades de corte bajas, avances altos y grandes cantidades de refrigerante a alta presión para controlar el calor. Para un proyecto con uno de nuestros clientes europeos que fabrica recipientes para productos químicos, tuvimos que presupuestar un 30% adicional para la fabricación en comparación con una pieza similar fabricada en acero inoxidable, sólo para tener en cuenta los requisitos de mecanizado especializado.

| Característica | Titanio (Ti-6Al-4V) | Acero inoxidable (316L) | Aluminio (6061) |

|---|---|---|---|

| Coste relativo | Muy alta | Medio | Bajo |

| Fuerza-peso | Excelente | Bien | Muy buena |

| Resistencia a la corrosión | Excelente | Muy buena | Bien |

| Maquinabilidad | Pobre | Feria | Excelente |

¿A qué temperatura se inflama el titanio?

Necesita conocer el punto exacto de fallo de sus materiales. En el caso del titanio, la temperatura de ignición es una cifra de seguridad crítica. Equivocarse puede provocar un fallo catastrófico.

Una pieza sólida de titanio suele autoinflamarse en torno a los 1.200 °C (2.200 °F). Sin embargo, el polvo o el polvo fino de titanio pueden inflamarse a temperaturas mucho más bajas. El material también empieza a oxidarse rápidamente y a perder resistencia muy por debajo de esa temperatura, a partir de unos 600°C (1.100°F).

Es importante entender la diferencia entre oxidación, ignición y fusión. No son lo mismo. Para una pieza sólida de titanio comercialmente puro, estas son las temperaturas clave que debe conocer.

Oxidación vs. Ignición

La oxidación es una reacción superficial que se produce incluso a temperatura ambiente, pero que se acelera significativamente por encima de los 600 ºC. Este proceso forma una capa frágil y rica en oxígeno denominada "caja alfa" en la superficie del metal, que puede comprometer las propiedades mecánicas de una pieza. La ignición es diferente; es una reacción química autosostenida, un incendio. Para que esto ocurra con una pieza sólida de titanio, es necesario alcanzar unos 1.200°C en un entorno rico en oxígeno. Por último, el punto de fusión es aún más alto, en torno a los 1.670°C.

| Estado / Proceso | Temperatura (aproximada) | Descripción |

|---|---|---|

| Oxidación rápida | > 600°C (1.100°F) | Forma caja alfa quebradiza, debilita el material. |

| Autoencendido (Sólido) | ~1.200°C (2.200°F) | El fuego autosostenido comienza en el oxígeno. |

| Punto de fusión | ~1.670°C (3.040°F) | El material pasa de sólido a líquido. |

Seguridad en la práctica

En mi planta, nos enfrentamos diariamente a estas temperaturas. Cuando fundimos lingotes de titanio en un horno de refusión por arco en vacío (VAR), las temperaturas son muy superiores al punto de fusión. Para evitar un incendio masivo de titanio, debemos eliminar por completo el oxígeno. Primero hacemos un fuerte vacío en el horno y luego lo rellenamos con argón, un gas inerte. El argón expulsa cualquier resto de oxígeno, creando un entorno en el que el titanio simplemente no puede arder, ni siquiera cuando está fundido. Este es un paso de seguridad crítico que nunca podemos saltarnos.

Conclusión

El titanio puede arder, pero su elevado punto de ignición y su necesidad específica de oxígeno lo hacen muy seguro para la mayoría de los usos. Comprender sus límites es la clave del éxito en ingeniería.

-

Descubra cómo actúa el dióxido de titanio como capa protectora y su importancia en la prevención de la corrosión. ↩

-

Comprender la conductividad térmica es crucial para unas prácticas de mecanizado y una selección de herramientas eficaces. ↩

-

Conozca el proceso Kroll y por qué contribuye al elevado coste del titanio. ↩