Are you worried about titanium's fire risk in high-heat applications? You've heard it's strong, but its behavior under extreme heat is a serious safety and performance concern.

Yes, titanium can burn, but only under specific conditions. It is highly reactive with oxygen at high temperatures. This is a critical factor for engineers in aerospace and chemical industries, but not usually a concern for everyday consumer products.

Understanding when and how titanium burns is key to using it safely and effectively. I've seen this firsthand in my work here in Baoji's Titanium Valley. Let's look closer at the details. It will help you, like my client Lisa, make better material decisions for your projects. You need to know the specifics to avoid costly mistakes.

Why does titanium burn?

Do you think of titanium as indestructible? This common belief can lead to dangerous design flaws when high temperatures are involved. You need to understand its chemical reactivity.

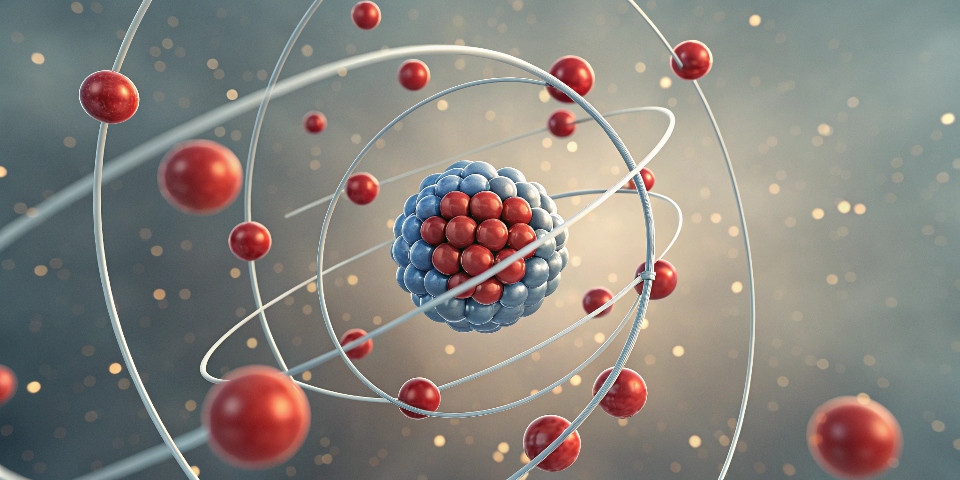

Titanium burns because it is a highly reactive metal. At high temperatures, it reacts aggressively with oxygen in a process called oxidation. This reaction releases a lot of heat, which can sustain a fire, especially if the titanium is in a fine powder or thin shaving form.

At room temperature, titanium is protected by a very thin, stable layer of titanium dioxide1. This passivation layer forms almost instantly when titanium is exposed to air. It's the reason titanium is so incredibly corrosion-resistant. But when you apply enough heat, this protective shield breaks down. The titanium metal underneath is very eager to react with oxygen. This is a strong exothermic reaction, meaning it releases a lot of energy as heat. If there is enough heat to start the reaction and enough oxygen to sustain it, the titanium will burn. The form of the titanium also matters a lot. A large, solid block of titanium is much harder to ignite than fine powder or shavings from machining.

The Role of Oxygen and Surface Area

In my work on aerospace projects, this is a major concern. Think about a jet engine component spinning at high speed. It gets very hot. If a titanium part fails, the friction from scraping against another part can create enough heat to ignite small particles of titanium. This can lead to what is called a "titanium fire," which is extremely hot and difficult to extinguish. We design these parts and recommend specific alloys and coatings to prevent this. It shows why you cannot just look at a material's standard properties; you have to consider the worst-case operating environment.

Does titanium burn during cremation?

You might have a medical implant made of titanium. What happens to it during cremation? This is a common question and the answer might surprise you.

No, titanium does not fully burn during cremation. The temperatures in a cremator, typically 800-1000°C, are not high enough to ignite a solid piece of titanium. The implant will remain behind as recognizable, though discolored, metallic fragments that are recovered from the ashes.

Cremation chambers operate at temperatures between 800°C and 1,000°C (1,472°F to 1,832°F). While this is extremely hot, it is below the auto-ignition temperature of a solid piece of titanium, which is around 1,200°C. Also, the melting point of the most common medical titanium alloy, Ti-6Al-4V, is even higher, at around 1,660°C (3,020°F). So, a solid, thick implant like a hip or knee replacement will not burn or melt. We supply titanium for these implants, and their incredible durability is precisely why they are used.

What Actually Happens to Implants?

So what does happen? The intense heat causes the surface of the implant to oxidize heavily, creating a thicker, colored oxide layer. You might see blue, purple, or gray colors on the implant after the process, but the implant itself remains structurally intact. After the cremation is complete, these metal parts are separated from the bone fragments. It is standard practice for crematoriums to sort these materials. A family can often request to have the implant returned. I know a product manager in the US whose grandfather had a titanium hip replacement. The family was given the implant back, and it was a bit discolored but otherwise looked exactly like it did before. This is a powerful demonstration of the material's resilience.

What is the downside of titanium?

Is titanium the perfect material? You see it in high-end products, but its drawbacks are rarely discussed. These hidden issues can wreck your budget and production timeline.

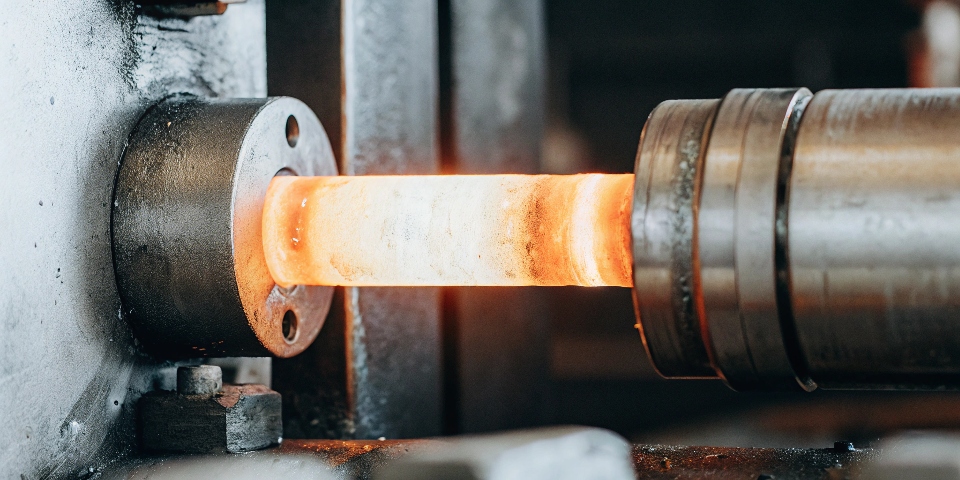

The biggest downsides of titanium are its high cost and the difficulty of machining it. Extracting and processing titanium is an expensive, energy-intensive process. Its hardness and low thermal conductivity2 also make it tough to cut and shape, increasing manufacturing time and tool wear.

Titanium is not a rare element in the earth's crust, but it is very difficult to refine into a pure, usable metal. The main process, the Proceso Kroll3, is multi-staged, slow, and requires a lot of energy. This is the primary reason for its high material cost compared to steel or aluminum. Beyond the initial cost, working with titanium presents its own challenges. This is a frequent topic of conversation I have with international clients like Lisa, who must balance performance with manufacturing budgets.

The Cost and Machining Challenge

Machining titanium is tricky because it has low thermal conductivity. This means that when you cut it, the heat generated by the friction doesn't spread into the metal block. Instead, it concentrates right at the cutting tool's tip. This intense heat quickly wears down and can even destroy the tools, which adds significant cost and time to production. Machinists need to use low cutting speeds, high feed rates, and large amounts of high-pressure coolant to manage the heat. For a project with one of our European clients making chemical vessels, we had to budget an extra 30% for manufacturing compared to a similar part made from stainless steel, just to account for the specialized machining requirements.

| Característica | Titanium (Ti-6Al-4V) | Acero inoxidable (316L) | Aluminum (6061) |

|---|---|---|---|

| Coste relativo | Muy alta | Medio | Bajo |

| Strength-to-Weight | Excelente | Bien | Muy buena |

| Resistencia a la corrosión | Excelente | Muy buena | Bien |

| Machinability | Pobre | Fair | Excelente |

What temperature does titanium ignite?

You need to know the exact failure point of your materials. For titanium, the ignition temperature is a critical safety number. Getting this wrong can lead to catastrophic failure.

A solid piece of titanium typically auto-ignites around 1,200°C (2,200°F). However, fine titanium powder or dust can ignite at much lower temperatures. The material also begins to oxidize rapidly and lose strength well below that, starting around 600°C (1,100°F).

It's important to understand the difference between oxidation, ignition, and melting. They are not the same thing. For a solid piece of commercially pure titanium, these are the key temperatures you need to know.

Oxidation vs. Ignition

Oxidation is a surface reaction that happens even at room temperature but accelerates significantly above 600°C. This process forms a brittle, oxygen-rich layer called "alpha case" on the metal's surface, which can compromise the mechanical properties of a part. Ignition is different; it's a self-sustaining chemical reaction, a fire. For this to happen with a solid piece of titanium, you need to reach about 1,200°C in an oxygen-rich environment. Finally, the melting point is even higher, around 1,670°C.

| State / Process | Temperature (Approximate) | Descripción |

|---|---|---|

| Rapid Oxidation | > 600°C (1,100°F) | Forms brittle alpha case, weakens material. |

| Auto-Ignition (Solid) | ~1,200°C (2,200°F) | Self-sustaining fire begins in oxygen. |

| Melting Point | ~1,670°C (3,040°F) | The material turns from solid to liquid. |

Safety in Practice

In my plant, we deal with these temperatures daily. When we are melting titanium ingots in a vacuum arc remelting (VAR) furnace, the temperatures are well above the melting point. To prevent a massive titanium fire, we must completely remove all oxygen. We first pull a strong vacuum in the furnace and then backfill it with argon, an inert gas. The argon pushes out any remaining oxygen, creating an environment where the titanium simply cannot burn, even when it's molten. This is a critical safety step we can never skip.

Conclusión

Titanium can burn, but its high ignition point and specific need for oxygen make it very safe for most uses. Understanding its limits is the key to engineering success.