¿Confuso a la hora de mezclar titanio y níquel para sus piezas? Esta incertidumbre puede frenar los proyectos. Permítame mostrarle esta aleación única y lo que puede hacer por usted.

Sí, existe una aleación de titanio y níquel llamada Nitinol (NiTi). Se trata de una aleación especial con memoria de forma que puede recuperar su forma original después de doblarse. Esta propiedad superelástica única la hace vital para dispositivos médicos avanzados y piezas aeroespaciales, cumpliendo normas como la ASTM F2063.

Así pues, hemos confirmado que esta aleación es real y muy útil. Pero, ¿qué es exactamente y en qué se diferencia de las aleaciones de titanio habituales? A menudo recibo preguntas como ésta de jefes de producto como Lisa. Ella necesita respuestas claras y sencillas para tomar la decisión correcta para su equipo. Vamos a desglosarlo un poco más para que pueda hablar con confianza sobre estos materiales avanzados con su equipo y sus clientes.

¿Qué es una aleación de níquel y titanio?

¿Necesita un material flexible y resistente para un nuevo producto? Los metales básicos se doblan y se quedan doblados, lo que no es suficiente para los dispositivos inteligentes. La aleación de níquel y titanio, o Nitinol, ofrece superelasticidad, una propiedad revolucionaria para sus diseños.

La aleación de níquel y titanio, o Nitinol, es un material inteligente. Es conocido por dos propiedades especiales: memoria de forma y superelasticidad. Esto significa que puede recordar una forma preestablecida y volver a ella cuando se calienta, o doblarse mucho y recuperarla sin sufrir daños permanentes.

El nitinol es más que una simple mezcla de dos metales: es un compuesto intermetálico. Esto significa que los átomos de titanio y níquel se organizan en una estructura cristalina muy específica. Esta estructura es la que confiere al Nitinol sus capacidades "inteligentes". Puede existir en dos fases diferentes, o formas cristalinas, dependiendo de la temperatura y la tensión que se le aplique. Recuerdo la primera vez que vi un alambre de nitinol en el laboratorio. Lo enfriamos, lo hicimos una bola y lo dejamos caer en agua caliente. Al instante volvió a encajar en una línea recta perfecta. Es un espectáculo impresionante y demuestra por qué se le llama material inteligente. Este comportamiento se rige por normas estrictas como la ASTM F2063, especialmente para piezas médicas.

Comprender las dos propiedades clave

Las dos propiedades principales, la memoria de forma y la superelasticidad, proceden de la capacidad de la aleación para alternar entre sus dos fases.

| Propiedad | Disparador | Resultado | Ejemplo común |

|---|---|---|---|

| Memoria de forma | Calor | El material recupera una forma preestablecida tras ser deformado a una temperatura inferior. | Un stent calentado por el calor corporal para abrir una arteria. |

| Superelasticidad | Tensión (flexión/estiramiento) | El material puede doblarse considerablemente (como el caucho) y luego volver a su forma original. | Monturas de gafas flexibles que sobreviven a la flexión. |

¿Hay níquel en la aleación de titanio?

Está especificando una aleación de titanio para un proyecto, pero le preocupan los elementos inesperados. Añadir un elemento incorrecto puede arruinar la resistencia a la corrosión o la solidez, provocando fallos importantes en el futuro. Aclaremos cuándo hay níquel en las aleaciones de titanio y cuándo no.

Las aleaciones de titanio estándar, como el titanio puro de grado 2 o el de grado 5 (Ti-6Al-4V), no contienen níquel. El níquel sólo es un elemento primario en aleaciones inteligentes específicas como el Nitinol (NiTi). Confundir ambos puede dar lugar a graves errores en la selección de materiales.

Este es un punto crítico que puede causar mucha confusión a los jefes de producto. La gran mayoría de las aleaciones de titanio utilizadas en aplicaciones industriales, como las que producimos aquí en Baoji para equipos de procesamiento químico, no tienen níquel. De hecho, para estas aplicaciones, el níquel se considera una impureza que controlamos cuidadosamente para mantenerla en niveles muy bajos. En mi planta producimos miles de toneladas de titanio puro y aleaciones de titanio y paladio. Nuestro equipo de control de calidad prueba cada lote para asegurarse de que no haya elementos no deseados como el níquel. El nitinol es completamente diferente. El níquel no es una impureza, sino un componente básico que constituye aproximadamente la mitad del material. Es esencial para crear la estructura cristalina única que permite la memoria de forma y la superelasticidad.

Comparación entre el titanio estándar y el níquel-titanio

Permítanme mostrarles una sencilla tabla para que quede clara la diferencia.

| Material | Composición clave | Característica principal | Uso común |

|---|---|---|---|

| Titanio Grado 2 | 99%+ Titanio | Excelente resistencia a la corrosión | Tuberías químicas, intercambiadores de calor |

| Titanio Grado 5 | Ti, ~6% Aluminio, ~4% Vanadio | Elevada relación resistencia/peso | Bastidores aeroespaciales, pernos |

| Nitinol (NiTi) | ~55% Níquel, ~45% Titanio | Memoria de forma y superelasticidad | Stents médicos, Actuadores |

¿Dónde se utiliza el níquel-titanio?

Tienes un material inteligente increíble, pero ¿dónde puedes utilizarlo realmente? Sin ejemplos claros de aplicación, no es más que una curiosidad de laboratorio, no una solución real para su negocio. Exploremos los sectores clave en los que la aleación de níquel y titanio ya está teniendo un gran impacto.

La aleación de níquel-titanio se utiliza principalmente en dos campos de alta tecnología: los dispositivos médicos y los sistemas aeroespaciales. En medicina, se utiliza para stents autoexpandibles, alambres de ortodoncia flexibles y armazones de válvulas cardíacas. En el aeroespacial, para actuadores que despliegan paneles solares.

Las propiedades del nitinol lo hacen perfecto para aplicaciones en las que se necesita precisión, fiabilidad y un movimiento único. En el campo médico, su uso cambia vidas. Por ejemplo, un stent es un diminuto tubo de malla que se utiliza para abrir una arteria obstruida. Un stent de nitinol puede enfriarse y comprimirse en un tubo muy fino, guiarse por el cuerpo y, cuando llega a la arteria, el calor natural del cuerpo lo calienta. Esto hace que se expanda de nuevo a su forma original, más grande, empujando la arteria para abrirla. Tiene que ser biocompatible y lo bastante resistente para soportar millones de latidos a lo largo de la vida de un paciente. La norma ISO 5832-3 contempla específicamente este material para implantes quirúrgicos. Aunque en mis instalaciones no producimos NiTi, seguimos de cerca su evolución porque la precisión que requiere es increíble.

Principales ámbitos de aplicación

Los usos del nitinol van más allá de uno o dos productos. Aquí tiene un desglose de dónde lo encontrará.

| Industria | Ejemplos de aplicación | Por qué se utiliza el nitinol |

|---|---|---|

| Médico | Stents, aparatos de ortodoncia, instrumentos quirúrgicos, armazones de válvulas cardíacas | Biocompatible, superelástico para la flexibilidad, con memoria de forma para el despliegue |

| Aeroespacial | Actuadores (para liberar pestillos), acoplamientos de tubos de fluido | Más ligero que los motores, alta fiabilidad, mecanismo sencillo |

| Bienes de consumo | Monturas de gafas flexibles, aros de sujetador, antenas de teléfono | Puede doblarse mucho y recuperar su forma, lo que aumenta su durabilidad |

¿Cuál es el porcentaje de aleación de níquel y titanio?

Es necesario especificar la composición exacta de un pedido de material. Equivocarse en los porcentajes, aunque sea por muy poco, puede hacer que el material no funcione como usted espera y provocar retrasos o fallos costosos. Veamos la composición química exacta.

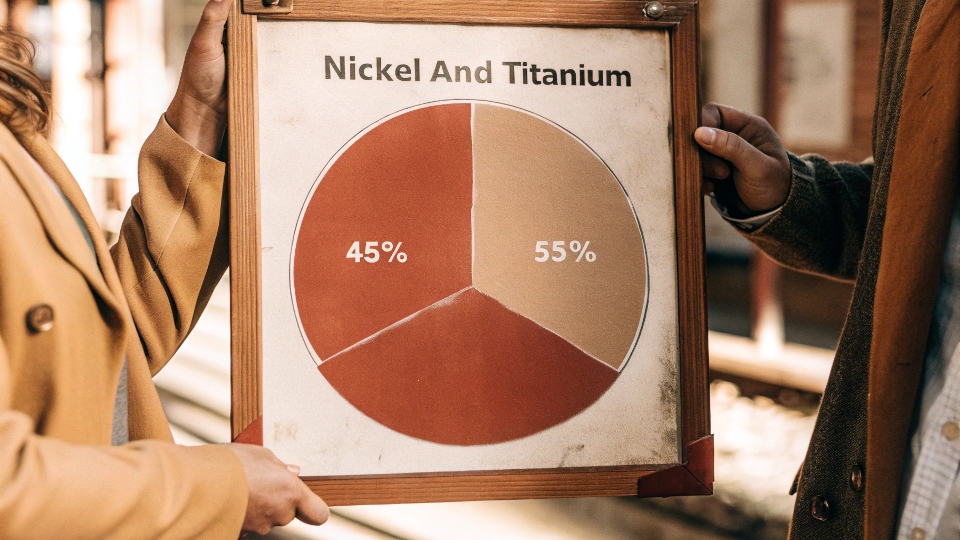

Una aleación típica de níquel y titanio tiene un porcentaje atómico casi igual de ambos elementos. En peso, esto se traduce en aproximadamente 55% de níquel y 45% de titanio. Pequeños cambios en esta proporción pueden alterar significativamente el rendimiento de la aleación y la temperatura de transición.

Esta proporción específica es el factor más importante para controlar las propiedades del nitinol. Aunque el objetivo suele ser una relación atómica de uno a uno -un átomo de níquel por cada átomo de titanio-, el porcentaje en peso es diferente porque los átomos de níquel son más pesados que los de titanio. Esta es la razón por la que verá especificaciones que indican alrededor de 55% de níquel en peso. Esta balanza es increíblemente sensible. Un cambio de tan sólo 0,1% en el contenido de níquel puede modificar la temperatura de activación de la aleación hasta en 10°C. Esto es fundamental para los dispositivos médicos, que deben diseñarse para activarse con precisión a la temperatura del cuerpo humano (alrededor de 37 °C). En una ocasión, un cliente nos envió una muestra de una pieza médica defectuosa para que la analizáramos. Utilizando la máquina de Espectroscopia de Energía Dispersiva de Rayos X (EDS) de nuestro laboratorio, confirmamos que la composición era de 54,8% de níquel, lo que se ajustaba perfectamente a la norma ASTM F2063. Esto nos indicó que el material en sí era correcto y que el fallo se debía probablemente al diseño de la pieza, no a su composición química.

Comprender el porcentaje atómico y ponderal

Para los ingenieros y jefes de producto, es útil saber por qué estos dos porcentajes son diferentes.

| Medición | Níquel (Ni) | Titanio (Ti) | Por qué es importante |

|---|---|---|---|

| Porcentaje atómico | ~50% | ~50% | Esto describe la estructura cristalina atómica 1:1 ideal para obtener el mejor efecto de memoria de forma. |

| Peso Porcentaje | ~55% | ~45% | Es lo que se utiliza para pedir y verificar la materia prima, ya que es la forma en que se mide la composición. |

Conclusión

La aleación de níquel y titanio existe como material inteligente Nitinol. Es muy diferente del titanio estándar y resulta vital para aplicaciones médicas y aeroespaciales avanzadas. Conocer sus propiedades únicas es crucial.