Worried about wasted heat and high energy bills in your plant? This lost energy hurts your bottom line. An air heat exchanger captures and reuses that heat effectively.

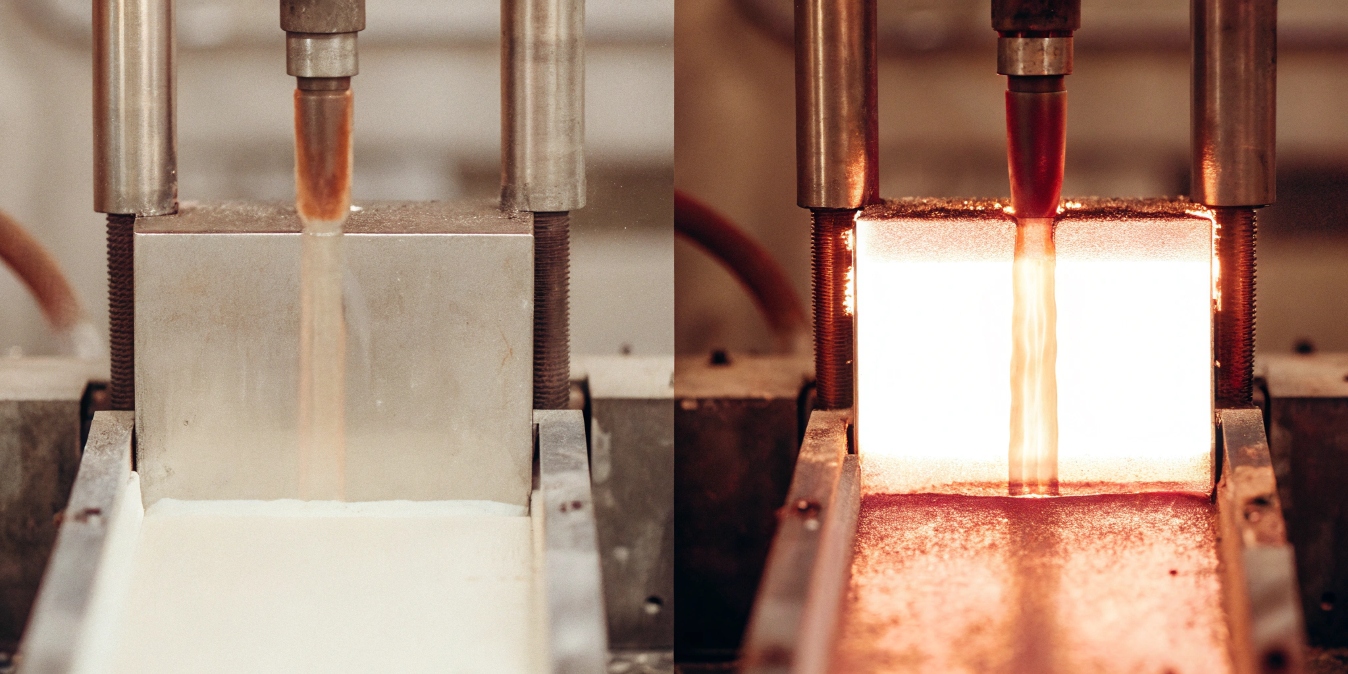

An air heat exchanger transfers heat from one air stream to another without mixing them. Hot exhaust air passes over metal plates or tubes, warming them. Cooler incoming air then flows over the other side, picking up the heat and saving energy.

This basic concept is simple, but the real value is in the details. The design and materials change everything, especially in tough industrial settings. I’ve seen clients gain massive efficiency just by choosing the right type. So, how do specific designs like air-to-air models handle this process?

How does the air to air heat exchanger work?

Need to recover heat between two air streams without them ever touching? Cross-contamination is a big risk in chemical plants. An air-to-air exchanger uses separate channels for safe heat transfer.

In an air-to-air heat exchanger, two separate air streams flow through adjacent channels, divided by a conductive metal wall. Heat moves from the hot stream through the wall to the cold stream. The air itself never mixes, ensuring process purity.

I remember working with a client in the petrochemical industry. They were venting hot, corrosive exhaust gas. At the same time, they were spending a lot to heat fresh intake air for another process. The risk of mixing these two streams was unacceptable.

Why Material Choice is Critical

This is where custom design comes in. We recommended an air-to-air plate heat exchanger. The design keeps the two air streams completely separate. The key was the material. Standard steel would corrode in weeks. We specified Grade 2 titanium for the plates because of its incredible corrosion resistance. This choice prevents leaks and ensures a long service life, even with aggressive chemicals involved.

Common Applications and Benefits

The benefits go beyond just preventing contamination. Using titanium also improves thermal efficiency. Here’s a quick breakdown of where these are used and why.

| Industry | Application | Key Benefit |

|---|---|---|

| Petrochemical | Recovering heat from exhaust fumes | Corrosion Resistance |

| HVAC | Pre-heating fresh winter air | Energy Savings |

| Food Processing | Drying processes | Purity & Hygiene |

By matching the right design and material, my client didn’t just solve a contamination problem. They turned waste heat into a valuable asset, cutting their energy costs significantly.

How does a heat exchanger work for dummies?

Does "heat exchanger" sound like a term from an engineering textbook? The jargon can make a simple idea seem confusing. Let’s break it down to its simplest form.

Imagine two pipes running side-by-side. One pipe carries hot liquid, and the other carries cold liquid. Heat from the hot pipe travels through the metal wall and warms up the cold liquid, without the two ever mixing. That’s a heat exchanger.

The two-pipe analogy is the core idea. Now, let’s make it more practical. Instead of just two pipes, imagine hundreds of thin, hollow plates stacked together. Hot fluid flows through every other channel, and cold fluid flows through the channels in between.

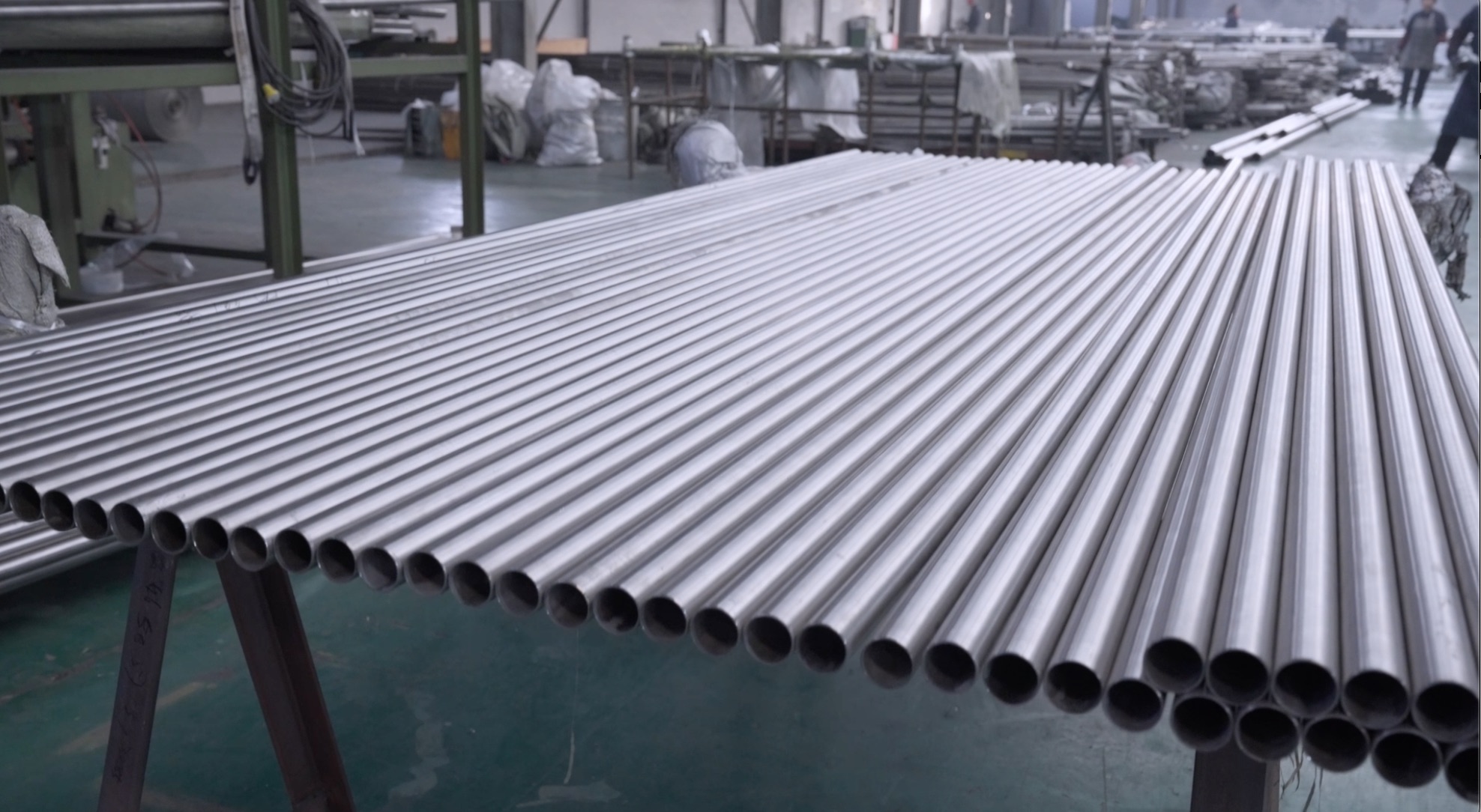

Looking for High-Quality Titanium Tubes and Pipes?

Explore our range of titanium tubing and piping solutions suited for aerospace, medical, and industrial applications. Our products are designed to meet rigorous standards and provide reliable performance in various environments.

Plates vs. Tubes

Why use plates instead of simple pipes? It’s all about surface area. The more surface area you have between the hot and cold fluids, the faster and more efficiently you can transfer heat. Think about it: a stack of thin plates has way more contact area than two round pipes. This is why plate heat exchangers are so popular. I often advise clients like Ahmed, the distributor in Turkey, that titanium plate heat exchangers are a great product to stock. They are compact and highly efficient for their size.

Looking for Durable Titanium Sheets and Plates?

Explore our range of high-quality titanium sheets and plates designed for aerospace, chemical, and marine applications. Our products meet rigorous standards and ensure reliability in demanding environments.

The Role of the Metal Wall

The wall separating the fluids does two jobs. First, it keeps them from mixing. Second, it conducts heat. The material we use for that wall is very important. Copper is a great conductor, but it corrodes easily. Stainless steel is better, but in many chemical applications, it’s not enough. That’s why we frequently use titanium. It has good heat transfer properties and is exceptionally resistant to corrosion from things like saltwater or acids. This makes the equipment last longer and work more reliably.

What is the basic working principle of a heat exchanger?

You get the basic idea, but what’s the actual science making it work? Not knowing the core principle can lead to poor choices. It’s all about thermodynamics and efficient design.

The basic working principle is thermal energy transfer through conduction. Heat naturally moves from a hotter substance to a colder one. A heat exchanger uses a conductive material, typically metal, to facilitate this transfer between two fluids while keeping them separate.

This principle comes from the Second Law of Thermodynamics. Heat always flows from hot to cold to reach a balance, or equilibrium. A heat exchanger is just a device engineered to make this natural process happen very efficiently. When we design a unit, we focus on maximizing this transfer.

Maximizing Heat Transfer

Several factors influence efficiency. We consider the fluid properties, the temperature difference, and the flow rate. But two of the biggest design choices are the surface area and the flow pattern. As I mentioned, more surface area means more heat transfer. The other key is how the fluids flow relative to each other.

Flow Patterns: Counter-Flow vs. Parallel-Flow

The flow arrangement has a huge impact on efficiency.

| Flow Type | Description | Efficiency |

|---|---|---|

| Parallel-Flow | Hot and cold fluids enter at the same end and flow in the same direction. | Moderate |

| Counter-Flow | Fluids enter at opposite ends and flow in opposite directions. | High |

Counter-flow is almost always preferred. As the cold fluid gets warmer, it meets hotter and hotter sections of the hot fluid’s path. This maintains a more consistent temperature difference along the entire length of the exchanger, leading to much more effective heat transfer. When I consult with manufacturing partners in Xi’an, we always model the flow dynamics to ensure a counter-flow design is used wherever possible.

What is the difference between an air exchanger and a heat exchanger?

Do the terms "air exchanger" and "heat exchanger" sound like the same thing? This common confusion can lead to very costly mistakes. Let me clarify the key difference.

The main difference is purpose. An air exchanger’s primary job is ventilation—replacing stale indoor air with fresh outdoor air. A heat exchanger’s primary job is to transfer heat between any two fluids (gases or liquids), not necessarily for ventilation.

While their names are similar, their jobs are different. Think of it this way: an air exchanger focuses on air quality, while a heat exchanger focuses on energy recovery.

The Main Job of Each Device

An air exchanger is all about ventilation. Its goal is to bring fresh outside air in and push stale inside air out. You see these in homes and office buildings. On the other hand, the heat exchangers I typically work with are for heavy industry. Their goal is purely to move thermal energy. For example, using hot waste gas to pre-heat a chemical before it enters a reactor. The fluids could be air, water, oil, or acids.

Where They Overlap

The confusion happens because some devices do both jobs. A Heat Recovery Ventilator (HRV) is a type of air exchanger that also includes a heat exchanger core. It ventilates a building but uses the heat from the outgoing stale air to warm up the incoming fresh air. This is a perfect example of both principles at work. However, the industrial heat exchangers we build from titanium alloys for chemical plants are highly specialized for thermal transfer in corrosive environments. They are not designed for simple building ventilation1. The focus is on processes like condensation or heating, which are far more demanding.

Conclusion

In short, heat exchangers use conduction to transfer heat between separate fluids. The right design and material, like titanium, are crucial for efficiency and durability in demanding industrial applications.

-

Explore the role of ventilation in maintaining air quality and energy efficiency. ↩

[^1] showing hot and cold air flows](https://titonestmetal.com/wp-content/uploads/2025/08/an-air-heat-exchanger-transfers-heat-from-one-ai.jpg)