Are you confused by terms like fabrication and milling? This confusion can lead to project mistakes and ordering the wrong materials. Let’s clarify these key manufacturing processes for you.

Metal fabrication is a broad process of building metal structures through cutting, forming, and joining. In contrast, steel milling is a specific machining process that uses rotary cutters to remove material from a steel workpiece. They are fundamentally different, though both are used in manufacturing.

To really understand the difference, you need a clear grasp of what "metal fabrication" truly means. The term is broad, and people on my factory floor use it to describe a whole series of actions. It’s more than just one thing. It’s a journey from raw metal to a finished product. Let’s break down what fabrication is, how it’s categorized, and how it compares to other critical processes like machining. This will help you speak confidently with engineers and suppliers.

What is meant by metal fabrication?

Do project requirements get confusing because of vague definitions? This can cause you to miscommunicate your needs to suppliers. Here is a clear, practical definition from the factory floor.

Metal fabrication is the complete process of transforming raw metals into finished products. This happens through cutting, bending, and assembling. At my plant, we use these methods to produce 3,500 tons of titanium each year for many industries.

At its core, metal fabrication is about construction. You start with stock metal materials, like sheets, plates, or bars, and build something new. It’s a creative process guided by precise engineering plans. I see this every day in our Baoji facility. We take raw titanium sponge, melt it, form it into ingots, and then fabricate it into parts for chemical plants or aircraft. The process can be broken down into three main stages.

The Stages of Fabrication

| Stage | Description | My Plant’s Example |

|---|---|---|

| Cutting | This is the first step where the raw material is cut to the required size and shape. It can be done by shearing, sawing, or with advanced methods. | We use high-pressure waterjet cutting for titanium plates. It cuts precisely without creating a heat-affected zone, which protects the metal’s properties. |

| Forming | After cutting, the metal is bent, stamped, or shaped. This is often done using pressure and dies. For some metals, heat is required to make them more malleable. | Our team uses isothermal forging1 for complex titanium parts. This means we heat both the workpiece and the die to the same high temperature, allowing us to shape the strong alloy with incredible precision. |

| Assembling | Finally, the separate pieces are joined together. The most common method is welding, but riveting or bonding with adhesives are also used. | Assembling titanium is very specialized. We must weld it in an inert argon gas environment. This prevents the hot metal from reacting with oxygen or nitrogen in the air, which would make the weld brittle and weak. |

What are the three types of metal fabrication?

Does "fabrication" seem like just one big, single process? This simple view hides important differences that can affect your project’s cost, quality, and timeline. Let’s look at the three main categories.

The three main types of fabrication are structural, industrial, and commercial. Each serves a different purpose, from building skeletons for skyscrapers to creating custom equipment for a chemical plant or parts for commercial products.

Thinking about fabrication in categories helps you match the process to the product. As an engineer, I have to consider the final application to recommend the right material and fabrication approach. For instance, the requirements for a structural beam are very different from those for a high-purity chemical reactor. The scale, materials, and precision needed vary greatly. These differences directly impact the choice of a fabrication partner and the overall cost of a project. Let’s explore each type.

A Closer Look at Fabrication Types

| Fabrication Type | Primary Goal | Common Materials | Example Products |

|---|---|---|---|

| Structural | To create the "bones" of large projects like buildings and bridges. The focus is on strength and load-bearing capacity. | Carbon Steel (I-beams, bars, plates) | Building frames, platforms, support structures, bridge components. |

| Industrial | To build heavy-duty equipment that handles processing, manufacturing, or storage. Focus is often on durability and resistance to pressure, temperature, or corrosion. | Stainless Steel, Carbon Steel, Titanium, Zirconium | Pressure vessels, chemical reactors, industrial tanks, heat exchangers, large material handling equipment. |

| Commercial | To create products for commercial businesses or sometimes direct consumer use. The focus often includes aesthetics and surface finish alongside function. | Stainless Steel, Aluminum | Restaurant kitchen surfaces, store fixtures, architectural railings, appliance panels. |

My work is mainly in industrial fabrication. When a product manager like Lisa needs a tank for a highly corrosive chemical, she can’t use standard steel. She needs a material like titanium. Our plant supplies the raw titanium plate, and a specialized industrial fabricator then cuts, forms, and welds it into the final vessel, following strict codes like ASME.

What is the difference between steel fabrication and metal fabrication?

Do people you work with use "steel fabrication" and "metal fabrication" as if they mean the same thing? This common mix-up can cause you to overlook specialized materials like titanium.

Steel fabrication is a specialty within the broader category of metal fabrication. Metal fabrication covers all metals, including aluminum, copper, and alloys like titanium, while steel fabrication focuses only on working with steel.

The easiest way to think about it is this: all steel fabrication is metal fabrication, but not all metal fabrication is steel fabrication. It’s a matter of specialization. A shop that says they are a "steel fabricator" is telling you their expertise, equipment, and processes are optimized for steel. They are experts in welding carbon steel or forming stainless steel. However, my plant works with titanium and zirconium. These are considered exotic or reactive metals. They require entirely different knowledge and equipment. You can’t just take a titanium plate to a standard steel shop and expect good results. The process differences are significant.

Process Differences: Steel vs. Titanium

| Process Step | Standard Steel Fabrication | Titanium Fabrication |

|---|---|---|

| Welding | Can be done in open air. Standard MIG or TIG welding is common. Contamination is a lower risk. | Must be done in an inert argon gas shield. Any exposure to air ruins the weld. Requires specialized TIG welding skills and equipment. |

| Forming | Can often be cold-formed or bent at room temperature using standard press brakes. | Often requires heat to be formed, as it is less ductile. Our isothermal forging1 process is an example of this high-temperature need. |

| Cutting | Typically cut with plasma, oxy-fuel, or abrasive saws. These are fast and cost-effective methods. | Often requires waterjet or band saws with specific coolant and blade speeds to avoid heat buildup and material contamination. |

| Contamination | Less sensitive to surface contamination from things like oil, dirt, or iron particles. | Extremely sensitive. Even a fingerprint on the metal before welding can introduce impurities and create a weak point. |

Because of this, when Lisa needs a part made from one of our titanium grades, I always recommend she works with a fabricator who has proven experience with reactive metals. It’s a different world from standard steel fabrication.

What is the difference between metal fabrication and machining?

Do fabrication and machining sound like the same thing to you? Confusing the two might mean you specify a process that can’t deliver the precision or tolerances your product needs. Let’s draw a clear line.

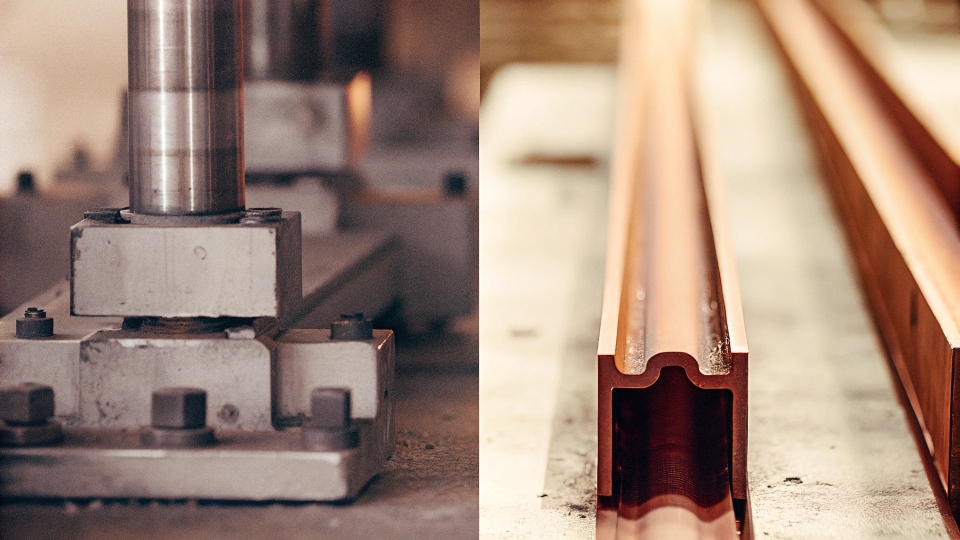

Metal fabrication builds the general shape of a product by cutting, bending, and welding parts together. Machining is a a subtractive process that refines a part to its final, precise dimensions using tools like mills and lathes.

Think of it as a two-step workflow. Fabrication creates the structure, and machining creates the precision. In my R&D work, we rely on both. For example, we might fabricate a large near-net shape forging for an aerospace client. This part is almost the right shape but doesn’t have the exact dimensions or smooth surfaces needed to fit into an airplane engine. That’s where machining comes in. The fabricated forging goes to a CNC machining center. There, computer-controlled tools carefully remove small amounts of metal to achieve the extremely tight tolerances and perfect surface finish required by aerospace standards. Fabrication gets you 95% of the way there; machining delivers the final 5% of critical precision.

Comparing Fabrication and Machining

| Feature | Metal Fabrication | Metal Machining |

|---|---|---|

| Primary Goal | Creating the overall shape and structure. | Achieving high precision, tight tolerances, and a specific surface finish. |

| Process Type | Formative (bending), Additive (welding), and rough cutting. | Subtractive (removing material). |

| Key Processes | Welding, Bending, Shearing, Rolling. | Milling, Turning (Lathe), Drilling, Grinding. |

| End Result | A complete assembly or structure, like a frame or a tank. | A finished component with precise features, like a threaded hole or a bearing surface. |

| Typical Tolerance | Looser tolerances, often measured in millimeters or fractions of an inch. | Very tight tolerances, often measured in micrometers or thousandths of an inch. |

So, returning to the original question, "steel milling" is a type of machining performed on steel. It is a precision process, and it is very different from metal fabrication, which is a structural construction process.

Conclusion

Understanding fabrication, machining, and milling helps you communicate clearly. This clarity ensures you choose the right process and material, like titanium, for your most demanding industrial applications.