¿Le cuesta encontrar un material para piezas complejas y sometidas a grandes esfuerzos? La fabricación aditiva ofrece una solución, pero elegir el metal adecuado es clave. El titanio está dando un paso adelante para afrontar este reto.

Sí, la demanda de titanio está transformando la fabricación aditiva. Su fuerza única, su bajo peso y su resistencia a la corrosión permiten crear piezas de alto rendimiento en los campos aeroespacial y médico que antes eran imposibles de fabricar.

El auge del titanio en Impresión 3D1 no es sólo una tendencia. Es un cambio fundamental en la forma de enfocar la fabricación de aplicaciones críticas. Por mi trabajo aquí en Baoji, veo que los jefes de producto como Lisa se hacen más preguntas al respecto. Necesitan entender qué hace que el titanio sea tan especial para este proceso y cómo está evolucionando esta tecnología. Exploremos las preguntas clave que los jefes de producto me hacen cada día.

¿Por qué el titanio es el metal preferido para la impresión 3D?

¿Necesita piezas ligeras e increíblemente resistentes? Los métodos tradicionales a menudo obligan a hacer concesiones. El titanio en impresión 3D ofrece lo mejor de ambos mundos sin concesiones.

El titanio se utiliza en impresión 3D por su asombrosa relación resistencia-peso, su excelente resistencia a la corrosión y su biocompatibilidad. Estas características lo hacen perfecto para crear piezas duraderas y ligeras para sectores exigentes como el aeroespacial y el de los dispositivos médicos, donde el rendimiento es fundamental.

Analicemos exactamente por qué el titanio es una estrella en el mundo de la fabricación aditiva. No se trata de una sola cualidad, sino de una combinación de propiedades que lo hacen especialmente adecuado para construir la próxima generación de componentes. En mi planta producimos polvos de titanio específicamente para estas aplicaciones, y puedo ver los resultados de primera mano.

La ventaja de la fuerza

El titanio es tan resistente como muchos aceros, pero aproximadamente 45% más ligero. Esta relación resistencia-peso es su cualidad más famosa. Para un sector como el aeroespacial, esto supone un cambio radical. He trabajado con clientes que han sustituido un soporte aeronáutico de aluminio mecanizado por otro de titanio impreso en 3D. La nueva pieza era más ligera, más resistente y tenía un diseño más eficiente, lo que contribuía directamente al ahorro de combustible durante la vida útil de la aeronave. La capacidad de imprimir estructuras internas complejas también significa que podemos utilizar menos material para conseguir la misma resistencia, algo imposible con la forja o el mecanizado tradicionales.

Durabilidad sin igual

El titanio forma de forma natural una capa protectora de óxido cuando se expone al aire. Esto lo hace increíblemente resistente a la corrosión del agua salada, los productos químicos industriales y otros entornos agresivos. Es una gran ventaja para piezas que deben durar mucho tiempo con un mantenimiento mínimo. Un jefe de producto de una empresa de equipos químicos me dijo hace poco que habían cambiado a una válvula de titanio impresa en 3D. La versión anterior de acero inoxidable fallaba con regularidad, pero la pieza de titanio ha funcionado a la perfección, alargando considerablemente su vida útil.

Ideal para uso médico

El cuerpo humano acepta el titanio sin provocar una reacción inmunitaria. Esta propiedad se denomina biocompatibilidad. Hace del titanio la mejor elección para implantes médicos. Con la impresión 3D, podemos ir un paso más allá. Podemos crear implantes ortopédicos a medida, como encajes de cadera o jaulas espinales, basándonos en el escáner de un paciente. El proceso de impresión también puede crear estructuras porosas similares al hueso que estimulan el crecimiento del hueso del propio paciente en el implante. Así se consigue una unión más fuerte y permanente.

¿Cuál es la mayor tendencia en la fabricación aditiva de metales?

¿Considera que la fabricación tradicional limita su libertad de diseño? Es difícil crear piezas complejas de forma eficiente. La fabricación aditiva de metales está derribando estas barreras con nuevas posibilidades.

La mayor tendencia es el cambio hacia las aleaciones de alto rendimiento, especialmente el titanio, para crear piezas complejas de peso optimizado. Industrias como la aeroespacial, la automovilística y la energética lo están adoptando para mejorar la eficiencia y el rendimiento, pasando de la creación de prototipos a la producción a gran escala de componentes críticos.

Desde mi punto de vista como proveedor, la tendencia es clara: la impresión 3D en metal ya no sirve únicamente para fabricar prototipos. Ahora es un método de fabricación serio para piezas finales de misión crítica. Estamos asistiendo a un rápido crecimiento de la demanda en varios sectores clave. Cada industria utiliza la tecnología para resolver retos diferentes, pero igualmente difíciles. Este paso de la creación de prototipos a la producción es el mayor cambio que se está produciendo actualmente en la industria.

Aeroespacial y defensa

Este sector es el mayor impulsor de la tendencia. Los objetivos son sencillos: aligerar los aviones para ahorrar combustible y mejorar el rendimiento. La fabricación aditiva con titanio permite a los ingenieros utilizar el "diseño generativo". En este caso, los algoritmos de software diseñan la forma más eficiente para una pieza en función de sus requisitos de carga. Las piezas resultantes suelen tener un aspecto orgánico y esquelético. Utilizan la cantidad mínima de material necesario, lo que las hace increíblemente ligeras y resistentes. Suministramos mucho polvo de titanio para este tipo de piezas, como soportes estructurales, componentes del tren de aterrizaje y álabes de turbina.

Médico y dental

La tendencia en medicina es la personalización. No hay dos pacientes iguales, ¿por qué iban a serlo sus implantes? Con la impresión en 3D, un cirujano puede conseguir un implante específico para un paciente que encaje a la perfección. Esto reduce el tiempo de cirugía, mejora los resultados y acelera la recuperación. Hemos visto un enorme aumento de los pedidos de nuestros polvos de titanio más finos y de mayor pureza sólo para este mercado. Se utiliza para todo, desde prótesis de rodilla y cadera hasta accesorios dentales personalizados y guías quirúrgicas.

Automoción y energía

Estos sectores han tardado un poco más en adoptar la tecnología, pero se están poniendo al día rápidamente. En la automoción de alto rendimiento, los equipos utilizan titanio impreso en 3D para componentes ligeros de coches de carreras con el fin de obtener una ventaja competitiva. En el sector sector energético2Las empresas están imprimiendo piezas duraderas para equipos de perforación y exploración. Estos componentes deben soportar presiones extremas y entornos corrosivos en el fondo del pozo, un trabajo perfecto para el titanio. Esta tecnología les permite crear y sustituir rápidamente piezas críticas en lugares remotos.

¿Qué grado de titanio es mejor para la fabricación aditiva?

¿Se siente abrumado por las diferentes calidades de titanio disponibles? Elegir el grado equivocado puede provocar fallos costosos. Simplifiquemos el proceso de selección para aplicaciones de impresión 3D.

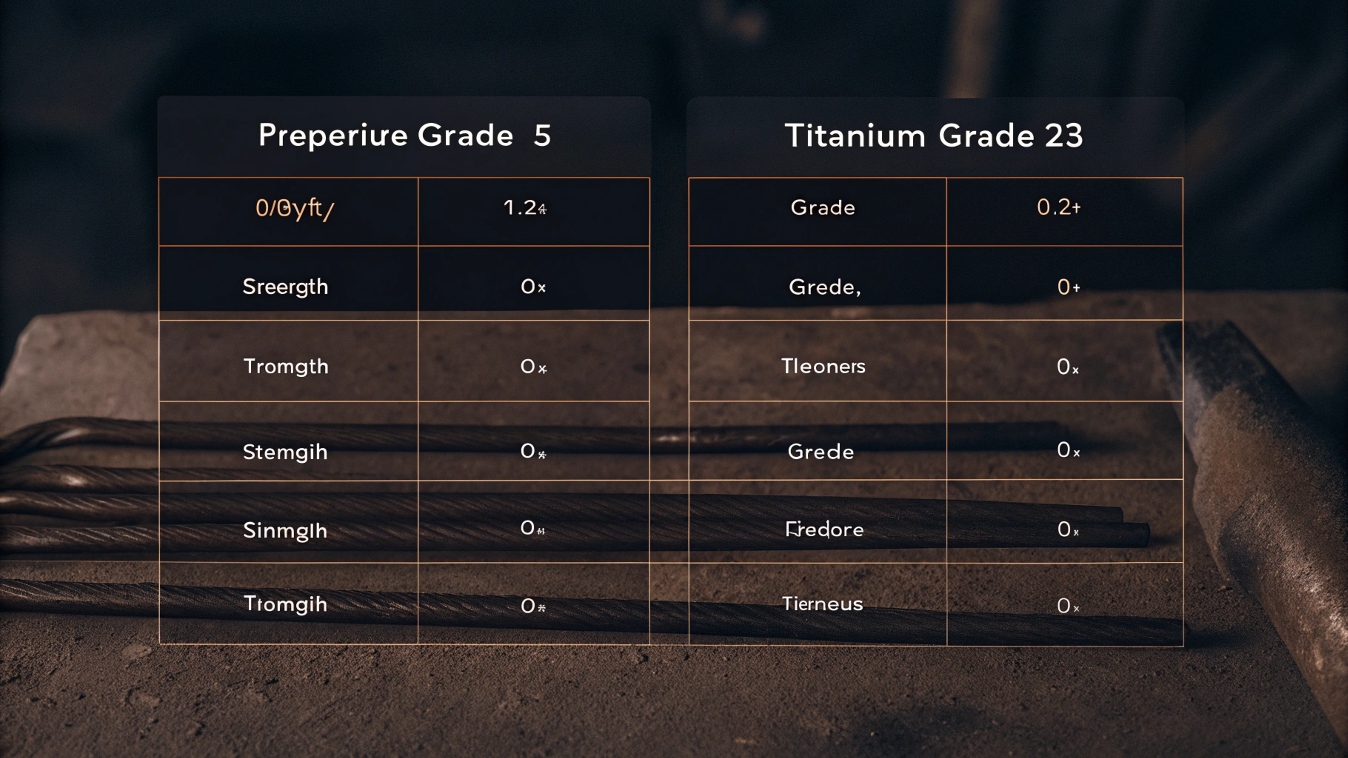

Las aleaciones de titanio más comunes para la fabricación aditiva son el Grado 5 (Ti-6Al-4V) y el Grado 23 (Ti-6Al-4V ELI). El Grado 5 ofrece una alta resistencia, mientras que el Grado 23 proporciona una ductilidad y una resistencia a la fractura mejoradas, por lo que resulta ideal para implantes médicos y piezas aeroespaciales.

Cuando un jefe de producto como Lisa me pregunta qué polvo de titanio utilizar, la respuesta casi siempre se reduce a dos aleaciones principales. Aunque hay muchos grados de titanio, el Grado 5 y el Grado 23 dominan el panorama de la fabricación aditiva. Ambos tienen una excelente capacidad de impresión, pero sus pequeñas diferencias químicas los hacen adecuados para aplicaciones muy diferentes. Comprender estos dos grados es clave para hacer la elección correcta para su proyecto.

El caballo de batalla: Grado 5 (Ti-6Al-4V)

Se trata de la aleación de titanio más utilizada en el mundo, no sólo en impresión 3D. Es una aleación alfa-beta, lo que le confiere una excelente combinación de alta resistencia, bajo peso y buena resistencia a la corrosión. Se trata de una aleación fiable y polivalente. Como es tan común, sus propiedades están muy bien documentadas, lo que da mucha confianza a los ingenieros. Suelo recomendar el polvo de grado 5 para aplicaciones generales de alta resistencia, como componentes estructurales aeroespaciales, piezas de automoción de alto rendimiento y equipos industriales en los que la biocompatibilidad no es la principal preocupación.

El estándar médico: Grado 23 (Ti-6Al-4V ELI)

El grado 23 es químicamente muy similar al grado 5, pero con una diferencia crucial. Las siglas "ELI" significan "Extra Low Interstitials". Esto significa que tiene niveles más bajos de oxígeno, carbono y nitrógeno. Estos elementos pueden hacer que la aleación sea más quebradiza. Al reducirlos, el Grado 23 se vuelve más dúctil y tiene una mayor resistencia a la fractura. Esto significa que es mucho menos probable que se agriete bajo tensión, una característica crítica para algo que está dentro del cuerpo humano. Esta tolerancia superior a los daños hace que el grado 23 sea el estándar para implantes médicos y dentales, así como para piezas aeroespaciales críticas y sensibles a la fractura.

Cuadro comparativo

Para simplificarlo, he aquí una tabla que suelo compartir con los jefes de producto para ayudarles a decidir.

| Característica | Grado 5 (Ti-6Al-4V) | Grado 23 (Ti-6Al-4V ELI) |

|---|---|---|

| Características principales | Alta resistencia, buen rendimiento general | Mayor pureza, ductilidad y resistencia a la fractura superiores |

| Aplicación principal | Piezas estructurales aeroespaciales, componentes industriales | Implantes médicos y dentales, piezas aeroespaciales críticas |

| Ventajas clave | Ampliamente disponibles y bien comprendidos | Excelente biocompatibilidad y tolerancia a los daños |

¿Es la impresión 3D con titanio demasiado cara para mi proyecto?

¿Le preocupa el elevado coste de la impresión 3D de titanio? El precio puede parecer intimidante. Pero si nos centramos solo en el coste inicial, se pierde de vista el valor a largo plazo.

Sí, la impresión 3D con titanio es cara de entrada. El elevado coste se debe a la producción de polvo de titanio de alta calidad y al proceso de impresión, que consume mucha energía. Sin embargo, para aplicaciones de alto valor, el coste se justifica por la creación de piezas con un rendimiento superior, una vida útil más larga y diseños imposibles de conseguir de otro modo.

Esta es la pregunta más frecuente que me hacen, y es importante. La sorpresa es real. Sin embargo, una simple comparación del coste por kilogramo con la fabricación tradicional es engañosa. El verdadero valor de la fabricación aditiva con titanio no está en hacer la misma pieza más barata, sino en hacer una pieza mejor que antes era imposible. Hay que considerar la propuesta de valor total, no sólo el coste de producción inicial.

¿Por qué es caro?

Hay dos razones principales que explican el elevado coste. Como ingeniero en una planta de titanio, me enfrento a estos factores todos los días.

Primero, producción de polvo es un proceso muy técnico. Para obtener el polvo de titanio perfectamente esférico, muy puro y fino que se necesita para la impresión 3D, utilizamos un método llamado atomización con gas. Consiste en fundir un electrodo de titanio en el vacío y luego golpear el metal fundido con un chorro de gas inerte a alta presión. Es complejo y requiere mucha energía, lo que encarece la materia prima.

En segundo lugar, la proceso de impresión es caro. Las máquinas que utilizan láseres de alta potencia o haces de electrones para fundir el polvo capa por capa pueden costar más de un millón de dólares. Requieren una atmósfera de gas inerte estrictamente controlada y consumen mucha energía.

¿Cuándo merece la pena?

La tecnología tiene sentido desde el punto de vista financiero cuando crea un valor que compensa su coste. Esto suele ocurrir de dos maneras.

El primero es consolidación de partes. Un ingeniero puede diseñar una sola pieza impresa que sustituya a un conjunto de 10 o 20 componentes individuales que antes se atornillaban o soldaban. Esto ahorra mano de obra de montaje, reduce los posibles puntos de fallo y suele dar lugar a un producto final más ligero.

El segundo está en aplicaciones de alto valor. Para un satélite, cada gramo de peso ahorrado vale miles de dólares en costes de lanzamiento. Para un implante médico, un ajuste personalizado puede mejorar drásticamente la calidad de vida del paciente. En estos casos, el alto rendimiento, la mayor vida útil y la libertad de diseño que ofrece el titanio impreso en 3D proporcionan un retorno de la inversión que supera con creces el elevado precio inicial.

Conclusión

La impresión 3D de titanio está transformando la fabricación al permitir piezas fuertes, ligeras y complejas. Aunque costosa, su valor en aplicaciones críticas es innegable y su importancia sigue creciendo.