Struggling with brittle titanium welds? Contamination can ruin expensive materials and stop a project in its tracks, costing you both time and money.

Yes, titanium is generally harder to weld than stainless steel. It demands a completely pure, inert gas shield1 to prevent contamination from the air. This contamination can make the final weld brittle and cause it to fail under stress, a problem stainless steel doesn't have.

Understanding why titanium needs such special care is the first step. The difficulty isn't just about a welder's skill; it's about the basic chemistry of the metal. Let's break down what makes welding titanium a unique challenge. This knowledge will help you source materials and plan your projects much better. It will also help you advise your own customers, like I do with clients such as Ahmed, a metal distributor in Turkey.

Is titanium harder to weld than stainless?

Ever wonder why your titanium welds look perfect but fail under stress? The invisible enemy is atmospheric contamination, a problem much less common when welding stainless steel.

Titanium welding is harder because the metal has a high reactivity with oxygen, nitrogen, and hydrogen. This reaction happens at temperatures above 427°C (800°F). It requires a pristine, inert argon gas atmosphere, while stainless steel is more forgiving, often needing only standard gas shielding.

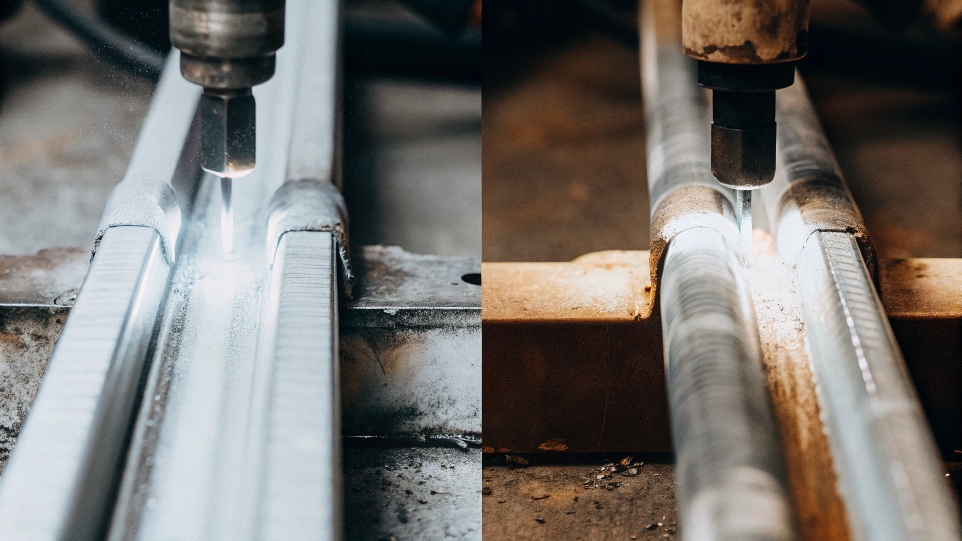

The Crucial Role of Shielding

The core difference comes down to how each metal behaves when it gets hot. Stainless steel contains chromium, which forms a thin, tough, and self-healing layer of chromium oxide on the surface. This layer protects the metal underneath. When you weld titanium, the situation is the opposite. Hot titanium is like a sponge for gases in the air, especially oxygen. It eagerly absorbs them, which creates brittle spots in the metal. This damage is permanent. You can't fix it. To prevent this, you must shield the titanium from all air until it cools down. This means using a primary shield from the torch, a "trailing shield" that follows the torch, and a "back-purge2" to protect the backside of the weld. I have seen projects fail because the back-purge was not set up correctly.

Material Properties at Welding Temperatures

In my facility, we use special argon shielding chambers for critical medical and aerospace parts. We have to do this because the standards for these industries are incredibly high. A small amount of contamination can lead to catastrophic failure. For Ahmed's business in Turkey, I advised him to set up a dedicated "clean area" just for titanium work. This prevents any cross-contamination from other metal fabrication, ensuring his customers get the pure, strong welds they expect. The table below shows the key differences.

| Característica | Titanium Welding | Stainless Steel Welding |

|---|---|---|

| Primary Challenge | Reactivity with air at high temp | Heat distortion, sensitization |

| Shielding Gas | 100% pure Argon | Argon/CO2 mixes often used |

| Shielding Method | Torch, trailing shield, & back-purge | Often just torch shielding |

| Weld Puddle | Fluid and very clear when clean | More viscous and slow-moving |

| Post-Weld Color | Light straw to blue is good | Dark discoloration indicates heat |

Is it hard to weld titanium?

Are you worried about the high skill level needed for titanium work? It is true that mistakes are expensive, but the process is very manageable with the right training and preparation.

Yes, titanium is considered a difficult material to weld. The process is not forgiving. Absolute cleanliness is critical, and the welder must be highly skilled a maintaining a perfect inert gas shield. Any small error can make the weld brittle and useless.

The Non-Negotiable: Cleanliness

You cannot overstate the need for cleanliness. Before you strike an arc, the titanium part and the filler rod must be perfectly clean. This means using a specific solvent, like acetone, to wipe down all surfaces. You have to remove every trace of oil, dirt, paint, or moisture. Even the oil from a fingerprint can introduce enough hydrogen and carbon to ruin a weld. I remember a case back in 2012 with a client. Their parts were failing quality control tests over and over. After a long investigation, we traced the problem back to the welder's gloves. They were not changing them often enough, and a small amount of contamination was getting onto the filler rods. We changed the procedure, and the problem disappeared.

The Welder's Skill and Technique

Welding titanium is a job for an expert. Since 2008, we have made it a standard that any of our manufacturing partners must have titanium-specific training programs for their welders. A titanium welder needs incredible control. They mostly use the TIG (Tungsten Inert Gas) process because it offers precise heat control. The welder must keep the hot end of the filler rod under the flow of argon gas at all times. If they pull it out of the gas shield, it will get contaminated, and that rod is now scrap. They must also ensure the argon gas keeps flowing over the weld until it cools to below 427°C (800°F). This requires patience and a deep understanding of the material.

Which metal is the most difficult to weld?

Do you think titanium is the ultimate welding challenge? There are other metals out there that can make even the most experienced welders nervous because of their tricky properties.

While titanium is very difficult, many experts say magnesium is the most difficult metal to weld in common industrial use. Its high thermal conductivity, low melting point, and extreme fire risk make it exceptionally challenging and dangerous without very specialized procedures.

A Spectrum of Difficulty

The term "most difficult" really depends on what you mean. Different metals present different problems. Titanium's main challenge is its reactivity with the atmosphere, which is a chemical problem. You solve it with perfect cleanliness and shielding. Other metals are difficult for physical reasons. For example, some high-strength aluminum alloys are very prone to cracking right after they are welded. Aluminum also conducts heat so well that it can be hard to get a good weld puddle3 started without distorting the whole part. This makes the welder's job very different from welding titanium or steel. For a distributor like Ahmed, understanding this spectrum helps him manage his inventory and talk to customers.

Why Other Metals Can Be Harder

Magnesium is a great example of a harder metal to weld. It burns in open air, so there is a serious fire risk if you are not careful. It also has a very low melting point and transfers heat quickly, so it's easy to melt through the part. Refractory metals like tungsten and molybdenum have the opposite problem. Their melting points are so high that you need a huge amount of energy to weld them. Compared to these, titanium's challenges, while serious, are very well-understood. The table below gives a rough idea of how these metals compare.

| Metal | Primary Welding Challenge | Relative Difficulty |

|---|---|---|

| Magnesium | Extreme flammability, high conductivity | Muy alta |

| Titanio | Reactivity with atmosphere (contamination) | Alta |

| Aluminio | Oxide layer, porosity, high conductivity | Medium to High |

| Acero inoxidable | Heat distortion, carbide precipitation | Medio |

| Mild Steel | Generally forgiving | Bajo |

Is titanium or stainless steel tougher?

Are you choosing between titanium and stainless steel for a demanding job? Picking the wrong one because you misunderstood "toughness" can lead to unexpected failures and expensive redesigns.

It depends on how you define "tough." Titanium has a much higher strength-to-weight ratio, so it's "tougher" for its weight. However, some stainless steel alloys offer better ductility and impact resistance. This makes them "tougher" against sudden shocks or bending.

Strength-to-Weight Ratio: Titanium's Edge

"Toughness" in engineering means a material's ability to absorb energy and deform without breaking. But in everyday talk, people often mix it up with strength. Titanium's biggest advantage is its incredible strength for how little it weighs. The most common alloy, Grade 5 (Ti-6Al-4V), is as strong as many steels but at nearly half the weight. This is why it is the top choice for aerospace parts like landing gear or engine components. For these applications, where every gram matters, titanium is clearly the "tougher" material because it provides the required strength with a massive weight saving. No steel can compete with that.

Ductility and Impact Resistance: A Win for Steel?

However, strength is not the whole story. Ductility is also part of toughness. Ductility is how much a material can bend or stretch before it snaps. Here, many stainless steels, like the common 316L grade, perform better than titanium alloys. They can stretch a lot more before they fracture. This makes them better at absorbing sudden impacts. Think about a boat railing. You want it to bend if something hits it, not snap. This is a form of toughness where some stainless steels have an edge. When I advise my clients, I tell them to ask about the specific job. Is weight the main issue, or is the part likely to get hit hard? The answer will tell you which material is truly tougher for that situation.

| Propiedad | Typical Grade 5 Titanium | Typical 316L Stainless Steel |

|---|---|---|

| Densidad | ~4.43 g/cm³ | ~8.0 g/cm³ |

| Resistencia a la tracción | ~950 MPa | ~580 MPa |

| Strength-to-Weight | Muy alta | Medio |

| Ductility (% Elongation) | ~14% | ~40% |

| Lo mejor para | Lightweight, high-strength parts | Corrosion resistance, high-impact |

Conclusión

In short, welding titanium is harder than stainless steel due to contamination risks, and its toughness depends on the application. Proper knowledge ensures successful fabrication and material selection.