Facing constant pipe corrosion in desalination plants? This leads to expensive downtime and frequent failures. Titanium welded tubes offer a durable, long-term solution for reliable operations.

Titanium welded tubes are essential for desalination because they offer a unique combination of superior corrosion resistance to seawater, high strength, and light weight. This ensures long equipment life, reduces maintenance costs, and improves the overall efficiency and reliability of the process.

As an engineer working with titanium daily, I’ve seen firsthand how crucial material selection is. Lisa, a product manager I often work with, always asks about the specifics. She needs to explain these choices to her team and clients. Let’s break down the common questions she has, starting with the most basic one: what materials are used for the pipes?

What material is used for desalination pipes?

Selecting the wrong pipe material can cause system failures. This risks the plant’s integrity and budget. Using titanium in high-salinity areas ensures durability and cost-effectiveness.

For desalination pipes, especially in high-salinity seawater and brine lines, titanium and its alloys are the best choice. Their corrosion resistance is far superior to stainless steel, making them the standard for building long-lasting and reliable systems that require minimal maintenance.

I remember a project with a client in the Middle East. They initially used high-grade stainless steel for their brine pipelines. Within two years, they were already seeing significant pitting corrosion, leading to leaks. When Lisa’s team was specifying a new project, this story was a key factor in their decision. The main enemy in desalination is the chloride ions in hot, concentrated brine. These ions attack the protective layers of most metals, including many types of stainless steel. Titanium, however, forms a very stable and self-healing titanium dioxide (TiO₂) layer. This layer is nearly impossible for chlorides to break down, even at high temperatures.

Material Performance Comparison

I often share this simple table with product managers like Lisa. It helps her explain the value proposition to her clients and makes the choice clear.

| Feature | Titanium (Grade 2) | 316L Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|---|

| Pitting Corrosion | Excellent | Poor | Good |

| Crevice Corrosion | Excellent | Poor | Moderate |

| Lifespan in Brine | >20 years | 2-5 years | 5-10 years |

| Initial Cost | High | Low | Medium |

| Lifetime Cost | Low | High | Medium |

This comparison shows the whole picture. The initial investment for titanium is higher. But the total cost of ownership is much lower because there are fewer replacements, less downtime, and greater operational security. This is a critical point for any long-term infrastructure project.

What materials are needed for desalination?

A plant is a complex system, not just pipes. Using wrong materials in key components can cause system-wide failures. A complete titanium solution ensures every part works together seamlessly.

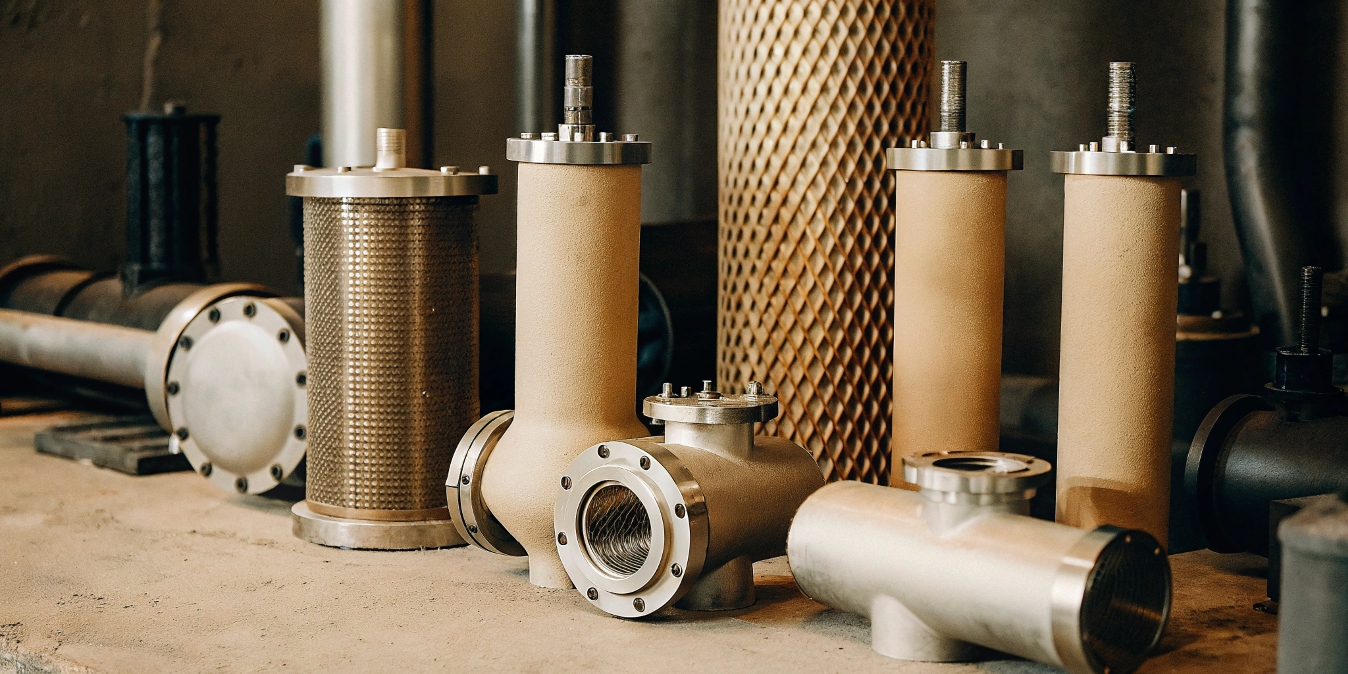

Desalination plants need more than just pipes. They require titanium alloy heat exchangers, corrosion-resistant pump housings, and robust filtration screens. We supply complete titanium solutions that cover all these critical components, ensuring system-wide longevity and reducing frequent equipment replacements.

When I work with Lisa, she needs a bill of materials that covers the entire fluid path. It’s not enough to just specify titanium for the tubes. Every component exposed to corrosive seawater or brine needs careful consideration.

Core Titanium Components

Beyond the main piping, several other parts are critical. We produce these components to the same high standards to ensure the integrity of the entire system.

Heat Exchangers

In thermal desalination, heat exchangers are vital. They handle hot brine and steam. Titanium tubes inside these units prevent corrosion and ensure efficient heat transfer for the plant’s lifetime. A failure here would be catastrophic.

Pump Housings and Impellers

Pumps move massive volumes of seawater and brine. Standard materials would corrode and erode quickly under this load. Titanium pump components maintain their shape and integrity, preventing costly pump failures and ensuring consistent flow rates.

Filtration Systems

Intake screens and filters must withstand constant exposure to seawater. Titanium mesh and screens are perfect because they don’t corrode or degrade. This protects important downstream equipment from debris.

I recently helped one of Lisa’s clients in the Gulf region. They sourced a full package from us—tubes, heat exchanger plates, and pump internals. This unified approach simplified their procurement. It also guaranteed material compatibility across the entire plant and drastically reduced their long-term maintenance forecast.

What equipment is needed for desalination?

Looking at a plant diagram can be overwhelming. Not knowing what each piece of equipment does leads to poor material choices. Let’s simplify the key equipment and their needs.

Key equipment includes heat exchangers, pumps, evaporators, and pressure vessels. Titanium welded tubes are crucial for these components. They ensure safe and reliable operation under the high temperatures and high salinity found in both Multi-Stage Flash (MSF)1 and Reverse Osmosis (RO)2 plants.

For a product manager like Lisa, it is helpful to visualize the plant as a series of stages. Each stage has specific equipment with unique demands. Here’s a breakdown of the core machinery common in thermal desalination plants, where titanium is most critical.

Critical Equipment Breakdown

These are the large, expensive pieces of equipment that do the heavy lifting. Their performance relies completely on the quality of the materials inside them.

Evaporators and Condensers

These are often large vessels containing thousands of tubes. In MSF plants, hot brine flows through these tubes to flash into steam, which is then condensed back into fresh water. Titanium tubes are essential here. They handle the high temperatures and prevent corrosion that would contaminate the final product water.

Pressure Vessels

These containers hold fluids under high pressure, especially in Reverse Osmosis systems. While the vessels themselves might be made of other materials, the internal piping and connections often use titanium alloys for strength and corrosion resistance.

Here’s a simplified view of where titanium fits:

| Equipment | Function | Why Titanium is a Must |

|---|---|---|

| Evaporator | Flashes hot brine into vapor | Resists high-temperature brine corrosion |

| Condenser | Cools vapor to produce fresh water | Prevents leaks and product contamination |

| Brine Heater | Heats seawater before evaporation | Handles the highest temperatures and corrosion |

| High-Pressure Pump | Pressurizes water for RO | Resists high-pressure erosion and corrosion |

Understanding that this equipment’s reliability depends on the integrity of the tubes makes the value of titanium obvious. A single tube failure can shut down an entire unit, costing millions in lost production.

What are the two main techniques used in the process of desalination?

There isn’t just one way to desalinate water. Choosing materials without knowing the process can be a big mistake. Let’s look at the two main methods and their specific needs.

The two main desalination technologies are Multi-Stage Flash (MSF), a thermal process, and Reverse Osmosis (RO), a membrane process. We supply custom titanium welded tubes for both. Our materials meet the high demands for corrosion resistance in MSF and high-pressure strength in RO systems.

Lisa often has to specify parts for both types of plants, so we discuss the differences regularly. While both make fresh water from salt water, how they do it changes the material stresses.

Multi-Stage Flash (MSF) Distillation

This is a thermal process. Think of it like boiling water at a lower temperature by reducing pressure. Seawater is heated and passed through a series of chambers, or stages. Each stage is at a lower pressure than the last. In each stage, some of the water "flashes" into steam, leaving the salt behind. The steam is then cooled and collected as fresh water. Titanium is critical here for the condenser and brine heater tubing. This is because of the high temperatures and extremely corrosive hot brine. Titanium Grade 2 is the workhorse material for MSF plants.

Reverse Osmosis (RO)

This is a membrane process. It uses high pressure to force seawater through a special membrane that blocks salt and other impurities. The main challenge here is the immense pressure, which can be over 60 bar (900 psi). The process is not as hot as MSF. However, the high-pressure pumps, valves, and piping on the brine side need materials that are both strong and corrosion-resistant. This is where higher-strength titanium alloys can be beneficial. They ensure the system does not fail under constant high pressure.

Conclusion

In summary, titanium welded tubes are the best choice for desalination. They provide unmatched corrosion resistance and strength, ensuring long-term reliability for all major equipment and processes.