Worried if the metal you sourced is genuine? Using fake titanium risks product failure and safety, but there are simple ways to check if your material is the real deal.

To tell if titanium is real, the best methods include checking that it is non-magnetic1 and testing its density. For absolute certainty, professional XRF analysis2 and certified Mill Test Reports (MTRs)3 are necessary to verify its exact chemical composition4 and authenticity.

These simple checks are a good starting point, but they only scratch the surface. If you’re like Emily, a sourcing specialist for a medical implant company I work with, you know that true confidence comes from understanding the details. Let’s explore the specific questions you need answered to ensure your material is genuine and meets strict industry standards.

How do you know if titanium is real?

Worried about counterfeit metals in your supply chain? Fake titanium can compromise your products and reputation. Here are the key signs to look for in authentic titanium material.

You know titanium is real by checking its physical properties. It’s lightweight but very strong, has a distinct dull grey color, and is non-magnetic. For mission-critical applications, always rely on certified material test reports from your supplier for absolute certainty.

I often tell my clients, like Emily, that you cannot rely on just one test. A multi-step verification process is the best practice. You should start with the basics. Titanium has a unique feel to it; it is much lighter than steel but feels stronger and more rigid than aluminum. Its color is a dull, silvery-grey, not shiny like polished stainless steel or chrome. But these are just observations. For my work in medical devices, we need definitive proof. That is where professional methods are essential. We use X-ray fluorescence (XRF) analyzers for a precise chemical breakdown. This is a non-destructive test that instantly confirms the alloy composition, showing us if it’s the correct Ti-6Al-4V ELI we need. It’s the same technology used in the aerospace industry for quality control. You should always demand a Mill Test Report (MTR) that shows the specific chemical and mechanical properties. This documentation provides full traceability back to the original material batch, which is a non-negotiable requirement for medical implants.

Will a magnet stick to titanium?

Using the wrong metal can be a costly mistake that leads to production delays. A simple magnet test can save you a lot of trouble. But is it a reliable way to identify titanium?

No, a magnet will not stick to pure titanium or the most common titanium alloys. Titanium is paramagnetic, which means it is effectively non-magnetic. If a strong magnet sticks firmly, you are likely dealing with another metal like stainless steel.

The magnet test is my go-to recommendation for a quick field check. When a client like Emily receives a new shipment of titanium rods, I tell them to grab a strong magnet, like a neodymium magnet. Pure titanium, such as our Grade 2 material, and key alloys like Ti-6Al-4V ELI are not magnetic. You might feel a very, very slight interaction if you use a very powerful magnet, but it will not stick. This simple action helps you immediately rule out ferromagnetic materials, which includes many grades of stainless steel. But you must be careful. Some specialty stainless steels and aluminum are also non-magnetic. So, this test is a great first screening tool, but it is not the final confirmation. I have seen cases where a supplier’s shipment was mixed. Some bars were titanium, and others were stainless steel. A quick magnet sweep of the entire batch can catch these mix-ups before they enter your production line. It’s a simple, low-cost quality assurance step that can prevent major issues down the road.

How do you test for titanium identification?

You need absolute certainty about your material’s identity. Guesswork isn’t an option in high-stakes industries like medical device manufacturing. So what are the professional tests that guarantee you have real titanium?

For professional titanium identification, use an XRF analyzer to confirm its exact chemical composition. You can also perform a density test, as titanium’s density is a unique ~4.5 g/cm³. For the highest assurance, always review the certified Mill Test Report (MTR).

When we certify our medical-grade titanium at Shaanxi Titonest Metal, we use a combination of tests to provide complete confidence. This is crucial for clients like Emily, who must meet strict FDA regulations. Here’s a breakdown of the common methods, from simple to complex.

Common Identification Tests

| Test Method | Description | Reliability |

|---|---|---|

| Magnet Test | A strong magnet will not stick to commercially pure titanium or most alloys. | Good (for initial screening) |

| Visual & Density Check | Titanium is dark grey and light for its strength. Its density is about 4.51 g/cm³, much less than steel’s ~7.85 g/cm³. | Fair (can be deceptive) |

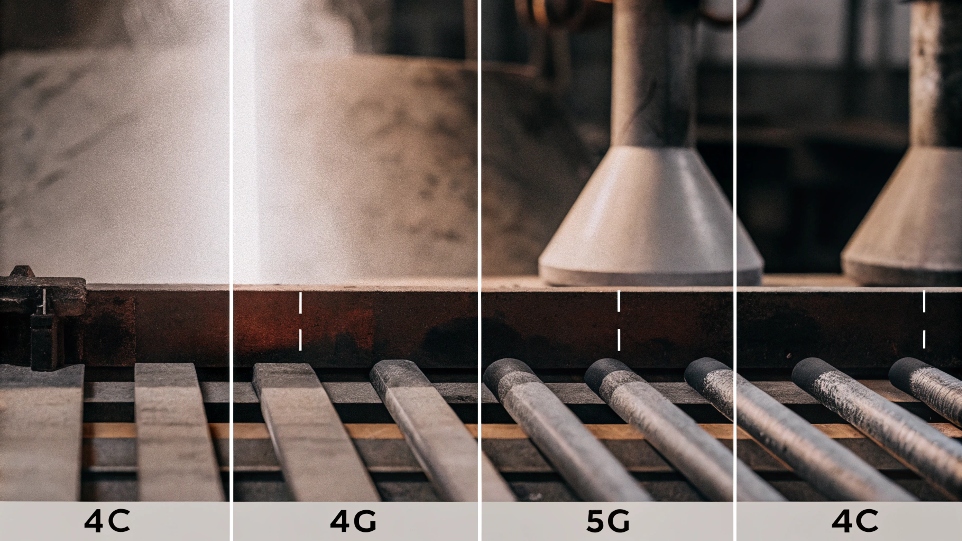

| Spark Test | Grinding titanium on a wheel produces a stream of brilliant, dense white sparks. This is a destructive test and requires experience. | Fair (requires safety gear) |

| XRF Analysis | Uses a handheld XRF gun to provide an exact elemental breakdown of the alloy without damaging the material. | Excellent (non-destructive, highly accurate) |

For Emily’s team and any medical application, only XRF analysis and certified MTRs meet their stringent requirements. The MTR is critical because it connects the physical material to its tested chemical and mechanical properties, ensuring it meets standards like ASTM F136 or ISO 5832-3.

Is there fake titanium?

The global materials market is filled with risks. Could you unknowingly be buying counterfeit titanium? The answer might surprise you and could seriously impact your entire production process and product safety.

Yes, fake or counterfeit titanium absolutely exists in the market. It is often substituted with cheaper materials like specific grades of stainless steel or even coated aluminum alloys. This is why strict supplier vetting and demanding full, traceable certification is critical.

I have seen this problem firsthand. A few years ago, a potential client came to us after experiencing a series of critical failures in their components. Their previous supplier had sold them "titanium" that was actually a lower-grade stainless steel. It looked similar enough to pass a quick visual inspection, but it failed in application. This represents a huge risk, especially in the medical field where biocompatibility and fatigue strength are paramount. Counterfeit material often comes with falsified paperwork, making it even harder to detect. This is why sourcing specialists like Emily are so diligent. We combat this threat by providing complete transparency. Our MTRs are tied to each specific batch and heat number. This creates an unbroken chain of custody from the initial titanium sponge to the final product we deliver. When you are sourcing, especially for critical applications, never choose a supplier based on price alone. Ask for their quality control procedures, their ISO 9001 certification, and examples of their traceability documentation. A reputable supplier will always be happy to provide this information.

Conclusion

Verifying titanium is a multi-step process. Combine simple physical tests with professional XRF analysis and always demand certified documentation. This ensures material authenticity and protects your products and patients.

-

Discover the significance of titanium’s non-magnetic properties in material verification. ↩

-

Explore how XRF analysis provides accurate metal identification without damaging the material. ↩

-

Learn why MTRs are crucial for ensuring material authenticity and traceability. ↩

-

Explore methods to verify the chemical composition of titanium for quality assurance. ↩