Do frequent material failures cause costly downtime? This constant replacement cycle hurts your bottom line. Grade 7 titanium pipes offer a reliable, long-term solution for harsh environments.

Yes, if your project involves highly corrosive environments. Grade 7’s palladium content1 provides superior resistance to acids and crevice corrosion. It’s ideal for chemical processing, desalination, and offshore applications where other grades might fail, ensuring long-term reliability and safety.

So, you see that Grade 7 is a powerful choice. But knowing when and why to use it is key to convincing your clients. It’s not just about the material itself; it’s about understanding its specific strengths and how they solve real-world problems. Let’s explore the applications where this alloy truly shines and why it’s the preferred option for engineers facing the toughest challenges. We will dive into the details that matter most.

What Are the Main Applications of ASTM B338 Grade 7 Titanium Pipes and Tubes?

Unsure where Grade 7 titanium fits best? Recommending it for the wrong use case can hurt your credibility. Understand its prime applications to guide your clients with confidence.

Grade 7 titanium tubes are mainly used in chemical processing equipment, especially heat exchangers, condensers, and chlor-alkali systems2. Their excellent corrosion resistance makes them essential for handling oxidizing media like nitric or hydrochloric acid, preventing costly failures in harsh industrial settings.

When I talk to technical buyers, they often ask where Grade 7 proves its worth. It’s not an all-purpose grade; it’s a specialist. We supply it for the most demanding jobs where other materials would quickly degrade. I remember a client in Europe who was constantly dealing with pitting failures in a chlorine drying tower. They were using Grade 2 tubes, which are good, but not for that specific, highly corrosive environment. After they switched to our Grade 7 tubes, the problem was solved completely. This is a perfect example of its value. It excels in applications exposed to aggressive media where reliability is not just preferred, but essential for safety and operational continuity.

Common Industrial Uses

| Application | Industry | Key Benefit |

|---|---|---|

| Heat Exchangers & Condensers | Chemical Processing | Resists oxidizing acids and chlorides |

| Chlor-Alkali Systems | Chemical Manufacturing | Prevents pitting in chlorine environments |

| Desalination Plants | Water Treatment | Immune to saltwater corrosion |

| Chemical Reactors | Petrochemical | Maintains integrity in aggressive media |

Why Is ASTM B338 Grade 7 Titanium Alloy Preferred in Certain Industries?

Struggling to explain the specific advantages of Grade 7 over other grades? This hesitation can weaken your sales pitch. The key is in its unique palladium-stabilized chemistry.

Grade 7 is preferred for its enhanced crevice corrosion resistance in reducing acids and chloride-rich environments, thanks to its palladium content. This makes it superior to Grade 2 in applications like offshore oil and gas, where exposure to brine and sour gas is common.

The secret to Grade 7’s performance is a small but critical addition: palladium. This element stabilizes the alloy, giving it exceptional resistance to crevice corrosion. This is especially true in hot, salty, or acidic conditions where even Grade 2 might struggle. Sophie, a technical sales rep I work with, often has to explain this to her clients in the offshore oil and gas sector. They deal with brine and hydrogen sulfide daily. I shared a story with her about one of our Gulf projects. They switched the tubing in a subsea cooling unit from Grade 2 to Grade 7. The result? They doubled the system’s service life. That’s a powerful and easy-to-understand benefit for any purchasing manager. It translates directly to lower maintenance costs and greater operational uptime.

Grade 7 vs. Grade 2: Key Differences

| Feature | Grade 7 (ASTM B338) | Grade 2 |

|---|---|---|

| Key Alloying Element | 0.12-0.25% Palladium | Commercially Pure |

| Crevice Corrosion | Excellent Resistance | Moderate Resistance |

| Best Use Case | Reducing acids, high-chloride media | Mildly oxidizing environments |

| Cost | Higher | Lower |

How Can You Choose Titanium Pipes and Tubes That Meet ASTM B338 Standards?

Worried about sourcing materials that don’t meet strict ASTM standards? Non-compliance can cause major project setbacks. The key is demanding certifiable proof and full traceability from your supplier.

Choose a supplier that provides full traceability from sponge to final product, backed by ISO 9001 certification. Insist on seeing mill test reports (MTRs) that confirm compliance with ASTM B338 standards for chemical composition, mechanical properties, and required testing.

At our facility, we treat ASTM B338 compliance as non-negotiable. It’s not just a stamp on a paper; it’s a process we live by. From the moment the raw titanium sponge arrives, we track everything. This full traceability is certified under ISO 9001 and GB/T 19001, which is a big deal for clients in regulated industries. When a purchasing manager asks how we guarantee our Grade 7 tubes meet the standard, I show them our reports. We provide detailed digital reports for every batch. These reports include spectrometer data showing the exact trace elements. This proves that the material is consistent and conforms perfectly to the standard. It gives them the confidence they need to sign off on a purchase order, knowing the material is fully compliant.

Your ASTM B338 Compliance Checklist

- Full Traceability: Ask for documentation tracing the material from raw sponge to the finished tube.

- Certifications: Verify the manufacturer holds current ISO 9001 or equivalent quality management system certifications.

- Material Test Reports (MTR): Insist on an MTR for your specific batch, detailing chemical composition and mechanical properties.

- Mandatory Tests: Confirm that tests like flattening, flaring, and hydrostatic pressure have been performed and passed.

How to Ensure Quality and Precision in ASTM B338 Grade 7 Titanium Pipes and Tubes?

Are you concerned about tube dimensions and tolerances? Even small inaccuracies can cause big problems during installation. The solution lies in choosing a supplier with end-to-end process control.

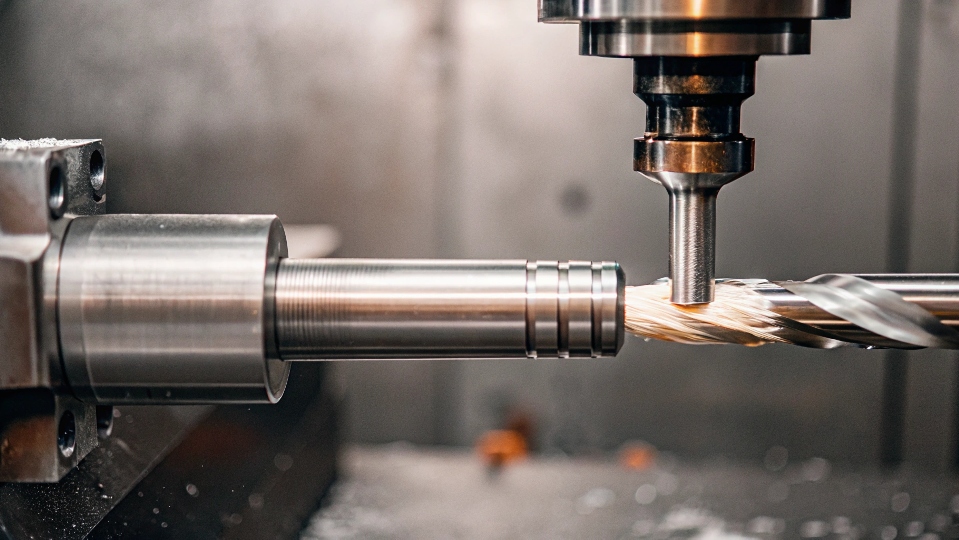

Ensure quality by partnering with a manufacturer that controls the entire production process in-house, from cutting and annealing to machining. Look for tight tolerance guarantees (e.g., ±0.2mm) and advanced inspection methods like eddy current and ultrasonic testing3 to detect any hidden defects.

Quality isn’t just about the raw material; it’s about how the tube is formed. Precision is everything. We control every step in-house, from the initial water cutting and annealing to the final CNC machining. This gives us total command over the final dimensions, allowing us to meet tight tolerances like ±0.2mm. Recently, a Canadian petrochemical client needed 9-meter-long Grade 7 pipes for a high-vacuum heat exchanger. Their main concern was ovality—the pipe had to be perfectly round. We guaranteed and delivered pipes with less than 3% ovality, which was critical for their system’s efficiency. We achieve this by using non-destructive testing on every single tube. Eddy current and ultrasonic inspections let us see any imperfections that the naked eye would miss, ensuring ultimate reliability.

Key Quality Control Steps

| Process Step | Control Method | Customer Benefit |

|---|---|---|

| Forming & Bending | In-house CNC machining | High precision, meets tight tolerances |

| Heat Treatment | Controlled annealing furnace | Uniform mechanical properties |

| Final Inspection | Eddy current & ultrasonic testing | Defect-free, reliable performance |

| Dimensional Checks | Digital calipers, laser measurement | Guaranteed fit and minimal ovality |

Conclusion

In summary, Grade 7 titanium tubes offer superior corrosion resistance. Choosing a certified supplier with strict quality control is key to harnessing its full potential for your most demanding projects.