Worried about equipment failing from severe corrosion? These failures are costly and halt operations. Grade 7 titanium1 offers superior protection where other metals simply dissolve.

Yes, if your project involves harsh acidic or chloride environments. Grade 7 titanium (UNS R52400) is a commercially pure grade alloyed with palladium2. This addition makes it the most corrosion-resistant titanium alloy, especially against crevice corrosion, making it ideal for chemical processing and marine uses.

I remember working with a client, Ahmed, who runs a distribution business in Turkey. He was looking for a reliable material for his customers in the chemical processing industry. He asked me, "What makes Grade 7 so special, and is it worth the cost?" It’s a great question. Understanding the specifics of different titanium grades is key to making a smart investment. To really get it, we need to break down what Grade 7 is and how it compares to other options.

What is grade 7 titanium?

Unsure what makes Grade 7 titanium unique? Choosing incorrectly means wasting money on unneeded features or risking failure. Here’s a clear breakdown of this powerful alloy.

Grade 7 titanium (UNS R52400) is a commercially pure titanium with a small amount of palladium (0.12-0.25%) added. This addition gives it the best corrosion resistance of all titanium alloys, especially in acidic environments where crevice corrosion is a major risk.

At its heart, Grade 7 is very similar to Grade 2 titanium in terms of mechanical properties. They are both classified as ‘commercially pure’ (CP). The magic ingredient is the small addition of palladium. This element acts as a catalyst, dramatically improving the material’s ability to resist corrosion, especially in reducing acids and chloride-rich environments.

Key Properties of Grade 7 Titanium

This isn’t about making the metal stronger, like in aerospace alloys. It’s about making it tougher against chemical attacks. I often explain this to clients like Ahmed by comparing it to a high-performance raincoat. Grade 2 is a standard raincoat; it keeps you dry in normal rain. Grade 7 is a specialized one for hurricanes. It costs more, but in a storm, it’s the only thing that works. The palladium helps the protective oxide layer on the titanium reform instantly, even in aggressive chemical environments that would overwhelm lesser materials.

Let’s look at a simple breakdown:

| Property | Description | Common Application |

|---|---|---|

| Composition | Titanium + 0.12-0.25% Palladium | Chemical reactors, Heat exchangers |

| Primary Advantage | Exceptional crevice corrosion resistance | Marine hardware, Desalination plants |

| Mechanical Strength | Similar to Grade 2 (Moderate) | Anywhere Grade 2 might fail from corrosion |

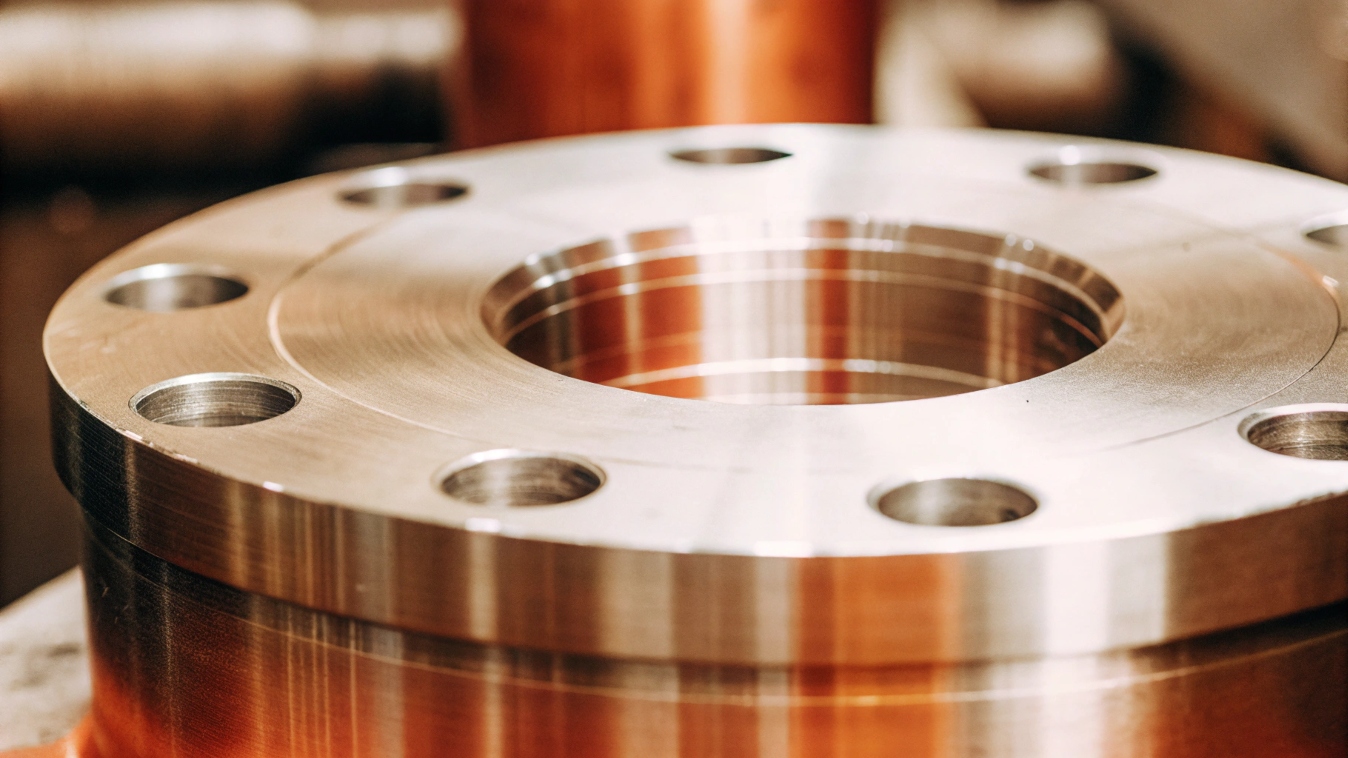

This targeted performance is why my partners and I often manufacture custom Grade 7 parts like heat exchanger tubes and reaction vessels for the chemical processing industry. It’s truly a problem-solver alloy.

What is the most expensive grade of titanium?

Worried about the high cost of titanium? Not all grades are priced the same, and picking the wrong one can blow your budget. Let’s look at why certain grades are more expensive.

Grade 7 and Grade 23 (the high-purity medical version of Grade 5) are often the most expensive. Grade 7’s high cost comes from the palladium, a precious metal. Grade 23’s cost is due to the strict purity requirements for medical implants.

The price of titanium isn’t just about the base metal. It’s driven by the alloying elements and the manufacturing process. When Ahmed was looking to stock materials for his business, price was a huge factor for his profitability. I had to explain that while Grade 7 is expensive, its price is justified by its performance in specific, high-value applications where failure is not an option.

Factors Driving Titanium Grade Costs

The biggest cost driver for Grade 7 is palladium. Palladium is a precious metal, part of the platinum group, and its market price is very high. Adding even a tiny amount (0.12-0.25%) significantly increases the raw material cost. On top of that, the melting process to ensure the palladium is evenly distributed throughout the titanium is more complex and requires more precise control at our manufacturing facilities.

For other grades like Grade 23 (6Al-4V ELI), the cost comes from process control. It’s used for things like surgical implants, so it must be extremely pure (ELI stands for Extra-Low Interstitials). This requires multiple melting stages and rigorous testing, which adds to the final price.

| Grade | Main Cost Driver | Why it’s Expensive |

|---|---|---|

| Grade 7 | Palladium (Precious Metal) | High raw material cost of the alloying element. |

| Grade 23 | Purity & Process Control | Strict manufacturing standards for medical use. |

| Grade 5 | Alloying & Processing | Most common alloy, but more complex than CP grades. |

| Grade 2 | Commodity Pricing | Most common CP grade, relatively low cost. |

So, while Grade 7 is on the high end, you’re paying for a specific, powerful feature: unmatched corrosion resistance that protects critical assets.

What is the difference between Grade 2 and Grade 7 titanium?

Can’t decide between Grade 2 and Grade 7 titanium? They look and feel similar, but choosing wrong leads to rapid failure in critical applications. Let’s clarify the key difference that matters most.

The main difference is palladium. Grade 2 is commercially pure titanium. Grade 7 is essentially Grade 2 with 0.12-0.25% palladium added. This small addition makes Grade 7 far more resistant to crevice and acidic corrosion, where Grade 2 would fail.

This is one of the most common questions I get from procurement teams and distributors like Ahmed. On paper, their mechanical properties—strength, ductility, and formability—are almost identical. You can bend, weld, and machine them in very similar ways. The difference is purely chemical and becomes obvious under pressure.

Performance in Corrosive Environments

Think about a gasketed flange joint in a pipe carrying warm saltwater or a mild acid. In the tiny gap, or crevice, between the flange and the gasket, oxygen can get depleted. For Grade 2, this situation can lead to crevice corrosion, where the metal starts to break down in that specific spot. Grade 7, with its palladium content, resists this attack completely. I recently helped a client source Grade 7 tubing for a petrochemical heat exchanger. They had previously used Grade 2, which failed in less than a year due to crevice corrosion. The Grade 7 replacement has been running without issue, preventing costly downtime.

Here’s a clear comparison to guide your decision:

| Feature | Grade 2 Titanium | Grade 7 Titanium |

|---|---|---|

| Composition | Commercially Pure Titanium | Commercially Pure Ti + Palladium |

| Strength | Moderate | Moderate (Similar to Gr 2) |

| Best For | General corrosion resistance | Severe crevice & acidic corrosion |

| Weakness | Susceptible to crevice corrosion | Higher cost |

So, the choice is simple: for general use in mildly corrosive environments, Grade 2 is cost-effective. For aggressive atmospheres prone to crevice corrosion, Grade 7 is a necessary investment in reliability.

What is the difference between titanium and titanium alloy?

Are "titanium" and "titanium alloy" the same thing? Using the terms interchangeably can lead to ordering the wrong material for your needs, causing project delays or failures. Let’s quickly define the difference.

"Titanium" usually refers to commercially pure (CP) grades, like Grade 2 or Grade 7. They are over 99% titanium and valued for corrosion resistance. "Titanium alloys," like Grade 5, have other elements like aluminum and vanadium added to significantly boost strength and hardness.

These terms are often used loosely in conversation, but in my world of supply chain consulting and manufacturing, the distinction is critical. Getting this right is fundamental for any distributor or engineer. When my manufacturing partners receive an order, the material specification is the most important instruction on the page.

Pure Grades vs. True Alloys

Commercially Pure (CP) titanium grades are numbered 1 through 4, with Grade 7 being a special palladium-enhanced version of Grade 2. Their main feature is an incredible natural resistance to corrosion. This comes from a stable, protective oxide layer that forms on the surface. They are not particularly strong, but they are very ductile and easy to form. Think of them as champions of chemical defense, perfect for chemical processing equipment.

Titanium alloys, on the other hand, are engineered for mechanical performance. The most famous is Grade 5 (Ti-6Al-4V), which has 6% aluminum and 4% vanadium. These additions make it much stronger and harder than pure titanium, but they slightly reduce its general corrosion resistance. This is why alloys are the top choice for high-strength, lightweight parts in aerospace and performance automotive applications.

| Category | Key Benefit | Typical Grades | Common Use Case |

|---|---|---|---|

| Pure Titanium | Superior Corrosion Resistance | Grade 1, 2, 7 | Chemical Processing, Marine Hardware |

| Titanium Alloys | High Strength-to-Weight Ratio | Grade 5, 23 | Aerospace Structures, High-Stress Bolts |

Choosing between them depends entirely on your priority: are you fighting against chemical attack or high physical stress?

Conclusion

Grade 7 titanium is a premium solution for extreme corrosion. Its high cost, due to palladium, is an investment in reliability for harsh chemical and marine applications.