Are you choosing metals based on old myths? This can lead to costly mistakes. Let’s separate fact from fiction and find the right material for your project’s success.

No, titanium is not the strongest metal. Some metals like tungsten1 have higher tensile strength. However, titanium’s incredible strength-to-weight ratio and corrosion resistance make it one of the most useful and versatile high-performance metals available for demanding applications.

Understanding this difference is key to smart procurement. Many people think "strongest" is the only thing that matters, but that’s rarely true. In my 12 years of consulting, I’ve seen how focusing on the right properties saves my clients money and improves their products. We will explore how titanium compares to other materials. This will help you make informed decisions, whether you’re building aerospace components or stocking inventory like my client Ahmed in Turkey. Let’s start with the metal that actually holds the title for pure strength.

What is the strongest metal in the world?

Choosing a metal based on strength alone can lead to failure. Your project might end up too heavy, too brittle, or far too expensive. Let’s discuss true strength.

The strongest pure metal by tensile strength is tungsten. It is incredibly dense and has a very high melting point. For this reason, it is used in very specific, high-temperature applications. Other metals, like chromium, are also extremely hard and strong.

It is important to look beyond a single number on a spec sheet. Absolute strength isn’t the same as practical, usable strength. Tungsten is a perfect example. Yes, it has the highest tensile strength, but it’s also extremely heavy and dense. It can be brittle at lower temperatures, which makes it unsuitable for many structural parts. This is where titanium alloys like Grade 5 (Ti-6Al-4V) become so valuable. I recently advised an aerospace client who needed a material for a critical landing gear component. Tungsten was strong enough, but it was far too heavy. The extra weight would increase fuel consumption over the aircraft’s life. Steel was an option, but it lacked the necessary corrosion resistance. We chose Titanium Grade 5. It provided the required strength for landing stresses but was nearly 45% lighter than the steel alternative. This is the power of the strength-to-weight ratio. It’s not about finding the strongest metal, but the smartest one for the job.

Strength vs. Density Comparison

| Metal | Tensile Strength (approx. MPa) | Density (g/cm³) | Key Benefit | Key Drawback |

|---|---|---|---|---|

| Tungsten | 1510 | 19.3 | Highest Strength | Very Heavy, Brittle |

| Chromium | 415 | 7.19 | Very Hard, Resists Wear | Often used as a plate |

| Titanium (Grade 5) | 950 | 4.43 | High Strength-to-Weight | Higher Initial Cost |

| Steel (Alloy) | 760 | 7.85 | Cost-Effective, Versatile | Heavy, Prone to Rust |

Is titanium stronger than diamond?

Confusing a material’s hardness with its strength can be a big mistake. You might choose a material that seems tough but actually shatters easily under sudden impact or stress.

No, diamond is much harder than titanium, but it is not stronger. Hardness is the ability to resist scratches, while strength or toughness is the ability to resist breaking. Titanium is far tougher and can handle impacts that would shatter a diamond.

Think about hardness and toughness this way. A ceramic plate is very hard. You cannot easily scratch it with a fork. But if you drop it, it will shatter into pieces. The plate is hard, but it is not tough. On the other hand, a car’s rubber tire is not very hard. You could easily scratch it with a sharp object. But it is very tough. It can absorb the shock of hitting potholes and curbs all day without breaking. This difference is critical in engineering. I work with many B2B companies that manufacture medical devices. One of them makes custom joint replacements. They need a material that is both safe for the body and extremely durable. A diamond is biocompatible, but far too brittle for this use. The shock from a simple jump could cause it to crack inside a patient. That’s why we use titanium alloys like Grade 23 for these implants. It has the perfect combination of strength, flexibility, and toughness to withstand millions of stress cycles from walking and running.

What is the toughest metal in the world?

Material failure in harsh settings costs a lot of time and money. Constant maintenance and parts replacement can stop your operations and hurt your bottom line. Let’s find a better way.

Titanium is a leading candidate for the toughest metal, especially when you consider its full range of properties. Toughness means resisting fracture. Titanium’s ability to handle impact, fatigue, and extreme corrosion makes it one of the most durable metals available.

Toughness is more than just resisting a single blow. True toughness includes durability over a long time, especially in a challenging environment. A material isn’t tough if it slowly gets weaker because of corrosion. This is where titanium really shines. I have a client who operates a large acid processing plant. They were using high-grade stainless steel pipes for their systems. But the aggressive chemicals forced them to replace entire sections every 3 to 5 years. The downtime and material costs were enormous. I worked with their procurement team to switch the entire system to Grade 2 titanium. The initial cost was higher, but they have now gone over a decade without a single corrosion-related failure. This is because titanium forms a protective oxide layer that instantly heals itself when scratched. This incredible resilience is a core part of its toughness. For a distributor like Ahmed, stocking Grade 2 titanium for marine and chemical clients is a smart strategy because of this exact long-term reliability.

What is the strongest material on Earth?

Are you chasing the "strongest material"? Often, these are lab curiosities. You need a material that you can actually source and use for your real-world projects today.

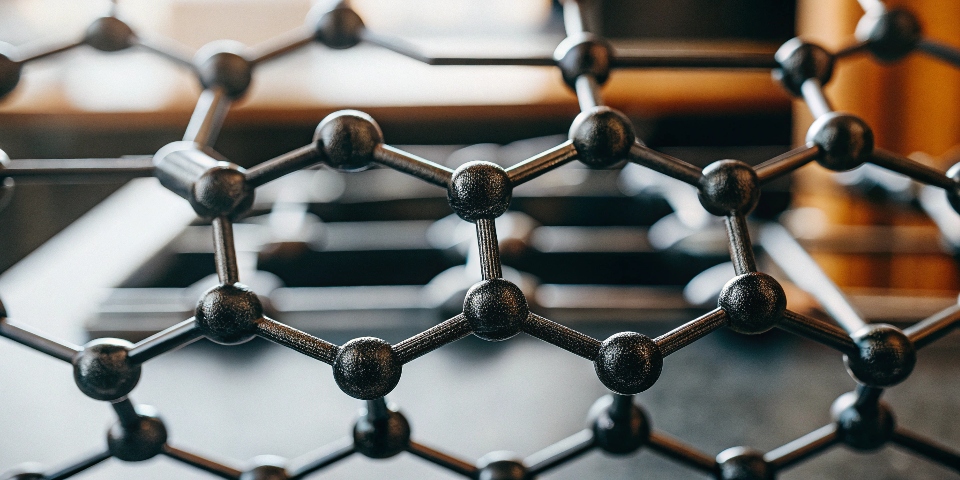

The strongest material ever tested is graphene, which is a single, one-atom-thick layer of carbon atoms. It is theoretically over 200 times stronger than steel. However, producing it in large, usable quantities is still extremely difficult and expensive today.

There is often a huge gap between a laboratory discovery and an industrial reality. Graphene is a true "supermaterial," but we can’t build ship hulls or airplanes with it yet. Engineers, designers, and procurement managers need solutions that are available on the market right now. This is why context is everything in material sourcing. For practical, high-performance applications, we have to look at what we can reliably manufacture and supply. Among all the commercially available metals, titanium offers one of the best all-around performance packages. It gives you high tensile strength, very low density, outstanding toughness, and unmatched corrosion resistance all in one. When an aerospace or medical device company comes to me for advice, they are not asking for a theoretical material. They ask for the best practical material for their critical application. And in most of those cases, a titanium alloy is the ideal solution. It is the material we can use to get the job done right now, safely and efficiently.

Conclusion

Titanium isn’t the single strongest metal. But its excellent strength-to-weight ratio, toughness, and corrosion resistance make it the superior choice for many of today’s most demanding applications.

-

Discover the various industrial applications of tungsten and its unique properties. ↩