Найти дорогостоящие, пользующиеся спросом товары непросто. Вы хотите развивать свой бизнес, но чувствуете, что застряли на низкорентабельных товарах. Это означает, что вы, возможно, упускаете выгодные нишевые рынки.

Стержень из титанового сплава медицинского класса - это высокоэффективный материал, используемый для изготовления имплантатов, таких как костные винты, суставы и зубные штифты. Он прочен, устойчив к коррозии и биосовместим, что делает его невероятно безопасным и надежным для использования внутри человеческого тела, особенно такие сорта, как Ti-6Al-4V ELI1.

Этот материал - не просто металл, а важнейший компонент современной медицины. Вы наверняка видели, как растет индустрия здравоохранения, и эти стержни занимают в ней центральное место. Для поставщика это не просто еще одна линейка продукции. Это точка входа в передовой, дорогостоящий мир медицинского производства. Давайте рассмотрим, как эта возможность выглядит для вашего бизнеса.

Что именно представляет собой стержень из титанового сплава медицинского класса?

Вы пытаетесь найти продукт, который не является товаром? Вы видите спрос на специализированные материалы, но не уверены, с чего начать. Это может привести к тому, что вы застрянете на высококонкурентных рынках.

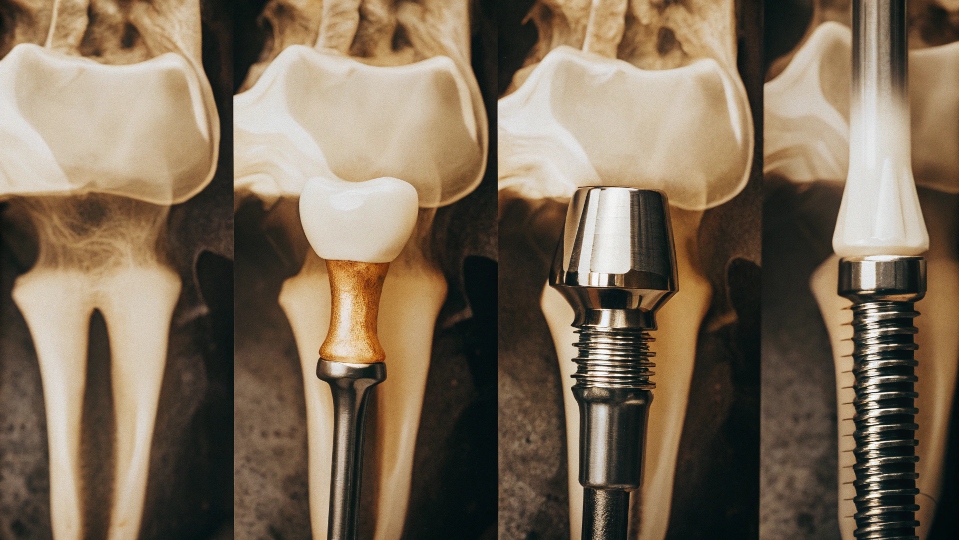

Медицинский стержень из титанового сплава - это специально разработанный металлический стержень, используемый для изготовления медицинских изделий. Обычно они используются для изготовления костных винтов, искусственных суставов и зубные имплантаты2. Его ключевыми характеристиками являются высокая прочность, отличная коррозионная стойкость и биосовместимость3Это означает, что он не наносит вреда человеческому организму.

Более глубокий взгляд на материал

Чтобы понять его ценность, необходимо рассмотреть детали. Наиболее распространенный тип, с которым вы можете столкнуться, это Ti-6Al-4V ELI (класс 23). Аббревиатура "ELI" означает "Extra Low Interstitials", что означает чрезвычайно низкий уровень содержания кислорода, углерода и азота в сплаве. Именно этот особый химический состав обеспечивает материалу превосходную вязкость разрушения и усталостную прочность, что делает его идеальным для долгосрочных имплантатов, которые должны выдерживать постоянные нагрузки.

Вот простой перечень его основных свойств:

| Недвижимость | Польза для медицинского использования | Почему это имеет значение для стокеров |

|---|---|---|

| Высокое соотношение прочности и веса | Имплантаты могут быть прочными, не громоздкими и не тяжелыми, что повышает комфорт пациента. | Это материал премиум-класса, который стоит дороже. |

| Отличная биосовместимость | Организм человека не отторгает его, предотвращая воспаления и аллергические реакции. | Это основная причина, по которой он относится к продуктам "медицинского класса" с особыми, не подлежащими обсуждению стандартами. |

| Превосходная коррозионная стойкость | Он не ржавеет и не разрушается под воздействием биологических жидкостей в течение многих лет. | Обеспечивает надежность продукции и снижает ответственность ваших клиентов - производителей устройств. |

| Немагнитный | Пациенты с титановыми имплантатами могут спокойно проходить МРТ-сканирование. | Это ключевой момент, на который обращают внимание производители устройств. |

За десять лет работы в этой области я могу сказать, что постоянство - это все. Производители медицинского оборудования не могут позволить себе отклонения от партии к партии. Именно поэтому такие стандарты, как ASTM F1364 это не просто рекомендации, это строгие правила. Когда производитель покупает удилище, сертифицированное по этому стандарту, он приобретает уверенность в том, что оно будет работать именно так, как ожидается.

Кто покупает медицинские титановые стержни и где на них спрос?

Вы беспокоитесь о том, что на складе не найдется ни одного покупателя? Вы видите нишу рынка, но не уверены в ее размере и потенциале. Эта неуверенность может стоить вам больших возможностей для роста.

Основными покупателями являются производители медицинского оборудования, поставщики стоматологических лабораторий и бренды хирургических инструментов. Ключевыми рынками являются страны с высокими медицинскими стандартами, такие как США, Германия, Япония и Бразилия. Спрос растет во всем мире в связи со старением населения и более частыми операциями.

Понимание своих будущих клиентов

Спрос на эти стержни не случаен, он обусловлен очень специфическими потребностями в сфере здравоохранения. Вашими основными клиентами будут компании, имеющие станки с ЧПУ и другое точное оборудование. Они покупают эти стержни в качестве сырья, а затем обрабатывают их в готовые медицинские изделия.

Вот кому вы будете продавать:

- Производители ортопедических имплантатов: Эти компании производят ножки для тазобедренных суставов, костные пластины, кейджи для спинальной хирургии и винты для фиксации переломов. Они являются крупнейшими потребителями и требуют материалов, соответствующих самым строгим стандартам, таким как ASTM F136.

- Поставщики зубных имплантатов: Это огромный и растущий рынок. Они используют титановые стержни меньшего диаметра для создания штифтов для зубных имплантатов и абатментов. Здесь востребованы как высокая точность, так и эстетическая совместимость.

- Производители хирургических инструментов: Хотя многие инструменты изготавливаются из нержавеющей стали, некоторые высококлассные или специализированные инструменты, например, некоторые ретракторы или щипцы, изготавливаются из титана благодаря его легкому весу и прочности.

- Компании, производящие сердечно-сосудистые устройства: Подумайте о корпусах кардиостимуляторов и компонентах для искусственных сердечных клапанов. Для этих применений необходима абсолютная надежность и коррозионная стойкость титана.

Работая с клиентами из этих отраслей, я заметил четкую тенденцию. Многие из них отказываются от хранения больших запасов сырья. Они предпочитают работать с надежными поставщиками, которые могут обеспечить доставку точно в срок. Это сокращает их капитальные затраты и складские площади. Как складской оператор, вы заполняете этот критический пробел в цепочке поставок.

Почему вы должны иметь в своем арсенале медицинские титановые стержни?

Ваши текущие запасы заполнены низкорентабельными и высококонкурентными товарами? Вы ищете что-то, что обеспечит более высокую прибыль и выделит вас из толпы. Придерживаясь стандартных товаров, вы ограничиваете свою рентабельность.

Вы должны иметь на складе медицинские титановые стержни, потому что они являются высокоценным, стандартизированным продуктом, идеально подходящим для распространения. Глобальные стандарты, такие как ASTM F136, снижают ваши риски, поскольку материал является общепризнанным. Это позволит вам войти в прибыльную цепочку поставок медицинских товаров высокого класса.

Деловое обоснование для складирования титана

Добавление медицинского титана в ваши запасы - это стратегический шаг, а не просто добавление продукта. Это позиционирует вашу компанию в совершенно другой лиге. Барьеры для входа на рынок выше, чем для общепромышленных металлов, а значит, конкуренция ниже и маржа выше.

Вот почему это имеет смысл с точки зрения бизнеса:

- Высокая ценность, высокая рентабельность: Это не сыпучий товар. Цена за килограмм значительно выше, чем у стали или алюминия, из-за сложного производственного процесса и строгого контроля качества. Это напрямую отражается на рентабельности ваших инвестиций.

- Стандартизация снижает риск: Этот продукт регулируется такими мировыми стандартами, как ASTM F136 и ISO 5832-3. Пруток Grade 23, сертифицированный по этим стандартам, одинаков, где бы вы его ни продавали - в США, Германии или Корее. Это означает, что ваши запасы не устареют из-за изменений региональных спецификаций.

- Ворота в индустрию премиум-класса: Имея на складе этот материал, вы становитесь поставщиком индустрии медицинского оборудования. Это стабильный, растущий и устойчивый к рецессии сектор. Вы налаживаете отношения с высококачественными клиентами, для которых надежность важнее чистой стоимости.

- Простая логистика: Несмотря на свою высокую стоимость, титан не относится к категории опасных или вредных материалов. Это упрощает международные перевозки, таможенное оформление и складирование по сравнению с химикатами или другими регулируемыми товарами.

Я видел, как многие дистрибьюторы начинали работу с нами с малого, возможно, с нескольких наиболее распространенных диаметров. В течение года или двух они становятся основными местными поставщиками для начинающих и даже уже состоявшихся производителей медицинского оборудования. Это классический продукт для "входа в дверь" в очень прибыльную отрасль.

Что следует учитывать при импорте из Китая?

Вы не решаетесь импортировать продукцию из Китая из-за сомнений в качестве или надежности? Вы слышали истории о проблемах со связью и несовместимых продуктах. Эти опасения могут помешать вам получить доступ к крупному производственному центру.

При импорте из Китая проверьте наличие сертификатов, таких как ISO 9001, и отчетов об испытаниях материалов по стандарту ASTM F136. Спросите о сроках изготовления, минимальном количестве заказа (MOQ) и контроле качества, включая поддержку тестирования третьей стороной. Убедитесь, что они могут предоставить все таможенные документы.

Ваш контрольный список для поиска надежного китайского поставщика

Китайская "Титановая долина" в Баоцзи, где расположена моя компания, - это мировой центр производства титана. Здесь можно найти отличных поставщиков мирового класса, но нужно знать, о чем спрашивать.

Вот основные вопросы, которые вы должны задать любому потенциальному поставщику:

- Сертификация и документация:

- Вопрос: "Можете ли вы предоставить копию вашего сертификата ISO 9001? Можете ли вы показать мне образец протокола испытаний материала (MTR) для стержня Ti-6Al-4V ELI, который показывает полное химическое и механическое соответствие ASTM F136?"

- Почему это важно: Это не подлежит обсуждению. Без надлежащей документации материал бесполезен для применения в медицине.

- Контроль производства и время выполнения заказа:

- Вопрос: "Контролируете ли вы весь производственный процесс, от плавки слитка до окончательной отделки, своими силами? Или вы передаете некоторые этапы на аутсорсинг?"

- Почему это важно: Поставщик с полностью интегрированной производственной линией может предложить более стабильное качество и надежные сроки поставки. Задержки часто случаются, когда работа передается между разными заводами.

- Минимальное количество заказа (MOQ):

- Вопрос: "Какова ваша минимальная стоимость? Поддерживаете ли вы небольшие пробные заказы для новых клиентов?"

- Почему это важно: Как начинающий продавец, вы не хотите быть вынуждены закупать огромное количество товара. Хороший партнер будет гибким и поможет вам начать работу.

- Обеспечение качества:

- Вопрос: "Каков ваш процесс проверки качества? Проводите ли вы ультразвуковые испытания? Приглашаете ли вы сторонние инспекционные службы, такие как SGS или Bureau Veritas, для проверки материала перед отправкой?"

- Почему это важно: Уверенный в себе производитель всегда будет открыт для сторонних проверок. Это показывает, что им нечего скрывать.

- Экспорт документов:

- Вопрос: "Можете ли вы предоставить все необходимые документы для таможенного оформления, такие как сертификат происхождения, подробный упаковочный лист и коммерческий счет-фактуру, соответствующий сертификату на материал?"

- Почему это важно: По моему опыту, именно здесь у многих импортеров возникают проблемы. Небольшая ошибка в документах может привести к тому, что ваш ценный груз застрянет в порту на несколько недель, что сведет на нет всю экономию, на которую вы рассчитывали.

Выбор поставщика - это выбор партнера. Ориентируйтесь на их прозрачность, опыт и готовность поддерживать ваш бизнес, а не только на цену.

Готовы попробовать? Давайте начнем с малого

Выбор правильного поставщика - это большая ответственность. Вы хотите быть уверены, прежде чем размещать крупный заказ. Это разумный способ ведения бизнеса.

В компании Titonest Metal мы понимаем это. Мы находимся в Баоцзи, сердце китайской Титановой долины, и имеем более чем 20-летний опыт работы. Мы специализируемся на титановых стержнях медицинского класса, таких как Grade 23, и работаем со многими международными медицинскими клиентами. Поскольку у нас есть собственное оборудование для плавки, ковки, обработки и тестирования, мы контролируем весь процесс. Это означает стабильное качество и надежные графики для вас. Мы поддерживаем проведение испытаний третьей стороной и предоставляем все необходимые стандартные экспортные документы.

Мы верим в создание партнерских отношений, а это начинается с доверия. Мы рекомендуем новым клиентам начинать с небольшого пробного заказа. Это позволит вам воочию убедиться в нашем качестве и опробовать рынок с минимальным риском. Мы готовы помочь вам во всем процессе экспорта, начиная с таможенного декларирования и заканчивая консультациями по доставке.

Заключение

Титан медицинского назначения - это быстрорастущий и высокодоходный продукт. Выбрав надежного поставщика, который может предоставить сертифицированные материалы и полную документацию, вы сможете уверенно выйти на этот прибыльный рынок.

Готовы рассмотреть эту возможность? Свяжитесь со мной напрямую через WhatsApp или по электронной почте. Давайте получим предложение или образец в ваши руки и начнем наше сотрудничество.

-

Узнайте об этом особом титановом сплаве и его уникальных свойствах, которые делают его идеальным для использования в медицине. ↩

-

Узнайте о растущем спросе на титан в стоматологии и его преимуществах. ↩

-

Понимать важность биосовместимости для предотвращения побочных реакций у пациентов. ↩

-

Узнайте, как этот стандарт обеспечивает качество и безопасность при использовании титана в медицине. ↩