Are you struggling to explain titanium’s uses beyond the basics? You know it’s a super-metal, but need concrete examples. I’ll show you exactly where and why it is used.

Titanium is a critical material in aerospace, medical, chemical processing, and marine industries. Its unique combination of high strength, low density, and excellent corrosion resistance makes it the top choice for high-performance and demanding applications.

When I attend trade shows, I meet people like Sophie. She’s a technical sales rep who needs to explain these applications to her clients. She knows her customers need more than just a list; they need to understand why titanium is the right choice for their specific problem, whether it’s for an airplane part or a chemical tank. This is what we will explore together. Let’s look at the specific industries and products where our titanium makes a difference every day.

What are 10 uses of titanium?

Do you need to list titanium’s many uses? You know it’s versatile but need specific examples for a client. I can help you list the top ten applications easily.

Titanium’s top 10 uses are in aerospace, chemical plants, marine equipment, medical implants, energy production, automotive parts, defense hardware, sports gear, architecture, and consumer electronics. Each industry values its unique properties.

I often find that listing applications helps clients see the possibilities. At a trade show in Germany, a manager from a sporting goods company was amazed. He saw that the same high-strength titanium we supply for his golf clubs also goes into jet engine components. This versatility is titanium’s greatest strength. Let’s break down these ten areas to see how this metal performs.

High-Performance Industries

For industries where failure is not an option, titanium is the go-to material. In aerospace, it’s used for engine parts and structural frames. The chemical industry relies on it for corrosion-resistant pipes and reactors, a big part of what we manufacture. In the marine and defense sectors, its resistance to saltwater corrosion is essential for submarines and ships. The energy sector uses it in power plant turbines and geothermal wells.

Everyday and Specialized Applications

Titanium is also closer to us than we think. Medical implants like hip joints and dental fixtures use it because it’s biocompatible, meaning our bodies don’t reject it. High-performance cars use titanium for exhaust systems and engine valves to reduce weight. You can find it in high-end sports equipment like tennis rackets and bicycle frames. Architects even use it for building facades, like the Guggenheim Museum in Bilbao, for its durability and unique finish. Finally, it’s in premium laptops and smartphones for a strong, lightweight frame.

| Industry | Application Example | Key Titanium Property |

|---|---|---|

| Aerospace | Jet Engine Components | High Strength-to-Weight Ratio |

| Chemical | Reactors and Piping | Corrosion Resistance |

| Medical | Hip and Knee Implants | Biocompatibility, Strength |

| Sports | Golf Clubs, Bike Frames | Lightweight, Strong |

| Marine | Submarine Hulls | Saltwater Corrosion Resistance |

What are the common applications of titanium?

You know titanium is used everywhere. But you need to explain the most common uses to your clients. I will show you the key applications that everyone should know about.

The most common applications are aircraft structures, medical implants, chemical processing equipment, offshore marine hardware, and performance sports gear. Our ISO 90011 certified alloys are ideal for these demanding uses.

When Sophie explains this to her aerospace clients, she focuses on performance. She has to communicate why titanium is worth the investment. It’s not just about one feature, but the combination of features that makes it so common in certain fields. These applications share a need for materials that can perform under extreme stress without failing. Our company ensures this reliability through rigorous testing and certifications, which is why purchasing managers trust our products for these critical uses.

Why These Applications are Common

These applications have become common because no other metal offers the same package of benefits. Let’s look deeper.

- Aircraft Structures: For every kilogram of weight saved on an airplane, airlines save thousands of dollars in fuel over the plane’s life. Titanium has the strength of steel at about 45% less weight. This makes it a clear choice.

- Medical Implants: The human body is a corrosive environment. Many metals degrade inside the body or cause allergic reactions. Titanium is inert and biocompatible, so it integrates with bone and lasts for decades.

- Chemical Equipment: In a chemical plant, corrosion can lead to catastrophic failures. Titanium withstands harsh chemicals, especially chlorides, that destroy even high-grade stainless steels. This reliability prevents costly shutdowns and improves safety. We produce a lot of Grade 2 and Grade 7 piping for these exact situations.

This focus on reliability and performance under pressure is what connects these common uses.

What is the biggest use of titanium?

Are you wondering where most titanium goes? You might guess medical or sports. I will reveal the single largest industry that consumes titanium and explain why it’s so dominant.

The aerospace industry is the single biggest user of titanium. It is essential for jet engines, airframes, and landing gear because of its high strength-to-weight ratio and ability to withstand extreme temperatures.

At our company, the numbers speak for themselves. A large portion of our 3,500-ton annual capacity is dedicated to aerospace-grade titanium. When I meet with buyers from European and U.S. aerospace companies, their main concerns are always the same: quality certification and traceability. They need to know the exact history of every single plate or forging. This is because titanium’s role in an aircraft is absolutely critical. There is no room for error, and that is why this industry consumes so much of the highest-quality titanium available.

Why Aerospace Dominates

The primary reason is the intense performance demands of modern aircraft. Both commercial and military planes need to be lighter for fuel efficiency and faster for performance.

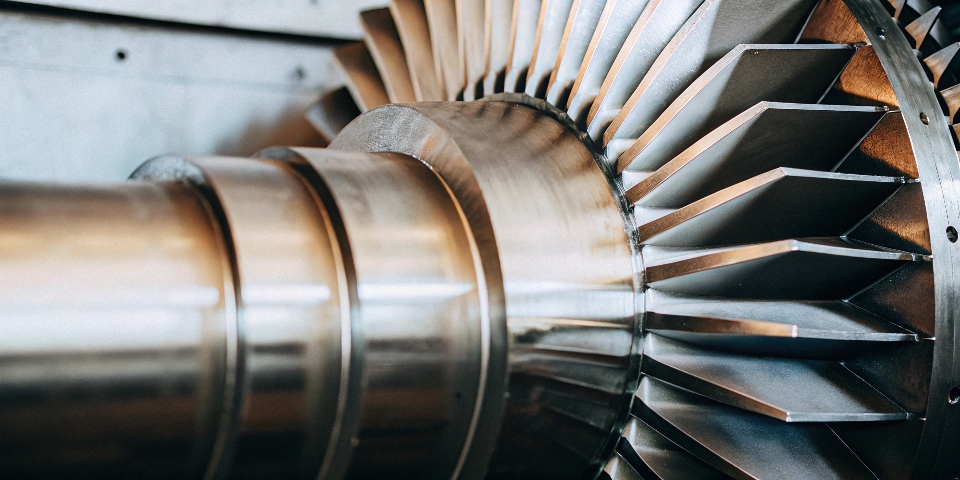

- Jet Engines: This is the heart of the demand. Up to one-third of a jet engine’s weight can be titanium. It is used for compressor blades, discs, and casings because it holds its strength at high operational temperatures where aluminum alloys would fail.

- Airframes: Titanium alloys like Ti-6Al-4V are used for critical structural parts, including the wing supports, fasteners, and landing gear. These parts endure immense stress during takeoff, flight, and landing.

Traceability and Quality

For my clients like Sophie, explaining the importance of certification is key. Aerospace components require materials that meet standards like ISO 9001 and specific aerospace certifications. Our Baoji facility is fully certified to meet these global standards. We provide full documentation for every piece of titanium, tracing it back to the initial ingot. This guarantee of quality is why aerospace remains, and will continue to be, the biggest consumer of titanium.

What is another major use of titanium?

Beyond aerospace, what is another major industry for titanium? You need examples for clients in non-aerospace sectors. I will explain the second most critical application for titanium.

After aerospace, the chemical processing industry is a major user of titanium. Its incredible resistance to corrosion, especially from chlorides and acids, makes it ideal for reactors, piping, and heat exchangers.

I frequently work with purchasing managers from chemical and oil refining companies. Their biggest challenge is equipment longevity in highly corrosive environments. A plant shutdown due to a failed pipe or leaking reactor costs millions. This is where I explain the value of our specialized titanium alloys. While the initial cost might be higher than stainless steel, the total cost of ownership is much lower because titanium equipment lasts years longer with less maintenance.

Resisting the Unresistible

The key advantage of titanium in this sector is its unique ability to resist corrosion from wet chlorine gas and chloride solutions. These substances are notorious for causing pitting and stress corrosion cracking in most other metals.

- Chlor-Alkali Production: This process involves highly corrosive chlorine. Titanium is one of the few materials that can handle it, used for anodes and cell bodies.

- Heat Exchangers: In coastal refineries or desalination plants, equipment is constantly exposed to saltwater. We supply our Grade 7 and Grade 11 alloys, which include palladium, for extra corrosion resistance in these heat exchangers and piping systems.

The table below shows a simple comparison that I often share with clients to illustrate the point.

| Environment | Stainless Steel 316L | Commercially Pure Titanium (Grade 2) |

|---|---|---|

| Seawater | Prone to pitting and crevice corrosion | Excellent resistance |

| Wet Chlorine | Rapidly corrodes | Excellent resistance |

| Nitric Acid | Good resistance | Excellent resistance |

This superior performance in harsh chemical environments makes titanium a major and indispensable material for the industry.

Conclusion

Titanium’s unique properties make it vital in aerospace, chemical processing, and medicine. Its versatility and reliability ensure it remains the top choice for today’s most demanding applications.

-

Learn about the significance of ISO 9001 certification in ensuring quality. ↩