Welding titanium seems straightforward, but failed welds cost time and money. The material cracks, projects stall, and you’re left wondering what went wrong. The secret is the environment.

Titanium must be welded in a vacuum or under a protective inert gas shield. This is because at high temperatures, titanium reacts aggressively with oxygen and nitrogen in the air. This reaction makes the weld brittle, weak, and certain to fail under stress.

I’ve been in the titanium supply chain for over a decade. I’ve seen companies, both large and small, struggle with this exact problem. A customer like Ahmed, who runs a metal distribution business in Turkey, needs to advise his clients correctly. A bad weld not only ruins the part but can also damage a supplier’s reputation. It’s a challenge, but once you understand the “why” behind the process, it becomes much simpler to manage. The key isn’t just about melting metal; it’s about protecting it while it’s most vulnerable. Let’s break down the essential rules for successfully joining this incredible material.

Do you have to weld titanium in a vacuum?

You need to weld titanium, but a vacuum chamber sounds complex and expensive. Is it the only way? Skipping this crucial protection could ruin your entire project and destroy valuable material.

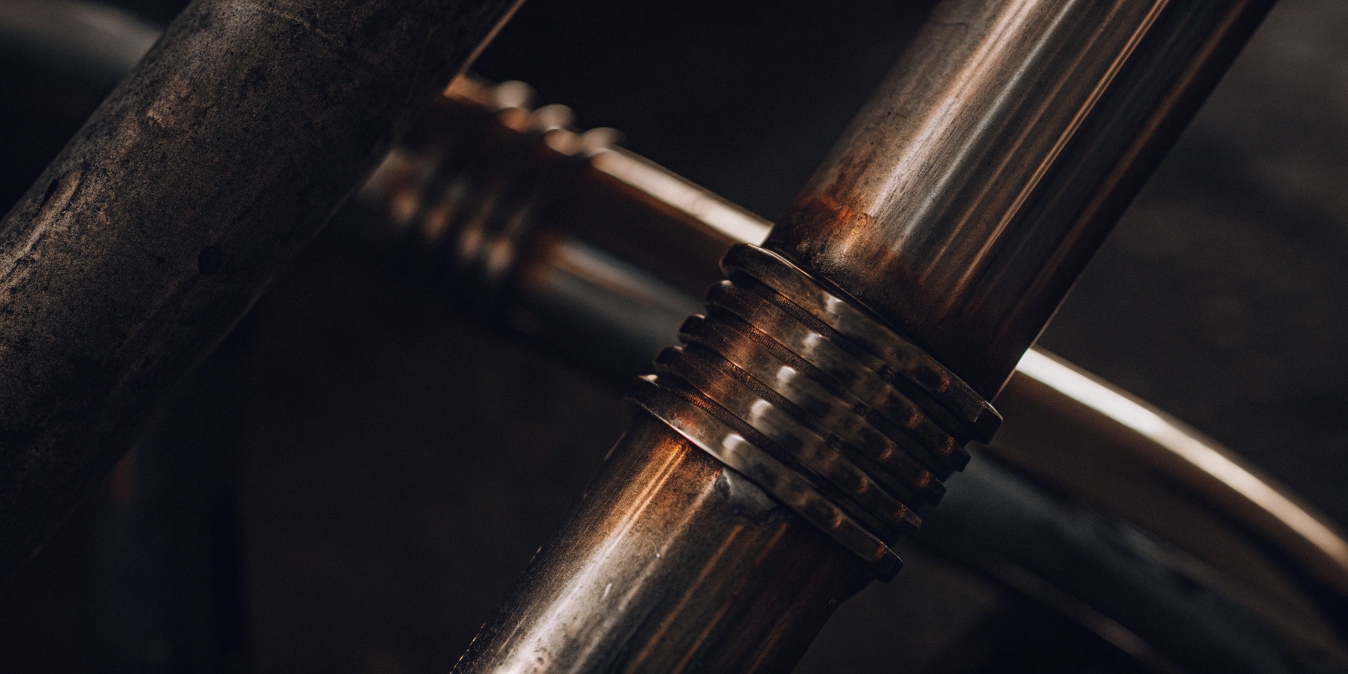

Not always, but you must always shield it from the air. A vacuum provides ultimate protection. However, for many jobs, shielding with a high-purity inert gas like argon is a more common and practical method. This process is known as Gas Tungsten Arc Welding (GTAW or TIG)1.

The non-negotiable rule is that molten titanium must never touch the air. The choice between a vacuum and an inert gas shield depends on the application’s demands. For my clients in the aerospace or military sectors, vacuum welding is often specified for critical components. The purity of the weld is paramount. However, for many industrial and even medical applications, a proper TIG welding setup2 with a good argon shield is perfectly adequate. I’ve advised many small manufacturers, like the ones Ahmed supplies, to invest in high-quality TIG equipment. It’s more accessible than a vacuum chamber and, when done correctly, produces strong, reliable welds. The key is ensuring the gas flow is sufficient to cover not just the molten puddle but also the cooling area behind it.

Here’s a simple comparison to help you decide.

| Method | Protection Level | Common Cost | Best For |

|---|---|---|---|

| Vacuum Welding | Highest Purity | High | Aerospace, nuclear, critical implants |

| Inert Gas Shielding | High Purity | Medium | General industrial, marine, most medical |

| No Shielding | None | – | Guaranteed Failure – Never Use |

Which welding process must be done in a vacuum?

Choosing the right welding process for titanium is confusing. The wrong choice leads to wasted material, unreliable parts, and a reputation for poor quality. Let’s clarify which process absolutely requires a vacuum.

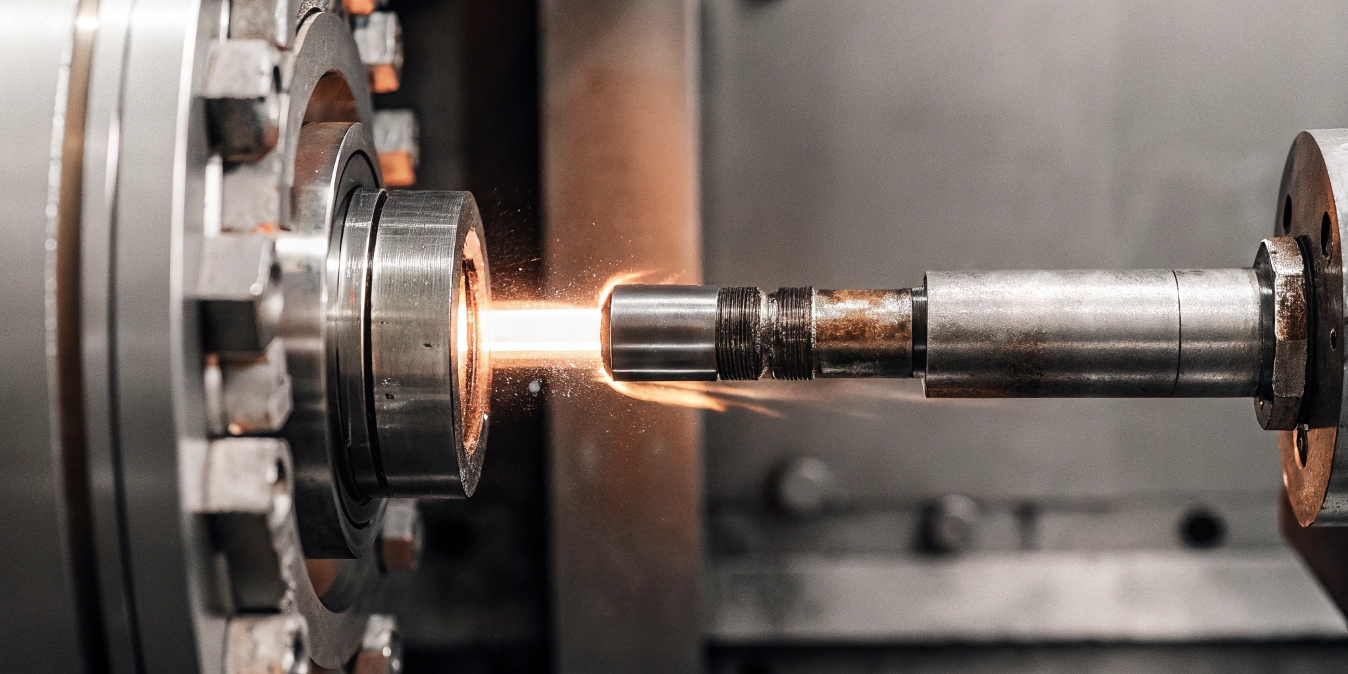

Electron Beam Welding (EBW)3 is a process that must be performed in a vacuum. The vacuum is essential for the electron beam to function. It also provides the perfect shielding environment for titanium, resulting in exceptionally pure and deep welds that are impossible to achieve otherwise.

In my experience supplying titanium ingots for specialized applications, EBW is the go-to process for a reason. Here’s how it works: the machine shoots a highly focused beam of electrons at the metal. These electrons travel at incredible speed, and their energy instantly melts the titanium. If there were air molecules in the way, the electrons would collide with them and scatter, losing all their power. The vacuum chamber clears that path. This has a fantastic side effect for titanium—it creates the ultimate clean room for the weld. I’ve seen this used to join very thick sections of Ti-6Al-4V for military hardware. The weld is deep, narrow, and incredibly strong because it’s free from any atmospheric contamination. While other processes like Laser Beam Welding can also be done in a vacuum for better results, EBW is the one that simply cannot work without it.

What is a vacuum weld?

You hear the term "vacuum weld" mentioned for high-tech projects. Not understanding the term can make you feel left out of important technical discussions. Let’s define it in simple terms.

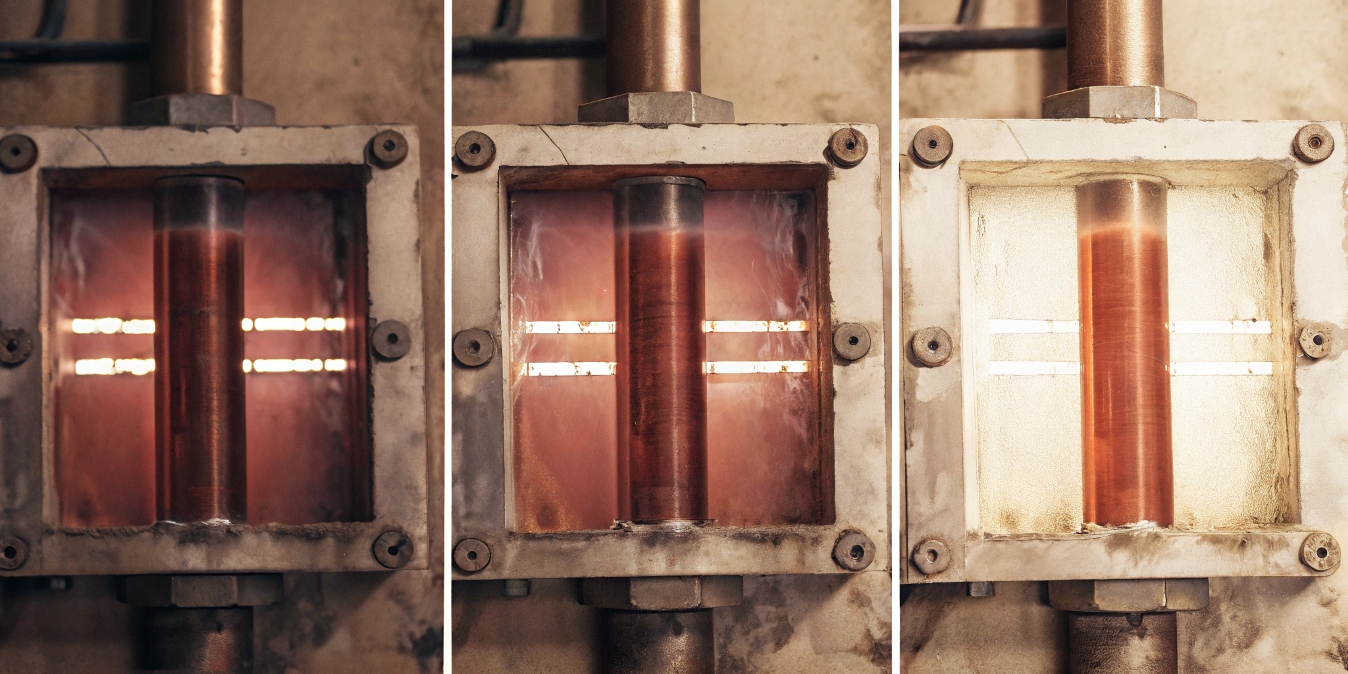

A vacuum weld is a join between metals that is created inside a chamber with almost all the air removed. This low-pressure, or vacuum, environment stops atmospheric gases from reacting with the molten metal. This produces a weld that is exceptionally pure, strong, and reliable.

The process is quite methodical. First, we place the titanium parts to be joined inside a sealed, robust chamber. Then, powerful pumps remove the air until a specific low pressure is reached. Only then is the welding heat source, like an electron beam, activated inside the chamber to melt and fuse the metal. I often see this applied in marine engineering projects that I supply material for. For example, titanium alloy heat exchangers are constantly exposed to corrosive seawater. Any tiny impurity in a weld can become a failure point. By performing the welds in a vacuum, manufacturers ensure the joints are as corrosion-resistant as the base metal itself. This method offers unparalleled control, which is why it is specified for applications where failure is not an option.

The benefits are clear and directly address the challenges of welding titanium.

| Feature of Vacuum | Its Direct Benefit | Why it Matters for Titanium |

|---|---|---|

| No Atmosphere | Prevents Contamination | The weld remains ductile and strong, not brittle. |

| Highly Controlled | Excellent Repeatability | Every weld is as good as the last; perfect for series production. |

| Deep Penetration (EBW) | Welds thick parts in one pass | Creates stronger joints with less heat distortion. |

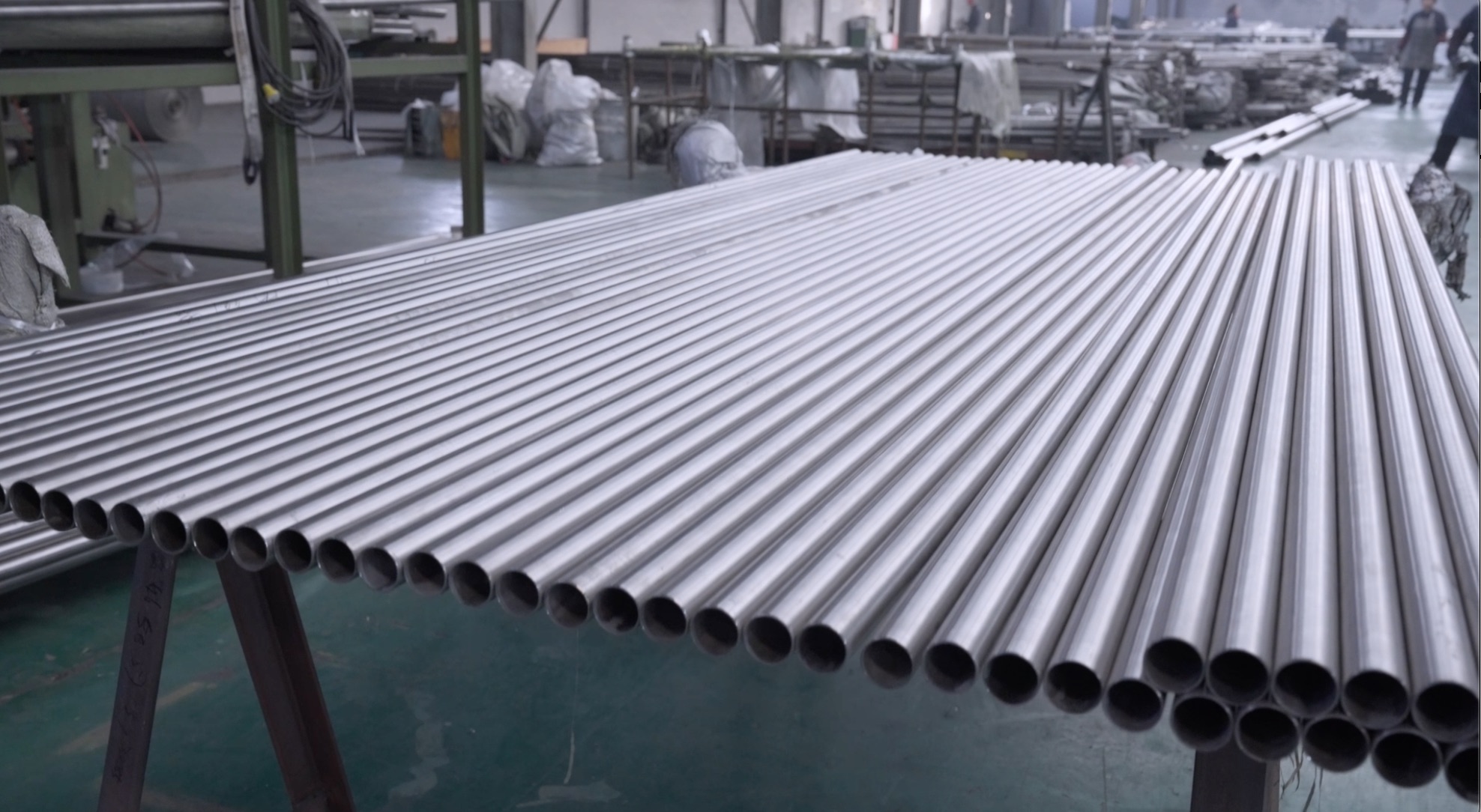

Looking for High-Quality Titanium Tubes and Pipes?

Explore our range of titanium tubing and piping solutions suited for aerospace, medical, and industrial applications. Our products are designed to meet rigorous standards and provide reliable performance in various environments.

Why can’t titanium be welded?

People often say titanium is "impossible" to weld, making fabricators nervous. This widespread myth might stop you from taking advantage of this incredibly useful material. The truth is simpler.

This is a complete myth. Titanium can be welded very well. The challenge is its extreme reactivity with air (oxygen, nitrogen, hydrogen) when heated above 427°C (800°F). Without a perfect shield, like a vacuum or argon gas, the weld absorbs these gases and becomes brittle.

I remember a classic case with a new client making medical-grade titanium rods. They were new to the material and attempted a weld without a proper inert gas shield, thinking a quick tack would be fine. The resulting weld was a rainbow of blue, purple, and straw yellow. While colorful, these are warning signs of severe contamination. The weld was so brittle that the rod snapped with very little force. They had to scrap the entire batch. This taught them a valuable lesson: the problem isn’t the titanium; it’s the procedure. When titanium gets hot, it acts like a sponge for gases in the air. These gases get trapped in the metal’s structure, making it hard and fragile, like glass. Successful titanium welding is all about cleanliness and total isolation from the atmosphere. The material, the filler rod, and the surrounding area must be spotless, and the inert gas or vacuum shield must be flawless.

Conclusion

Welding titanium is not hard, it just demands discipline. It requires an absolutely clean, air-free environment, using either a vacuum or inert gas, to create strong, pure, and reliable joints.