Titanium metal melts at 1,668°C (3,034°F), which is known as the titanium metal melting point. This high melting point makes it crucial for industries needing materials that resist extreme heat. Titanium was named after the Titans of Greek mythology, referencing the mythological giants to symbolize the metal’s strength and enduring qualities. In this article, you’ll learn about titanium’s melting point, its comparison with other metals, and its industrial applications.

Occurrence of Titanium

Titanium is recognized as the 9th most abundant element in the Earth’s crust, accounting for about 0.63% of its mass. This abundant element is found in a wide variety of natural environments, including igneous rocks, sediments, soils, and even bodies of water. Titanium is primarily contained in minerals such as rutile, ilmenite, and anatase, which are distributed across many geological formations worldwide. Major titanium deposits are located in countries like Australia, Canada, China, India, Mozambique, New Zealand, Norway, Sierra Leone, South Africa, and Ukraine, making titanium a globally accessible resource.

Beyond Earth, titanium has also been detected in meteorites and in the Sun, as well as in M-type stars with surface temperatures around 3,200°C. This widespread occurrence highlights titanium’s significance as a chemical element, not only in industrial applications but also in the broader context of planetary and stellar science. Its presence in igneous rocks and other natural sources ensures a steady supply for industries that rely on titanium’s unique properties.

Understanding Titanium’s Melting Point

Titanium’s melting point is more than just a number; it’s a key factor that influences its applications and production processes. With a melting temperature higher than most common metals, titanium is preferred in industries where heat resistance and durability are paramount. In fact, titanium’s melting point is higher than that of most metals, though it is surpassed by a few refractory metals like tungsten.

This high melting point allows titanium to maintain mechanical integrity under extreme conditions, making it ideal for aerospace, automotive, and other high-performance applications.

Exact Melting Temperature

Pure titanium has an approximate melting point of 1,668°C. In its pure form, titanium exhibits this specific melting point, but the presence of impurities or alloying elements can alter this value. This is equivalent to about 3,034°F. This very high melting point makes titanium suitable for applications that require materials to withstand elevated temperatures without losing their structural integrity. Industries can rely on titanium for high-performance applications due to its consistent melting temperature and heat resistance.

At Titonest, we ensure the consistency of melting points by starting with high-purity titanium sponge in our in-house smelting facility, which is a form of pure metal. This approach enhances product reliability for clients in demanding sectors like aerospace and automotive, where maintaining mechanical integrity at high temperatures is essential.

Comparison with Other Metals

When compared to other metals, titanium’s melting point stands out significantly. For instance, aluminum melts at a much lower temperature of 660°C (1,221°F), making titanium about 2,000°F (1,100°C) higher in melting temperature. Similarly, titanium’s melting point is 400°F (220°C) higher than that of steel, which typically melts at around 1,370 to 1,530°C. Titanium also has a higher melting point than iron, which melts at approximately 1,538°C (2,800°F). Iron, one of the earliest established structural metals dating back to 3200 BC, has played a crucial role in the development of alloys and steel production. This superior heat resistance makes titanium ideal for parts exposed to frictional heating, such as turbine blades and brake systems.

While titanium does not exceed the melting temperature of refractory metals like tungsten, its combination of high melting point, corrosion resistance, and durability makes it a strong contender in many industrial applications. These properties give titanium an edge over more common metals in specific high-stress environments.

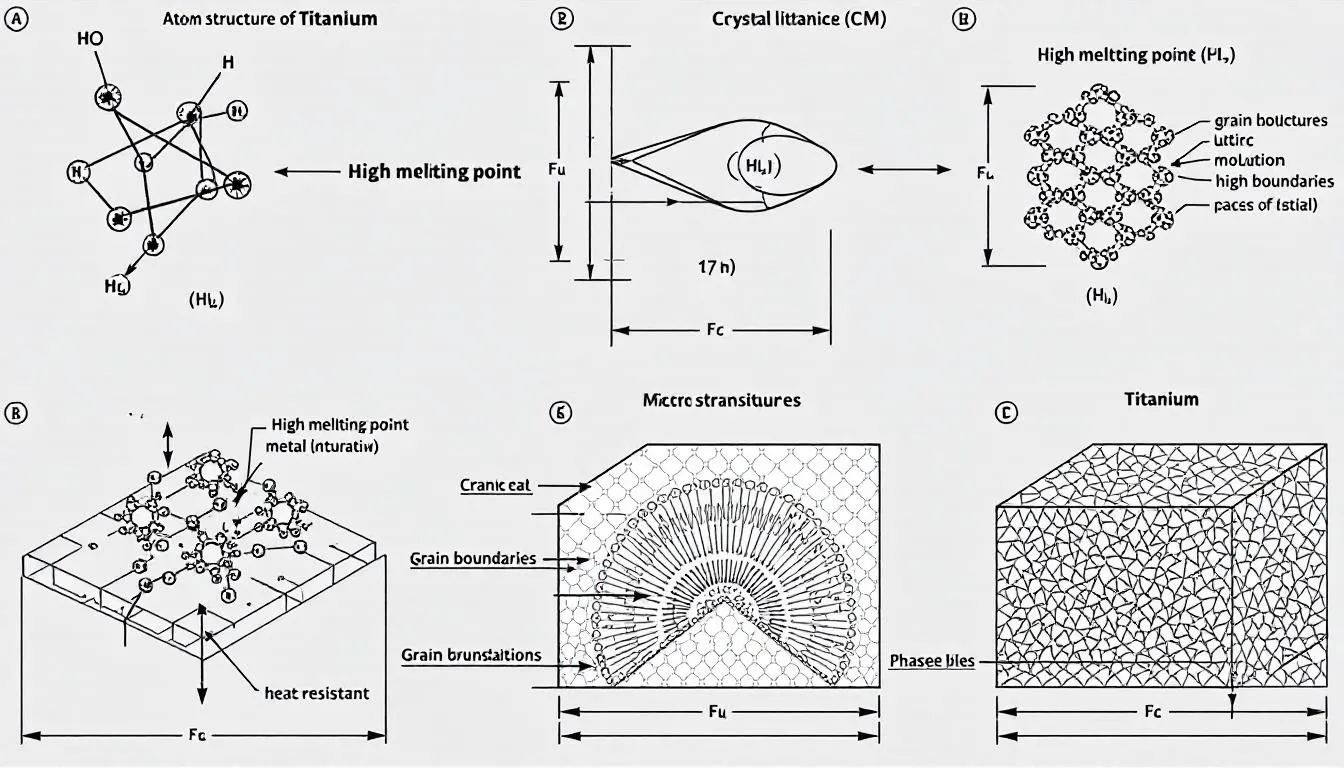

Reasons for High Melting Point

Titanium’s high melting point can be attributed to its strong metallic bonding and dense atomic structure. The higher atomic number of titanium means its atoms vibrate less, requiring more thermal energy to transition from a solid to a liquid state. This atomic-level resilience is why our titanium alloys maintain structural stability in mission-critical applications, from jet engines to nuclear reactors.

Titanium also undergoes a phase change at its transition temperature of 882°C, shifting from the α (hexagonal close-packed) phase to the β (body-centered cubic) phase. This transition temperature significantly affects titanium’s mechanical and thermal properties, such as specific heat, microstructure, and overall performance at high temperatures.

The strong metal metallic element bonds and dense crystal structure make melting titanium a challenging process, requiring significantly more energy compared to metals with lower melting points. This resilience allows titanium to tolerate extreme temperatures, proving indispensable in high-temperature applications.

Functions as a Refractory Metal

Titanium’s high melting point of 1,668°C (3,034°F) classifies it as a refractory metal, making it exceptionally well-suited for high-temperature industrial applications. As a metal with both low density and high strength, titanium stands out among refractory metals for its ability to maintain structural integrity and resist deformation even at elevated temperatures. This combination of properties is especially valuable in the aerospace industry, where titanium is used in the manufacture of heat exchangers, turbine engines, and propeller shafts that must perform reliably under extreme thermal stress.

In addition to aerospace, titanium’s high melting point and excellent resistance to corrosion make it indispensable in a range of industrial applications, from chemical processing equipment to power generation. Its ability to withstand high temperatures without losing strength or succumbing to corrosion ensures that titanium remains a preferred material for components exposed to harsh operating conditions. Whether in the form of pure titanium or advanced titanium alloys, this strong metal continues to set the standard for performance in demanding environments.

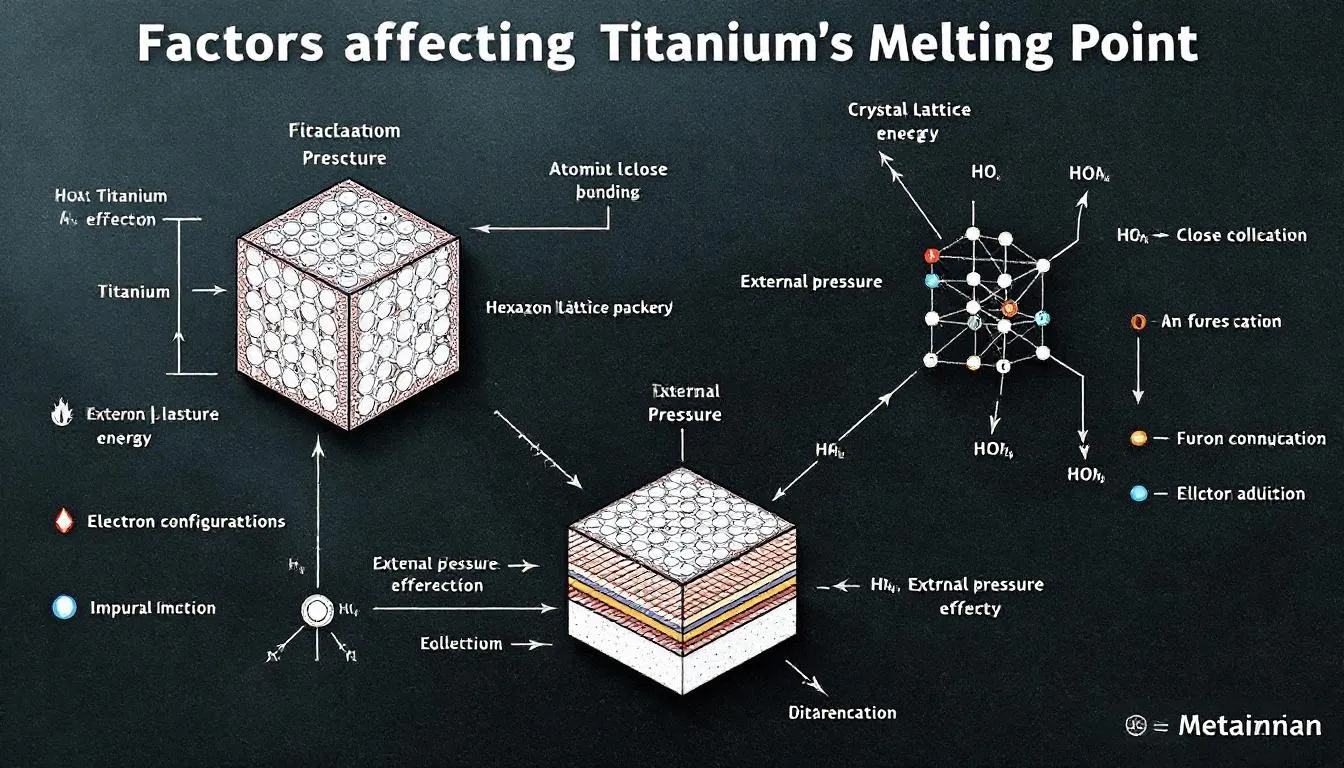

Factors Influencing Titanium’s Melting Point

Several factors influence titanium’s melting point, including its purity, the presence of alloying elements, and external conditions like atmospheric pressure. Understanding these factors is crucial for industries that rely on titanium’s high melting point for their applications.

Alloying titanium with other elements can further influence its melting point and tailor its properties for specific applications.

Purity and Alloying Elements

The purity of titanium plays a significant role in determining its titanium melting point. Higher purity levels typically result in a melting point closer to the standard value of 1,668°C. In medical and aerospace applications, ultra-high-purity grades like 6AL4V Eli are recommended to ensure both biocompatibility and thermal reliability.

Alloying elements can also significantly alter the melting point of titanium. Depending on their characteristics and quantities, these elements can change the melting temperature by up to 450°C. This variability allows for the customization of titanium alloys to meet specific performance requirements in various applications.

Carbon, when present as an alloying element, can refine grain structure and enhance the temperature stability of certain titanium alloys by influencing their microstructure and phase formation.

External Conditions

External conditions such as atmospheric pressure can influence the melting point of titanium. Under high pressure, titanium’s melting point tends to increase due to restricted atomic movement. For customers operating in high-altitude or submarine environments, we tailor our materials to account for pressure-induced melting point shifts.

The presence of reactive gases like oxygen or nitrogen can also affect titanium’s melting point by forming oxides that alter its thermal properties. These factors are critical to consider in environments where titanium is exposed to varying external conditions.

Additionally, phase transformations in titanium alloys, such as the β to ω transition, can lead to an increase in electrical resistivity due to changes in atomic structure.

Applications Leveraging Titanium’s High Melting Point

Titanium’s high melting point opens up a range of applications where heat resistance and titanium’s durability are essential. From aerospace to industrial tubing, titanium’s ability to withstand extreme temperatures makes it a valuable material in various high-performance environments.

Titanium’s durability allows it to maintain performance and resist degradation even in harsh, high-temperature, and corrosive environments.

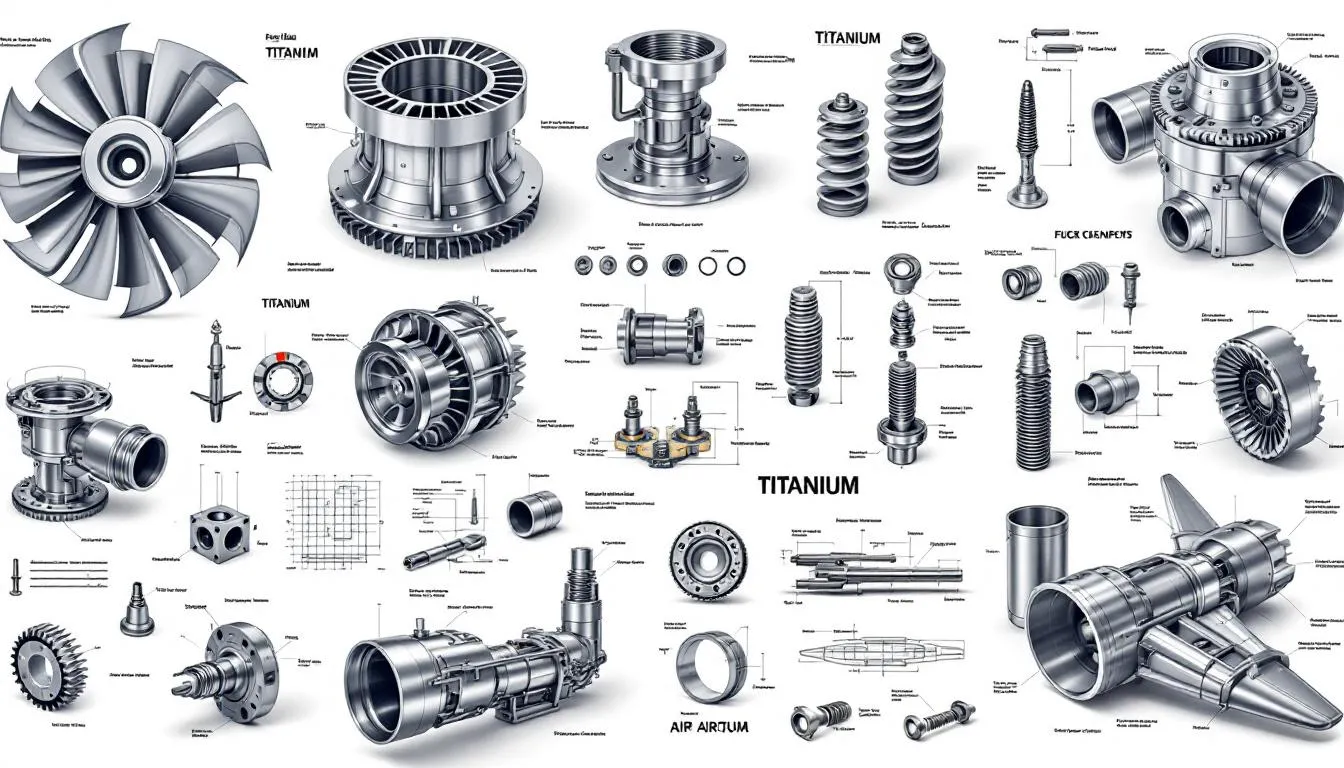

Aerospace Industry

The aerospace industry heavily relies on titanium alloys for their high melting point, toughness, and lightweight properties. Titanium’s light weight helps improve fuel efficiency and increase payload capacity in aerospace vehicles. Titanium alloys used in aircraft and missile construction, such as Ti-6Al-4V, provide excellent resistance to heat, making them ideal for high-performance aerospace applications. Titanium is utilized in critical structural parts, landing gear, firewalls, exhaust ducts, and hydraulic systems within aircraft.

Our titanium meets aerospace-grade certifications, including ISO and national military standards, positioning us as a reliable supplier for critical structural titanium parts. This ensures that the materials used in aerospace applications can withstand the extreme conditions they are exposed to.

Heat Exchangers and Industrial Tubing

Titanium’s heat resistance, high melting point, and corrosion resistant properties make it especially suitable for heat exchangers and industrial tubing. Titanium’s corrosion resistance also makes it ideal for use in marine environments, such as seawater heat exchangers and ship components. In industrial settings, titanium’s corrosion resistance ensures durability in heat exchangers operating at high temperatures. This makes titanium alloys a preferred choice for industrial tubing that can withstand high temperatures and pressures.

In the chemical and petrochemical industries, titanium is utilized for welded pipe and process equipment due to its high melting point and ability to endure extreme temperatures. Our corrosion-tested tubing solutions are popular with petrochemical clients who demand longevity in high-pressure, corrosive environments.

Turbine Engines

Titanium is favored in turbine engines due to its high strength and high-temperature resistance. Titanium alloys are essential for manufacturing turbine blades, which need to withstand high temperatures and maintain their integrity. Titanium alloys used in turbine engines are selected for their high tensile strengths, ensuring reliability under extreme mechanical stress. Our Ti-35V-15Cr β-alloy is engineered specifically for applications requiring both titanium fire resistance and long-term thermal stability, including titanium alloy applications.

The high-temperature stability of titanium is crucial for maintaining the integrity of components in turbine engines, ensuring that they can operate efficiently and safely under extreme conditions.

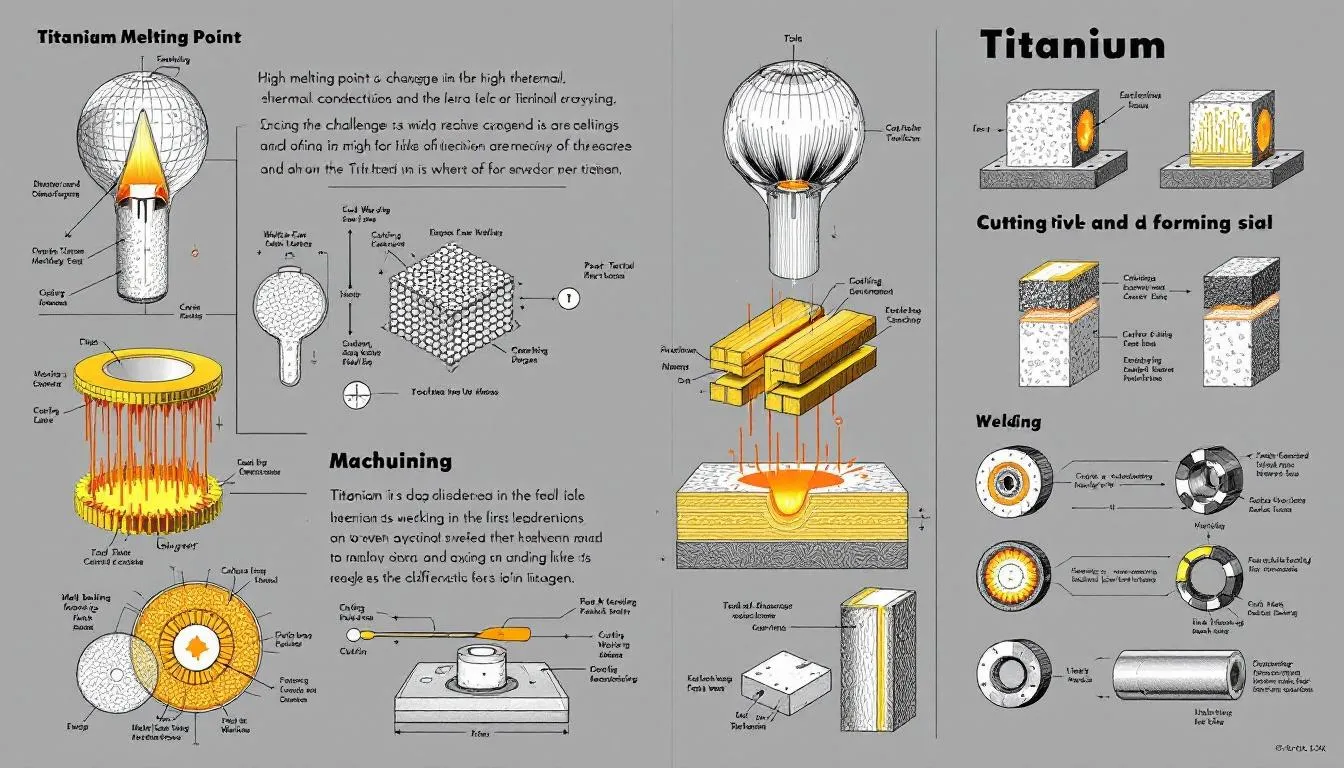

Challenges of Working with Titanium

Working with titanium can be challenging. This is mainly because of its high melting point. Titanium can also catch fire when exposed to certain conditions, such as contact with liquid oxygen or during machining, so strict safety protocols are necessary. Specialized equipment and techniques are required to process titanium effectively, making it a complex material to work with.

Melting and Casting

Melting and casting titanium present unique challenges due to its affinity for hydrogen, which can lead to embrittlement during processing. Hydrogen absorption can cause embrittlement in titanium, making careful temperature and pressure control vital during processing. We mitigate hydrogen embrittlement by using controlled-atmosphere furnaces and crucible cleaning protocols, ensuring metal integrity.

Additionally, when working with titanium, it is necessary to account for its tendency to spring back and the need to remove the alpha case. Machining titanium typically requires different strategies than those used for stainless steel due to its unique material properties.

Machining and Welding

Machining titanium alloys is challenging due to their low thermal conductivity, which causes heat to concentrate during machining and can lead to tool wear. The high chemical reactivity of titanium at elevated temperatures contributes to rapid tool degradation during machining processes. Our team of senior technicians applies experience-based techniques to minimize tool wear and ensure clean welds, especially for ASME-grade piping systems.

Contamination from atmospheric gases is a major cause of joint failure in welded titanium. We address this by using controlled environments and specialized welding techniques, ensuring high-quality joints that meet industry standards.

Titanium Alloys and Their Melting Points

Titanium alloys come in various types, each with its own melting point and properties. These alloys are tailored to specific applications, taking advantage of titanium’s unique characteristics.

α-Alloys

α-Alloys are known for their toughness and stability, making them suitable for various applications. The main alloying chemical element in α-alloys besides Zirconium and Tin is Aluminum. The oxygen content in α-alloys significantly affects their tensile strength and ductility, which is why these alloys are used in the manufacture of aeroengine disks.

Our α-alloys are especially favored in rotational parts where long-term thermal cycling occurs, alloyed to extend component life and ensuring reliability in demanding environments.

α+β Alloys

α+β alloys, such as Ti-6Al-4V, are known for their excellent combination of strength and formability. These alloys are widely utilized in the aerospace industry due to their exceptional mechanical properties. Their high strength and formability make α+β alloys suitable for various applications, including fuselage and support structures.

We supply formable yet strong titanium sheets ideal for high-stress applications by leveraging this dual-phase structure, ensuring both performance, fatigue resistance, and durability.

β-Alloys

β-Alloys primarily consist of beta-phase titanium, characterized by high-temperature stability and strength. An important example of a β-alloy is Ti-35V-15Cr, utilized for its favorable properties in high-temperature applications. These alloys exhibit excellent burn-resistant properties, making them suitable for demanding environments such as aerospace and military applications.

Our β-alloys are part of our premium offerings for clients requiring top-tier burn resistance in extreme environments, ensuring the highest levels of performance and safety.

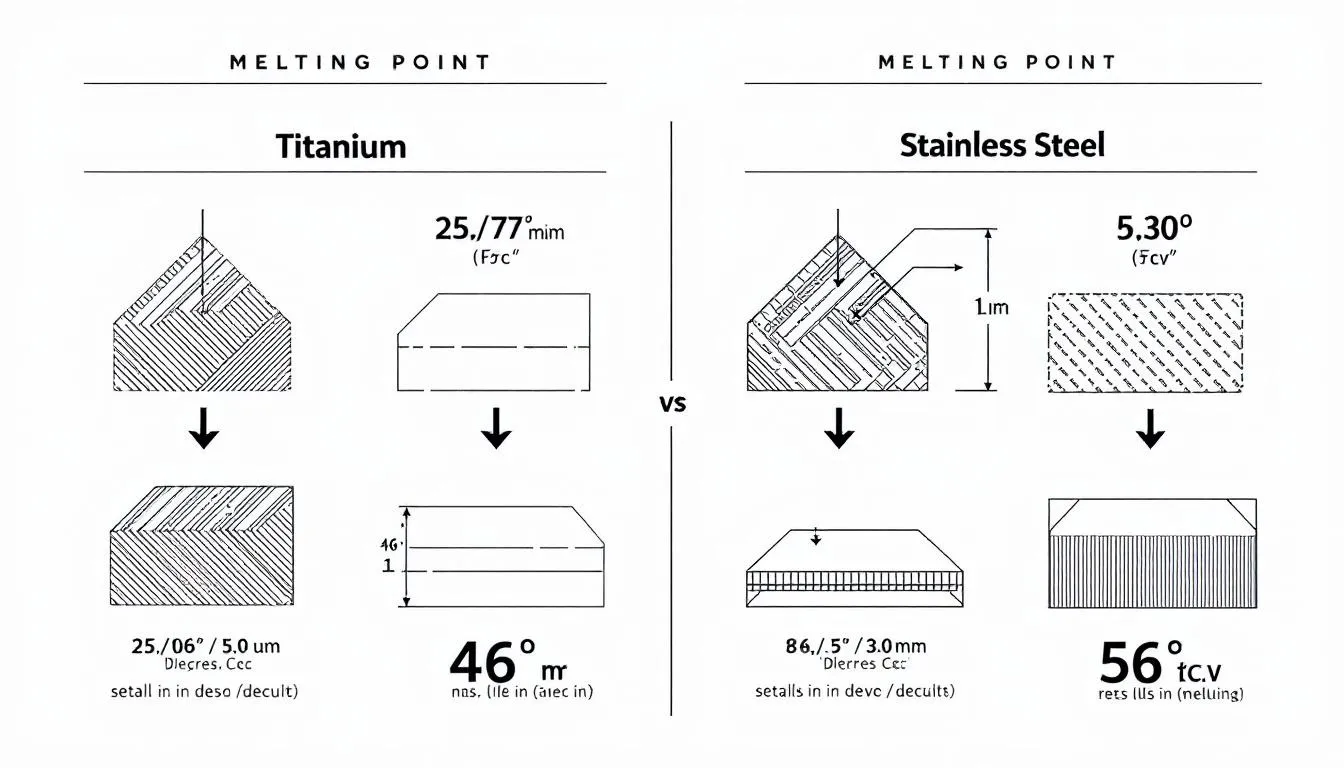

Titanium vs. Stainless Steel: Melting Points and Applications

Comparing the melting points and applications of titanium and stainless steel highlights the unique advantages of each material. Titanium’s higher melting point makes it suitable for extreme environments, while stainless steel offers affordability and ease of fabrication.

Titanium is often added to stainless steel to reduce carbon content, which improves the alloy’s performance and resistance to intergranular corrosion.

Melting Point Comparison

The melting point of titanium is significantly higher than that of many stainless steel grades. Titanium melts at approximately 1,668°C (3,034°F), whereas stainless steel typically melts at around 1,370°C to 1,510°C (2,500°F to 2,750°F). This higher melting temperature allows titanium to be used in high-temperature applications where stainless steel might fail.

Stainless steel is often favored in construction, kitchenware, and other applications due to its affordability and ease of fabrication. However, in high-risk areas requiring improved safety margins and lifespan, our clients often replace stainless steel with titanium to take advantage of its superior heat resistance and durability.

At Titonest, our vertical integration—from sponge to final machining—enhances traceability and cost control throughout the production chain, ensuring high-quality titanium products for our clients.

Environmental Impact of Titanium Production

The production of titanium metal, while essential for many advanced technologies, comes with notable environmental challenges. The most widely used method, the Kroll process, involves converting titanium tetrachloride into titanium metal using magnesium or sodium. This process is energy-intensive and generates a significant amount of waste byproducts, contributing to the overall environmental footprint of titanium production.

Mining titanium ores can also impact local ecosystems, leading to soil and water pollution and the disruption of habitats. As awareness of these issues grows, the titanium industry is increasingly focused on developing more sustainable practices. Innovations such as recycling titanium scrap and exploring alternative extraction technologies aim to reduce the environmental impact associated with titanium metal production. By adopting greener methods, the industry seeks to balance the benefits of titanium with a commitment to environmental responsibility.

Future Outlook for Titanium

Looking ahead, the future of titanium is bright, with demand expected to rise across aerospace, industrial, and medical applications. The ongoing development of new titanium alloys and advanced manufacturing techniques is set to enhance the performance and cost-effectiveness of titanium, making it more competitive with other metals. As industries seek materials that are both corrosion resistant and lightweight, titanium’s unique combination of properties positions it as a material of choice for next-generation technologies.

Emerging applications, such as 3D printing and advanced composites, are further expanding the role of titanium in modern manufacturing. In medical applications, titanium’s biocompatibility and resistance to corrosion continue to drive innovation in implants and devices. As the global population grows and urbanizes, the need for strong, durable, and corrosion-resistant alloys will only increase. With ongoing investment in research and sustainable production, titanium is poised to remain at the forefront of materials science and industrial progress for years to come.

Summary

Titanium’s high melting point is a defining characteristic that sets it apart from other metals, making it invaluable in high-performance applications across various industries. From aerospace to industrial tubing and turbine engines, the ability of titanium to withstand extreme temperatures while maintaining structural integrity is crucial.

Titanium is also non toxic, which contributes to its widespread use in medical and consumer products.

Despite the challenges of working with titanium, including its high melting point and the complexity of the Kroll process, the benefits far outweigh the difficulties. Titanium’s exceptional properties make it a material of choice for applications where durability, heat resistance, and long-term performance are essential. As industries continue to evolve, titanium will undoubtedly play a pivotal role in pushing the boundaries of what is possible.

Frequently Asked Questions

What is the exact melting point of titanium?

The exact melting point of pure titanium is approximately 1,668°C (3,034°F).

How does titanium’s melting point compare to that of stainless steel?

Titanium’s melting point is significantly higher at 1,668°C, whereas stainless steel ranges from 1,370°C to 1,510°C. This makes titanium more suitable for high-temperature applications.

What factors influence the melting point of titanium?

The melting point of titanium is influenced by factors such as purity, the presence of alloying elements, and external conditions like atmospheric pressure and reactive gases. Understanding these factors is crucial for applications involving titanium.

Why is titanium preferred in the aerospace industry?

Titanium is preferred in the aerospace industry because of its lightweight nature, high melting point, toughness, and ability to endure extreme temperatures. This combination of properties makes it ideal for enhancing aircraft performance and durability.

Titanium’s high strength and light weight also make it a popular choice for premium golf clubs and other sporting equipment.