Struggling to explain what titanium really is? It sounds complex, but it’s simpler than you think. You just need a clear, basic definition to build on.

Titanium is a pure chemical element with the symbol Ti. It is refined from natural ores found in the earth’s crust. Here at our plant, we have been smelting our own titanium ingots since 2008 to ensure the highest purity and complete control over the final product.

Understanding that titanium starts as a pure element is the first step. But this simple fact opens up more questions. For example, if it’s a pure element, what are "titanium grades"? And what makes this single element so useful in advanced industries like aerospace and medicine? The answers lie in how we process and use it. Let’s look closer at the details that matter for product managers like Lisa, who need to communicate these points clearly to their teams and customers. This knowledge will help you select the right material with confidence.

What Elements Make Up Titanium?

Are you confused when you see different titanium grades? You need to explain to your team if "titanium" means a pure metal or a mix of different things.

Pure titanium is an element. But we often mix it with other elements like aluminum and vanadium to create titanium alloys. These alloys are called "grades," and each one has unique properties designed for specific jobs, like Grade 5 for strength or Grade 2 for corrosion resistance.

When we talk about titanium, it’s important to know the difference between pure titanium and titanium alloys. This is a very common point of confusion, but it’s simple when you break it down. Think of it like cooking. You start with a main ingredient—in this case, pure titanium—and then you add other things to get a specific result.

Commercially Pure (CP) Titanium1 vs. Titanium Alloys

Commercially Pure (CP) titanium is over 99% pure titanium. We separate it into different grades based on the amount of oxygen and iron it contains. For example, Grade 1 is the purest and most formable, while Grade 4 is the strongest of the CP grades. I often recommend Grade 2 to product managers like Lisa for chemical equipment because it has a great balance of strength, formability, and excellent corrosion resistance.

Titanium alloys, on the other hand, are mixtures. We add other elements to enhance certain properties. The most famous one is Grade 5 (Ti-6Al-4V), which contains 6% aluminum and 4% vanadium. These additions make it much stronger than pure titanium, which is why it’s a top choice for aerospace parts.

| Feature | Commercially Pure (CP) Titanium | Titanium Alloys |

|---|---|---|

| Composition | >99% Titanium | Titanium + other elements (e.g., Al, V) |

| Main Advantage | Excellent corrosion resistance, formability | High strength, specific performance |

| Common Grades | Grade 1, Grade 2 | Grade 5 (Ti-6Al-4V), Grade 23 (Ti-6Al-4V ELI) |

| Typical Use | Chemical processing, architecture | Aerospace, medical implants, performance parts |

As an engineer, I see firsthand how these small changes in composition create materials for totally different worlds. Choosing the right one starts with knowing if you need the purity of CP grades or the specific strength of an alloy.

What Is So Special About Titanium?

Trying to justify the higher cost of titanium over materials like stainless steel? You need to show that its unique benefits are worth the investment for high-performance applications.

Titanium is special because of its high strength-to-weight ratio, incredible corrosion resistance, and excellent biocompatibility2. It is as strong as some steels but about 45% lighter, making it perfect for aerospace and medical devices where performance is critical.

When a product manager like Lisa asks me why they should choose titanium, I usually focus on three game-changing features. These aren’t just small improvements; they are properties that allow for new designs and higher levels of performance that other materials simply cannot match. From my experience in the plant, watching these materials get forged and tested, these three points are what our most demanding clients care about.

The Power of Being Light and Strong

The strength-to-weight ratio is titanium’s most famous quality. I remember working with a client who was redesigning a hydraulic pump for an aircraft. They switched from stainless steel to our Grade 5 titanium. The part was just as strong, but it was almost half the weight. This weight saving on an airplane means less fuel consumption and a bigger payload. For Lisa, explaining this benefit is key. It’s not just about the material cost; it’s about the lifetime value and efficiency it brings to the final product.

Resisting the Toughest Environments

Titanium’s corrosion resistance is another major advantage. This is because titanium naturally forms a very thin, stable, and tough layer of titanium dioxide on its surface when it is exposed to air or water. This oxide layer is like a perfect shield. It protects the metal underneath from attack by acids, saltwater, and industrial chemicals. This is why we export so much titanium for chemical processing equipment. Unlike some types of stainless steel that can pit or corrode in harsh chloride environments, titanium remains unaffected. This reliability is something Lisa can promise her customers.

Working in Harmony with the Body

Finally, its biocompatibility is what makes it a star in the medical field. The human body does not see titanium as a foreign substance, so it doesn’t cause allergic reactions or get rejected. This enables it to fuse directly with bone in a process called osseointegration. We will discuss this more in the next section.

What Does Titanium Do To Your Body?

Are you concerned about using titanium in medical devices? You need to assure your clients and internal teams that the material is completely safe for contact with the human body.

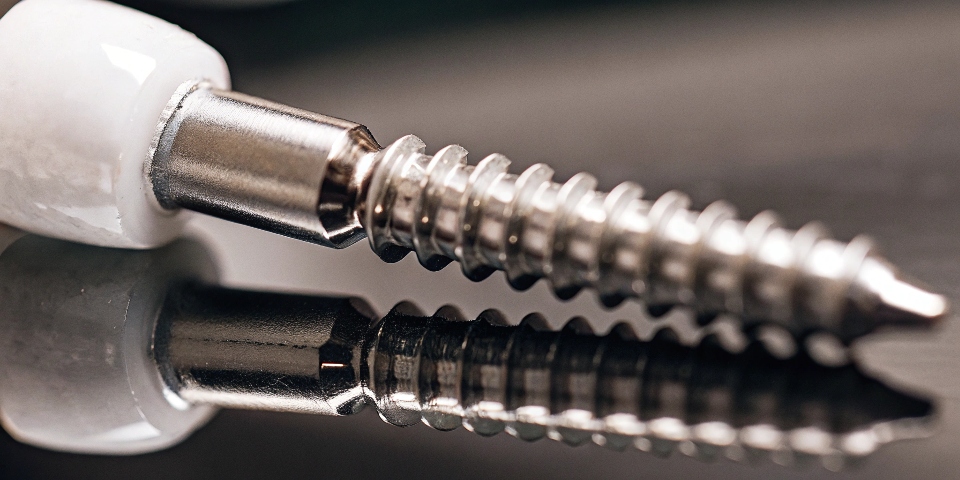

Medical-grade titanium is extremely safe and biocompatible, meaning it does not harm or react with the human body. It is inert, and the body does not reject it. This is why it is widely used for implants like hip joints, bone screws, and dental fixtures.

One of the most important jobs I have is ensuring the quality of our medical-grade titanium. Product managers like Lisa need absolute confidence in the material’s safety, and the science behind titanium’s biocompatibility is very clear. It doesn’t do anything harmful to the body; in fact, its ability to do nothing at all is precisely what makes it so valuable.

Why Is Titanium Biocompatible?

The reason titanium is so friendly to the human body goes back to that protective oxide layer I mentioned earlier. This titanium dioxide3 (TiO₂) film is incredibly stable and passive. It acts as a barrier that prevents any metal ions from the titanium from leaking into the body’s tissues or fluids. Other metals, like nickel or cobalt, can release ions that may cause allergic reactions or other negative effects in some patients. Titanium simply doesn’t do this. My clients who use our Grade 23 titanium for orthopedic implants consistently report excellent performance with almost no cases of rejection.

Common Medical Applications and Grades

The medical field relies heavily on specific titanium grades. Here’s a look at the most common ones:

- Grade 5 (Ti-6Al-4V): This is the workhorse alloy used for things like bone screws, plates, and hip replacement stems. Its high strength is crucial for load-bearing applications.

- Grade 23 (Ti-6Al-4V ELI): The "ELI" stands for "Extra Low Interstitials." This is a higher-purity version of Grade 5 with less oxygen and iron. This makes it more fracture-resistant and even more biocompatible, making it the top choice for permanent implants like pacemakers cases and artificial heart valves.

Our factory is certified to produce these medical-grade materials, and we follow strict ASTM standards. This certification provides the proof Lisa needs to assure her customers that the titanium they are using is safe, reliable, and of the highest quality.

Is Titanium Radioactive or Not?

Facing strange questions about material safety from non-technical people? You need a simple, direct answer to dismiss fears about radioactivity and build trust in the material’s safety.

No, titanium is not radioactive. It is a stable, naturally occurring element that does not emit any harmful radiation. Our smelting and manufacturing processes follow strict international standards to guarantee that the final material is completely safe and non-hazardous.

Sometimes, unfounded fears can become a roadblock for a project. The question of radioactivity is one of them. For a product manager like Lisa, having a clear, confident, and scientifically sound answer is essential. I want to be very clear on this point, drawing from my hands-on experience as an engineer.

Understanding Stability

Radioactivity happens when an element has an unstable nucleus, causing it to break down and release energy in the form of radiation. The elements we think of as radioactive, like uranium or plutonium, have this unstable nature. Titanium, however, is on a completely different part of the periodic table. Its natural isotopes are all stable. This is a fundamental characteristic of the element itself. There is no natural process that would make a piece of titanium radioactive.

Safety and Certification in Our Plant

In all my years working at our plant, from handling the raw titanium sponge to inspecting the final forged bars, radioactivity is a total non-issue. It’s simply not a property of the material. Our quality control processes are intense. We adhere to ISO 9001 and military-grade standards, which involve rigorous testing for purity and structural integrity. These certifications are a guarantee to our clients that the material is exactly what we say it is: pure, strong, and completely safe. When Lisa presents our material certificates to her clients, she is providing documented proof that our titanium is free from any hazardous properties, including radioactivity. This assurance is critical for applications in medicine and aerospace, where safety is the number one priority.

Conclusion

Titanium is a pure element known for its strength, light weight, and corrosion resistance. It is safe, biocompatible, and non-radioactive, making it a trusted material for high-tech industries.