Are you confused by the term "titanium steel"? It sounds advanced, but this confusion can lead to costly material selection errors. Let’s clarify what this popular marketing term really means.

"Titanium steel" is a marketing name for 316L stainless steel. It is not an officially recognized alloy and contains little to no actual titanium. It’s an iron-based alloy1 valued for its appearance and affordability, not for titanium’s unique properties.

Now that you know "titanium steel" is a misleading name, it probably brings up more questions. You might wonder how it truly compares to actual titanium, especially when you’re making decisions for critical projects. Let’s break down the key differences to give you the clarity you need.

Is titanium steel the same as titanium?

Have you been told that titanium steel is a cheaper, yet comparable, alternative to titanium? Believing this common misconception could seriously compromise your product’s performance and safety. Let’s look at the facts.

No, they are completely different materials. Titanium steel is 316L stainless steel, an alloy based on iron. Pure titanium is a distinct chemical element (Ti). They have separate chemical compositions, densities, and performance characteristics that make them suitable for very different applications.

As an R&D engineer in Baoji, I explain this difference to product managers like Lisa nearly every week. "Titanium steel" is a commercial name for a type of stainless steel, while titanium is a fundamental element with its own family of high-performance alloys2. Confusing the two can lead to major engineering failures. Let’s go deeper.

Chemical Makeup

The core difference is their base element. Titanium steel’s main component is iron, mixed with chromium and nickel to resist rust. Titanium alloys, on the other hand, are based on the element titanium, often mixed with aluminum and vanadium to enhance strength.

Key Property Comparison

Their physical properties are worlds apart. A client needing a lightweight, biocompatible part for a medical device simply cannot substitute it with heavy stainless steel. I often use this simple table to make the distinction clear for procurement teams.

| Feature | Titanium Steel (316L Stainless Steel) | Certified Titanium (e.g., Grade 2) |

|---|---|---|

| Main Element | Iron (Fe) | Titanium (Ti) |

| Density | ~8.0 g/cm³ (Heavy) | ~4.5 g/cm³ (Lightweight) |

| Biocompatibility | Low (Contains Nickel) | High (Inert in the body) |

| Common Standard | AISI 316L | ASTM B265, ASME SB265 |

For any high-stakes industry, we always specify certified titanium grades, never a vague marketing term.

Is titanium steel good quality?

Thinking "titanium steel" sounds strong and premium? It must be good quality, right? The quality of this material is entirely dependent on its intended use. Using it in the wrong context is a recipe for failure.

Yes, for certain applications, titanium steel (316L) is a very good quality material. It is durable, corrosion-resistant, and visually appealing for consumer goods like jewelry and watches. However, its quality is insufficient for demanding industrial, medical, or aerospace applications where certified titanium is required.

"Quality" is a relative term. My experience exporting to over 10 countries has shown me a clear divide in how materials are selected based on this idea of quality.

Where Titanium Steel Quality Shines

For industries where budget and aesthetics are the main drivers, "titanium steel" is an excellent choice. It performs very well in:

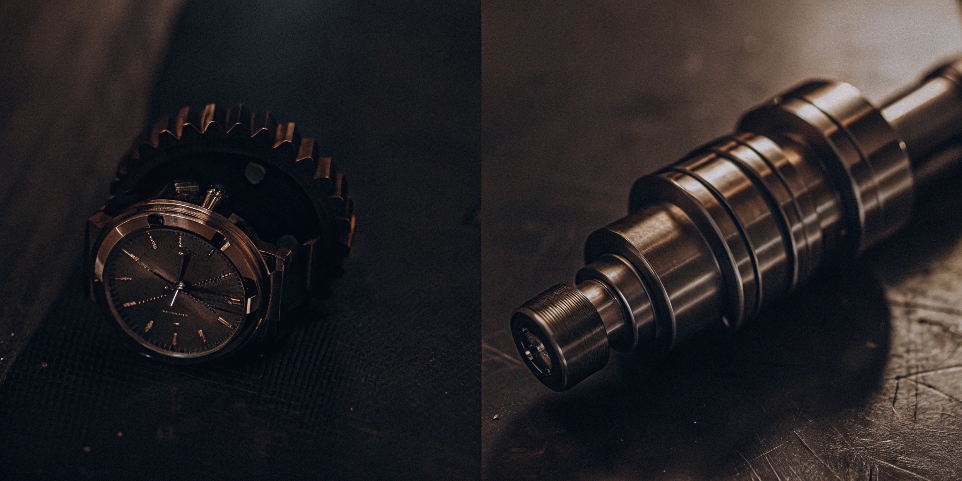

- Fashion jewelry and accessories

- Watch cases and bands

- Decorative hardware and fixtures

In these roles, its scratch resistance, polished finish, and affordability are the definition of "good quality." It gets the job done reliably and looks great.

Where Its Quality Falls Short

However, in high-performance sectors, "quality" means something else entirely. It means predictable, certified performance under extreme stress. My team in Baoji works with global standards like ASTM and ASME every day. These certifications are non-negotiable for industries like chemical processing or medical manufacturing. When a product manager like Lisa needs a material for a tank that will hold corrosive chemicals, we don’t discuss "titanium steel." We start and end the conversation with certified titanium grades like Grade 2 or Grade 7, because true quality here means guaranteed safety and longevity.

Does titanium steel tarnish or rust?

Are you worried that your new "titanium steel" item will quickly lose its shine? Nobody wants to see their purchase ruined by ugly rust spots or tarnish. Let’s discuss what you can realistically expect.

Titanium steel (316L stainless steel) is highly resistant to both tarnish and rust in normal conditions. Its chromium content creates a protective surface layer. However, in harsh saltwater environments, it can still be susceptible to pitting corrosion3 over time, unlike superior titanium alloys.

This is one of the most common questions I get, particularly from clients working in marine engineering. The answer lies in the material’s chemistry.

The Science of "Stainless"

The name "stainless steel" is well-earned. 316L grade contains a significant amount of chromium, which reacts with oxygen to form a very thin, invisible, and durable protective layer on the steel’s surface. This passive layer shields the iron from moisture and air, preventing the chemical reaction that causes rust and tarnish. For everyday items, this protection is more than enough.

The Saltwater Exception

However, this protective shield has a known weakness: chloride. The salt found in seawater is rich in chlorides, which can aggressively attack and break down the passive layer on stainless steel. This can create tiny, localized holes known as pitting corrosion. Based on my team’s decade of smelting expertise, this makes 316L a risk for critical, long-term marine components. That’s why, for a seawater heat exchanger or underwater sensor housing, we always advise clients to use certified titanium. Alloys like Grade 7 titanium (with added palladium) or Grade 23 titanium offer near-total immunity to saltwater corrosion, ensuring long-term stability and safety.

What are the disadvantages of titanium steel?

Titanium steel appears to be a great, affordable material, but are there any hidden downsides? Overlooking its limitations can lead to product failure, safety risks, and unexpected expenses down the road.

The primary disadvantages of titanium steel (316L) are its high weight, low strength-to-weight ratio, and poor biocompatibility4 due to nickel content5. It is also less corrosion-resistant6 than specialized titanium alloys in highly aggressive chemical environments.

As an applications engineer, my job is to match the right material to the right task. While "titanium steel" is a useful material, it’s critical to understand its specific drawbacks before selecting it.

High Weight and Lower Strength-to-Weight Ratio

First and foremost, it is heavy. 316L stainless steel is nearly twice as dense as titanium. For any application where weight is a factor—from aerospace components to high-performance bicycles—this is a significant disadvantage. Its strength is good, but when you factor in its weight, its performance pales in comparison to advanced titanium alloys7.

Lack of Biocompatibility

This is a critical point that cannot be overlooked. From our R&D work in Baoji Titanium Valley, we know that medical applications have zero tolerance for certain elements. "Titanium steel" contains nickel, a common allergen that can cause serious reactions and prevent human tissue from integrating with an implant. This makes it completely unsuitable for any device placed inside the body. For medical products like orthopedic screws, pacemakers, and dental implants, the industry relies exclusively on certified medical-grade titanium like Ti 6AL-4V ELI. It is chosen because it is inert, non-toxic, and accepted by the human body.

Conclusion

In summary, "titanium steel" is a trade name for stainless steel. It is excellent for general use, but for high-performance, lightweight, or medical applications, always trust certified real titanium alloys.

-

Learn about iron-based alloys and their uses in various industries. ↩

-

Discover the benefits of high-performance alloys in demanding industries. ↩

-

Understanding pitting corrosion can help you choose materials for harsh environments. ↩

-

Discover why biocompatibility is crucial for medical applications and material selection. ↩

-

Learn about the implications of nickel in materials used for medical devices. ↩

-

Explore the factors that contribute to corrosion resistance in materials. ↩

-

Discover the advantages of advanced titanium alloys for high-performance applications. ↩