Choosing the wrong metal means costly corrosion failures and downtime. This can risk safety and hurt your bottom line. Understanding their key differences ensures you select the best material.

Titanium is far superior to stainless steel in corrosion resistance. Its stable, self-healing titanium dioxide (TiO₂) passive layer provides excellent protection, especially in chloride environments like seawater where stainless steel is vulnerable to pitting and crevice corrosion.

The simple answer is titanium. But in the real world, the specific corrosive environment, your budget, and the required lifespan of the equipment matter. The choice is not always so simple. Let’s look closer at specific questions you might face. This will help you make a confident choice for your projects and explain it clearly to both engineers and your sales team.

Which is more resistant to corrosion, titanium or stainless steel?

You are evaluating titanium and stainless steel for a critical component. Choosing incorrectly means facing early replacement, maintenance headaches, and unexpected operational shutdowns. Here is a direct comparison to help you decide.

Titanium is significantly more corrosion-resistant than stainless steel. The titanium dioxide layer on its surface is tougher and more stable than the chromium oxide layer on stainless steel, especially when exposed to salts, acids, and industrial chemicals.

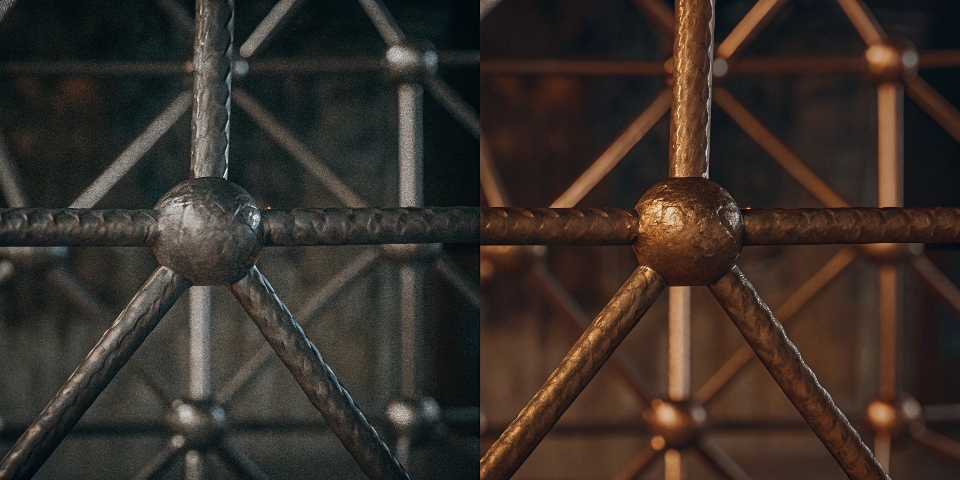

The Power of the Passive Layer

The key to corrosion resistance is a material’s "passive layer." This is a thin, invisible film of metal oxide that forms on the surface when exposed to air. It protects the metal underneath from attack.

Titanium’s passive layer is made of titanium dioxide (TiO₂). This layer is extremely tough. If it gets scratched, it instantly reforms as long as any trace of oxygen or water is present. This makes it incredibly reliable. In our lab, we ran an ASTM B117 salt spray test1. After 1,000 hours, the Grade 2 titanium samples looked brand new. The 316L stainless steel samples, however, were covered in small pits.

Stainless steel relies on a chromium oxide (Cr₂O₃) layer. This layer is also effective, but it has a weakness. Chloride ions, which are found in seawater, road salt, and many industrial chemicals, can break it down. This breakdown causes localized corrosion like pitting and crevice corrosion, which can lead to sudden failure.

| Feature | Titanium (Grade 2) | Stainless Steel (316L) |

|---|---|---|

| Passive Layer | Titanium Dioxide (TiO₂) | Chromium Oxide (Cr₂O₃) |

| Self-Healing | Extremely fast and robust | Slower, requires more oxygen |

| Chloride Resistance | Excellent | Vulnerable to pitting |

| Typical Failure | General corrosion in very aggressive chemicals | Pitting, Crevice Corrosion |

For a product manager like Lisa, this is a crucial distinction. Titanium offers a "fit and forget" solution in many cases, while stainless steel may require more monitoring and a shorter design life.

What is the best metal to resist corrosion?

You need the absolute best material for a highly corrosive job. Picking a metal that is just "good enough" is not an option. It can lead to catastrophic failures and severe financial losses. While titanium is excellent, some metals are even better in specific situations.

Titanium is the best all-around choice for most corrosive environments. But for extreme conditions, other metals can perform even better. Zirconium excels in strong alkalis, and Tantalum is unmatched in hot, concentrated acids. For certain acids, Grade 7 titanium is the superior option.

Beyond Titanium: Zirconium and Tantalum

The "best" metal always depends on the exact chemical environment, temperature, and pressure. While titanium is a fantastic workhorse, we sometimes need to look at more specialized materials.

Zirconium is my recommendation for equipment handling certain strong acids and most alkaline solutions. It shows incredible resistance to sulfuric and hydrochloric acid, where some grades of titanium might struggle.

Tantalum is the ultimate choice for corrosion resistance. Think of it as being almost as inert as glass. It can handle hot, concentrated acids without any issue. However, its very high cost means we only use it when no other metal will survive.

We also have special titanium alloys. Grade 7 titanium contains a small amount of palladium. This small addition makes a huge difference. It increases resistance to crevice corrosion in reducing acids and hot, high-chloride brines by a factor of ten. If Lisa is specifying a reactor for hot chlorinated acids, Grade 7 provides a critical safety margin over standard titanium.

| Metal | Best Use Case | Main Limitation |

|---|---|---|

| Titanium (Grade 2) | Seawater, Chlorides, Oxidizing media | Reducing acids without oxidizers |

| Titanium (Grade 7) | Reducing acids, High-Chloride Brines | Higher initial cost |

| Zirconium | Most Acids, Strong Alkalis | Cannot handle ferric or cupric chlorides |

| Tantalum2 | Hot, Concentrated Acids | Extremely high cost |

Understanding this hierarchy helps you match the right material to the level of risk and performance needed for the application.

Why use titanium instead of stainless steel?

Stainless steel is cheap, and your engineers are familiar with it. But using it in the wrong place, especially where chlorides are present, leads to production halts and safety incidents. Titanium delivers superior lifetime value, even though it costs more upfront.

Use titanium for its immunity to chloride stress corrosion cracking, a common failure for stainless steel. It also has a much lower corrosion rate and is 45% lighter, providing long-term reliability and major structural benefits.

Lifetime Value and Reliability

When you look beyond the initial purchase price, titanium’s advantages become very clear. The decision is not just about corrosion; it’s about total cost of ownership and safety.

A huge problem for common stainless steels like 304L and 316L is Chloride Stress Corrosion Cracking (SCC). This happens when the material is under stress in a chloride environment, even a mild one. It can cause sudden, brittle failure without warning. Titanium is completely immune to SCC in these conditions. This is a massive safety advantage.

The corrosion rate tells a similar story. In many industrial fluids, titanium corrodes at just 1/50th the rate of 316L stainless steel.

Then there is the weight. Titanium has the highest strength-to-weight ratio of any common metal. It’s just as strong as steel but 45% lighter. For large equipment like heat exchangers or tanks, this means lower shipping costs, easier installation, and less need for heavy support structures.

I worked with a chlor-alkali plant that was replacing its stainless steel heat exchangers every 3-5 years. The downtime and replacement costs were adding up. We helped them switch to Grade 2 titanium exchangers. I checked in with them recently. Fifteen years later, an inspection showed the exchangers had retained over 95% of their original wall thickness. The long-term value was undeniable for them.

Is titanium or 904L SS better for corrosion resistance of salt?

You are considering 904L, a "super" stainless steel, for a salty or seawater application. It’s a solid upgrade from 316L, but it can still fail unexpectedly in tight spaces or stagnant seawater conditions. Titanium offers more reliable, complete immunity in these situations.

For salt and seawater, Grade 2 titanium is better. While 904L stainless steel has good overall resistance, it is still vulnerable to crevice corrosion. Titanium is virtually immune to this specific and dangerous type of attack in saltwater.

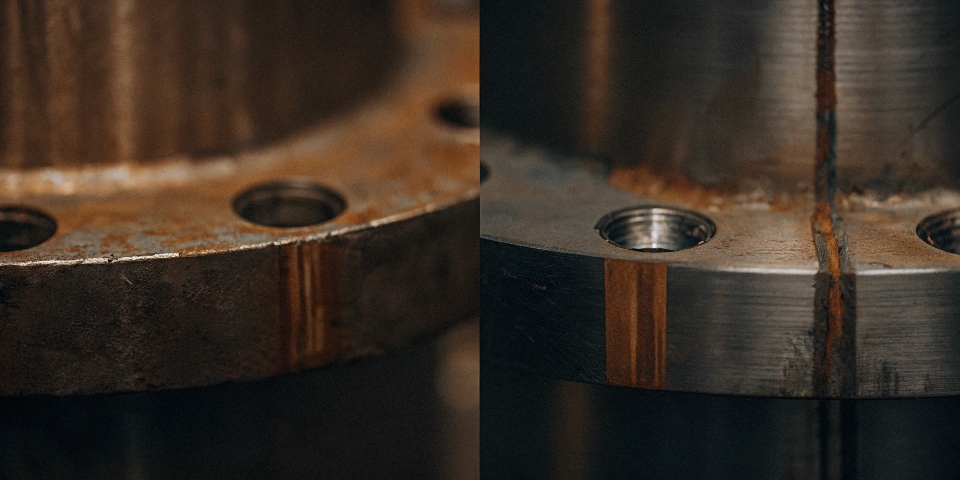

The Crevice Corrosion Challenge

Crevice corrosion is a tricky problem. It’s a localized attack that happens in tight spaces. Think about the areas under gaskets, washers, or bolt heads. In these crevices, the fluid becomes stagnant. The chemical balance changes, chlorides concentrate, and the protective passive layer breaks down, causing rapid corrosion.

904L stainless steel is designed to fight this. Its high nickel, chromium, and molybdenum content gives it a much better resistance to pitting and crevice corrosion than 316L. It’s a good material. However, it still has its limits. In warm seawater, especially in a crevice, 904L can still fail.

Grade 2 titanium does not have this vulnerability. It is considered fully resistant to crevice corrosion in seawater at temperatures up to around 80°C (176°F). In my experience, this provides a huge safety margin. We’ve seen 904L fail in plate heat exchangers using warm seawater for cooling. The titanium units in the same service continue to operate without issue. The critical crevice corrosion temperature of Grade 2 titanium is about 20°C higher than that of 904L, which is why it performs so much better in the real world. For Lisa, recommending titanium for any seawater application with flanges or gaskets is the safest call.

Conclusion

For superior corrosion resistance, especially in chloride-rich environments, titanium is the clear winner. Its long-term performance provides greater value, reliability, and safety for your most critical industrial applications.